Published on Nov 30, 2023

The transport modes like roadway, waterway and airway have been used by the mankind using land, water and air. In the past railways were assigned priority of developments, Because it was one mode of transport, which helped mass transportation of goods and passengers. Railways and roadways in India and abroad are in competition today for providing better transportation facilities. Air transportation is the most suitable transportation technique for long distance travels. So runway has very importance. Runway is a long and comparatively narrow strip, which is paved for small aerodromes.

Repair and resurfacing of runway is a complex activity, which requires comprehensive engineering evaluation, selection of suitable materials commensurate to problems and proper co-ordination of construction procedure and activities .It also demands setting up adequate quality planes and quality assurance methods. For runway resurfacing it is required to determine the nature and extend of deterioration and also the causes of deterioration. For this it is essential to carry out detailed study including overall projection evaluation so as to evolve suitable repair alternatives

The Air craft Classification Number/ Pavement Classification Number (CAN/PCN) system has been adopted by ICAO as the standard for the international reporting of air field pavement bearing strengths .The ACN- PCN system of rating air port pavements is designated by the international civil aviation organization (ICAO) as the only approved method for reporting strength. The ACN- PCN method came in to use in1981.

The ACN- PCN system is simple to use. Each air craft is assigned a number that expresses the structural effect on a pavement for a specified pavement type and a sub grade category. Each air port operating authority reports site pavement strengths using the same numbering system. The pavement is capable of accommodating unrestricted operations provide the air craft load number is less than or equal to the pavement strength number. Maximum tire pressure limitations may also be applied to some pavements which may further restrict certain air craft operations. The ACN is based on static application on aircraft loads to the pavement surface making them somewhat conservative in nature

The ACN and PCN are defined as follows:

• ACN is a number that expresses the relative structural effect of an aircraft on different pavement types for specified sub grade strengths in terms of a standard single wheel load

• PCN is a number that expresses the relative load carrying capacity of a pavement in terms of a standard single wheel load

• The system is structured so that a pavement with a particular PCN value can support, without weight restrictions ,an aircraft that has an ACN value equal to or less than the pavements PCN value

Most of the world’s paved roads are surfaced with asphalt, Asphalt is obtained by fractional distillation of petroleum crude, which gives good performance and durability under the most heavily trafficked conditions. Asphalt is obtained by fractional distillation of petroleum crude. These materials are also widely used in the construction of hard standing and parking areas for both light and heavy vehicles. They are therefore eminently suitable for use in the construction and surfacing of access roads, perimeter roads and vehicle parking areas on airfields.

Without hard paving, access may be difficult to the airfield, flying may be restricted in inclement weather or the facilities may not come up to the minimum standards required by the regulatory authorities for passenger carrying aircraft. The following areas on a typical airfield are likely to require hard paving:-

• runways

• taxi-ways providing access to runways

• aircraft parking, re-fuelling or servicing aprons

• hanger floors

• car, bus or commercial vehicle parking areas

• access roads

• edge drainage (French Drains) for runways and taxiways

In each of these areas different considerations apply. For example, runways require good skid resistance and surface water drainage for good braking, an even surface regularity to ensure passenger comfort and minimum risk of damage to delicate electronic components and adequate strength to support the high wheel-loadings of modern aircraft. Where jet-engined aircraft operate, freedom from loose particles is an additional, essential requirement to avoid the expensive damage that can be caused to jet-engines from ingestion of foreign objects (known as Foreign Object Damage or FOD). This term may also be used for “Foreign Object Debris” when referring to any detritus or loose particles on or near to runways or taxiways.

For aircraft parking areas the main requirement is adequate stability under high wheel-loadings; for paved areas where aircraft will undergo re-fuelling and servicing, the principal considerations are adequate stability under wheel-loads and heavy point loads from maintenance machinery as well as good resistance to oil spillage. Runways need to be constructed with sufficient strength to carry the moving aircraft. Runways require a higher degree of resistance to skidding and aquaplaning in view of the higher speeds involved. One means of achieving the latter, now employed on many major runways in the UK, is to use an open-graded Porous Asphalt surface course traditionally known as Porous Friction Course as the running surfacing. This acts as a drainage layer to prevent surface water adversely affecting aircraft tire grip on the surfacing in wet weather.

