Published on Nov 30, 2023

Manufactured sand is a term used for aggregate materials less than 4.75mm and which are processed from crushed rock or gravel. Due to booming of construction activities in our country, natural sand resources are increasingly depleted and its cost is becoming increasingly high. This seminar was, therefore, conducted to study the influence that manufactured sand have in compressive strength of concrete, to compare the cost of different mix compositions and to assess the prospects of using manufactured sand as replacement of natural sand The cost comparisons results also have shown that using manufactured sand in partial or full replacement to natural sand doesn’t cause any significant cost variation. It has been found also that use of manufactured sand is more suitable for high strength concrete production. It can therefore, be concluded that when the availability of natural sand is scarce or in cities where the price of natural sand is as expensive as manufactured one, manufactured sand concrete mix is a viable and better alternative to the use of natural sand.

Now, there exhibits some delays in the building construction due to the shortage of sand. The demand for sand has been ever increasing with the development of building industry. As a result, it has been noticed the over exploitation of river sand causing serious environmental problems. At least during the past five years, this problem has been discussed by the concerned scientists and engineers. One of the main objectives of these discussions was the identification of potential sources of river sand alternatives. Many environmental problems arises due to the taking of excess amount of sand from rivers. So Government banned this upto a certain extent. To overcome these problems faced by the people there are other types of building materials like M.Sand, Volcanic glass and Gypsum. These are all building materials which are used for a long time.