Beneath the Porous Friction Course a strong impervious binder course of Hot Rolled Asphalt or a dense Asphalt Concrete known as Marshall Asphalt is required laid to adequate falls. Alternatively the new surface course may be laid directly on an impervious existing surfacing.

When resurfacing work is being undertaken on runways, it is essential that the existing surfacing is of good regularity and laid to adequate falls or the levels are corrected by applying an appropriate regulating layer. This is of particular importance if a Porous Friction Course is to be applied and ensures that water is not held in the new surfacing to lead to heavy ice formation in winter.

Where relatively light aircraft are involved standard road surfacing materials, namely Hot Rolled Asphalt, close-graded/dense Asphalt Concrete or Stone Mastic Asphalt specified using the guidance from PD 66911 and the appropriate European Asphalt Standard will provide good durability and adequate performance. If Hot Rolled Asphalt is employed, a 35% stone content mix without the application of pre-coated chippings should give good performance and durability

Most runway resurfacing is carried out at night, with contractors given access for just a few hours. They do the work in short bursts, completing a section each night and reopening it the next day. It is not surprising, given these constraints, that designers and contractors tend to stick with tried and tested mixes for the new runway surface – usually Marshall Asphalt, a continuous graded aggregate mix that gives a harder surface than traditional hot rolled mixes.

Nynas has, over the years, developed a number of products that can be used in runway surfacing and other heavily trafficked areas within airports. These include binders with high resistance to damage by fuel oils and de-icing fluids – a major issue for airport managers – as well as binders for thin surfacing and foam mixes.

One fuel damage resisting product Nyguard , was used at Bristol Airport to bring two redundant runways back into use as taxiways and for aircraft refueling and parking(fig.1). These ancillary areas are seen as lower risk.

Fig.1 Nyguard, was used at Bristol airport to bring two redundant runways back in to use

Nynas has developed the product further to produce Nyguard HR(fig.2), a hot mix binder specifically designed for heavy duty areas like airfields, docks and bus bays. As well as its fuel damage resisting properties, the binder gives cohesion values up to five times greater than equivalent paving grade bitumen, making it much more resistant to shearing forces and resulting scuffing, tearing and deformation.

Fig.2 Nyguard HR, a hot mix binder specifically design for heavy duty areas

One issue that may make airport owners more willing to look at non-traditional mixes for runways is sustainability. With local authorities setting targets for recycling, and commercial firms increasingly aware of waste and energy consumption, there is increasing pressure to reuse material in runway resurfacing.

In a recent contract at Liverpool Airport, Tarmac reused runway planings for sections of recycled pavement. These areas – the outer strips of the runway – were re-constructed using Nyfoam, a binder specifically developed by Nynas for foam mixes and used last year on the UK’s largest road recycling contract on the A38 in Devon.

The successful application of the technique at Liverpool is likely to lead to other airports considering recycling for future resurfacing projects.

While Nynas’ specialist products have so far mainly been used on ancillary areas, such as taxiways and parking bays, the company also has experience of supplying specialist materials for main runways. At Exeter Airport, for example, its Nypol TS polymer modified binder was used by Bardon in the construction of a “Super AirMat” runway – a thin surfacing alternative to traditional Marshall Asphalt.

Super AirMat contains a 10mm nominally sized grit-stone with a very high polished stone value to give the surfacing a high level of grip. The Nypol TS is designed to give good adhesion and cohesion with the stone, and extra durability comes from adding cellulose fibres to the asphalt mix.

The Super AirMat mix was designed specifically for airfields, and is laid in a single pass, making it a very efficient way to surface large areas in a relatively short time.

The most common methods of pavement retexturing are:

• High Water Pressure,

• Ultra High Water Pressure (Track Jet),

• Chemical,

• Shot Blasting,

• Mechanical Process.

Rubber is removed by means of rotary devices that move along the surface as it cleans. This is done utilizing up to 30 gallons of water per minute at pressures of between 100 to 1,000 bar . The water that penetrates the surface effectively cleaning rubber deposits creates an hydraulic effect. This helps to increase the frictional values and surface texture of the pavement. A combined suction part or a sweeper that picks up the rubber debris during its operations usually accompanies it. This allows for the pavement to be easily and quickly returned to operations and is especially advantageous in airport operations where time constraints and short possession time is common.

Benefits of using this technique are:

• The speed at which rubber is removed (1,200 m² per hour are claimed).

• The cost efficiency of the process (water is generally provided).

• The improved friction characteristics of the pavement due to penetration of the water and the removal of rubber.

• The ease of getting off the runway in the event of an emergency.

• Its usage is independent of weather and can be operated in cold, damp wintry conditions.

• Noise from the operation requires the wearing of hearing protection.

• Eye protection should also be worn in the vicinity of the machine while in operation.

• Appropriate disposal of waste material is required.

• Does loosen surface matrix encouraging the loss of fine materials.

• Cleaning rate is 70% with one run.

• Heavily damages certain asphalt types like antiskid.

• Damages grooves and pavement surfaces over time (8 years).

• Damages sealing.

• Cannot be used to clean AGL.

HPW is most effective on sprayed seals and asphalts that show loss of texture due to flushed bitumen. This results in safer operating conditions for pavements.

TrackJet (Ultra High-Pressure Water blasting)

The TrackJet, an Ultra High-Pressure Water blasting machine developed by Bernd Weigel in Germany, is widely used at BAA airports and other leading airports in Europe, as well as European highways for retexturing and paint marker removal.

Through its modern technology of retexturing, this machine has consistently removed 100% of rubber build-up and pavement markings from pavements without touching the pavement micro or macro texture. It utilises a nozzle system that is truck mounted, applying very little water at very high pressure through a unique computer-controlled system.

This enables an environmentally friendly and most effective maintenance for all kind of surfaces. Cost savings through increasing rubber removal intervals without damaging or destroying the aggregates on the pavement surface result in an increased pavement life.

Benefits of this technology are:

• Optimum treatment with care of pavement surface.

• Reduces direct and indirect renovation cost by prolonging cleaning and resurfacing cycles.

• Applicable to all kinds of surfaces; for example asphalt, anti-skid, petro-grip and concrete.

• Best possible friction values, therefore prolongs the time interval till next cleaning.

• High environmental compatibility is reached due to very low water consumption and very low eroded road/runway substance volume.

• No damage to grooving, runway lighting systems, marker paints and joint sealing.

• Clearing out of expansion joints.

• Only needs one personnel to operate.

• The ease of getting off the runway in the event of an emergency; runway can be evacuated in 3 minutes leaving the working area tidy and surface like new.

• Its usage is independent of weather and can be operated in cold, damp wintry conditions or warm temperatures (2 to 40 degrees centigrade).

• High environmental care due to extremely low water and fuel consumption; the Track Jet works with clean water without chemical adhesives and requires only 10 to 20% of the water and 30% of the fuel HPW systems normally require.

• Low expenses with waste removal, because no chemical is used to separate the rubber waste from waste water.

This system is also universally suitable for cleaning sealing joints, concrete renovation, cleaning of steel and concrete areas, apron areas and oil spill removal.

Disadvantage of systems:

• Appropriate disposal of waste material is required.

• Some airport staff claims that up to 800 m² per hour cleaning (but 100% rubber removed) is too little.

Environmentally friendly chemicals have been developed that are safe and effective in cleaning rubber from contaminated surfaces. This is done by spraying the chemicals onto the pavement surface and then scrubbing, brushing and working them into the rubber deposit over several hours. The chemicals break down the polymerized rubber into a soft jelly like substance.

The substance is then flushed off the runway by water blasting when the process is completed. During this process, the runway cannot be reopened until the process is completed due to the runway surface being slippery.

The debris cannot be swept up using conventional sweepers since the chemicals will react with the rubber seals within the sweeper. Even though the debris is considered to be biodegradable, the chemical is not and as a result, the usual method of clean up is: flush the soapy residue off the pavement surface onto the surrounding soil after completion of works.

Over time, the debris accumulates and may eventually cause an environmental problem requiring remediation. The cost of chemical removal is usually double the cost of HPW and Track Jet due to the cost of the chemicals.

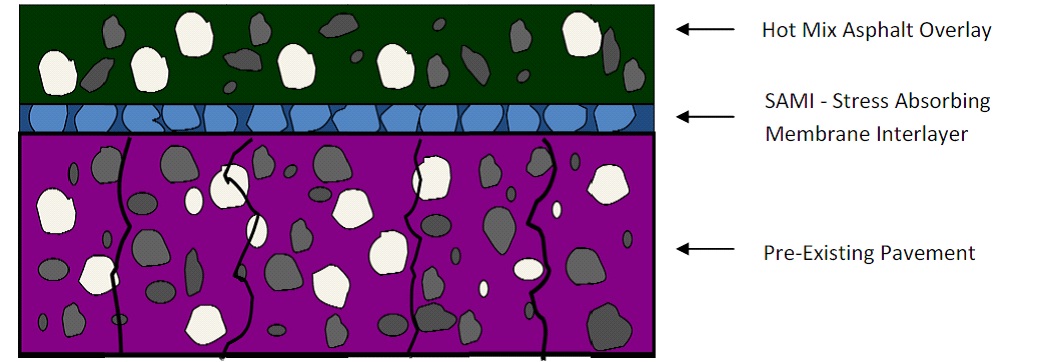

Asphalt interlayer system consist of a wide variety of products and processes, each with unique benefits and specific placement methods to ensure good adhesion to the underlying pavement. The products may be classified in a number of categories such as; sand asphalts, grids, nonwovens, steel reinforcements and SAMIs.

In general, a SAMI is placed on top of an existing pavement and subsequently capped with a hot mix asphalt overlay (Fig.6).Its purpose is to delay the propagation of cracking that originates in the pre-existing pavement that will eventually reflect through to the new surface layers. Cracking in the surface layers allows penetration of water, salt and other deleterious materials that can accelerate the deterioration of the entire pavement structure once it penetrates the aggregate base.

Fig: 6. SAMI within the pavement structure

“A saturated asphalt concrete is typically unaffected structurally by water unless the asphalt aggregate is stripping prone. In contrast, a saturated base aggregate loses about 40% of its strength when saturated.”( source: Pavement Preservation Task Group of Caltrans)

In effect each crack will allow a certain amount of water to enter the road base hence negatively impacting the original engineered design. An effective SAMI should therefore; provide additional tensile strength to the pavement to combat reflective cracking, be flexible enough to allow it to move within the pavement structure as well as providing a waterproof barrio for the ingress water from the surface to the pre-existing pavement.

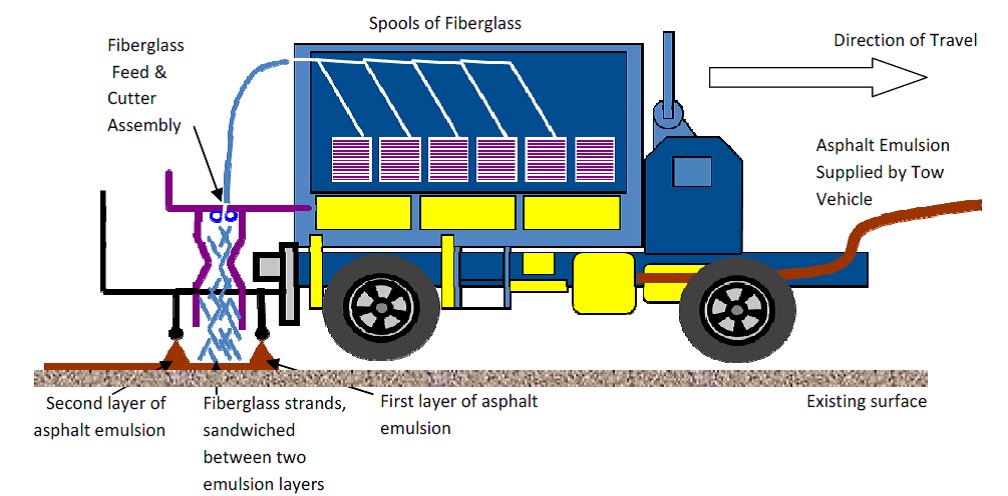

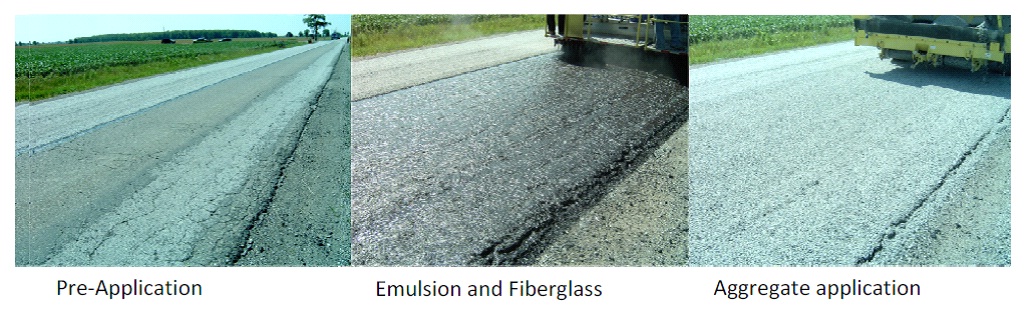

FiberMat is a flexible, waterproof membrane that incorporates asphalt emulsion and fiberglass strands to combat reflective cracking, meeting all three requirements of an effective SAMI. Patented equipment, developed specifically for the FiberMat process, ensures even distribution of the materials and precise computer controls to allow adjustments in application rates while the machine is in motion.

This equipment is contained within a trailer that houses several spools of fiber glass, the patented cutter assembly system, an asphalt emulsion pump and distribution spray nozzles, plus the computer system that controls the application rate of each component (figure7) . The unit is pulled by an asphalt emulsion tanker, connecting the output lines of the tanker to the Fiber Mat machine’s emulsion pumping system

Fig:7. The fiberMat , Application System

The fiberglass strands are pneumatically blown between two separate layers of asphalt emulsion (figure8) ensuring complete and even coverage of both fiberglass and asphalt emulsion(figure9).

The even distribution of emulsion and fiberglass is achievable in a swath up to 4m wide (easily covering an entire lane width).Computer synchronized nozzles and cutters allow the operator to vary the application width to accommodate changes in pavement width, tapered sections and turning lanes. It is possible to place FiberMat as narrow as 1m to a maximum of 4m (150mm increments)

To complete the process, it is necessary to imbed a layer of aggregate in to the second layer of asphalt emulsion. Aggregate is placed with a traditional chip spreader and seated using pneumatic rollers. The purpose of the aggregate layer is to protect the newly constructed membrane from vehicular traffic and construction equipment. The completed FiberMat (SAMI) is capable of accepting traffic within 20 minutes, and should be overlaid with hot mix asphalt prior to the onset of freezing temperatures.The unfinished road, FiberMat and aggregate.

The entire ‘ train’ of equipment consists of the emulsion tanker, FiberMat trailer, chip spreader, aggregate trucks and rubber tire rollers

Runway rehabilitation scheme requires in-depth study of problems of formulate repair scheme and to choose suitable materials and techniques for repair. Use of new materials like modern asphalts, SAMI(FiberMat Type B) to delay propagation of reflection cracks are found to be a lasting solution. However, its long-term performance in context of Indian climatic conditions is yet to be established and proven. However, no guidelines are available with respect to various methods. These are the fields, which needs further studies. In future, these materials are likely to find extensive usage in highway and runway work.

Devendra Kumar., “Runway Maintenance Using modern Techniques”, IRC Journal of Indian Highways, March 2005, pp.31-39

Pawan Kumar and A K Sriinivastave., “Glass Fibre Reinforced plastic”, Civil Engineering Construction, November 2002,pp.45-50

ICAO Aerodrome Design Manual Part 3

Defence Estates Specification 013 – Marshall Asphalt for Airfields

| Are you interested in this topic.Then visit the below page to get the full report |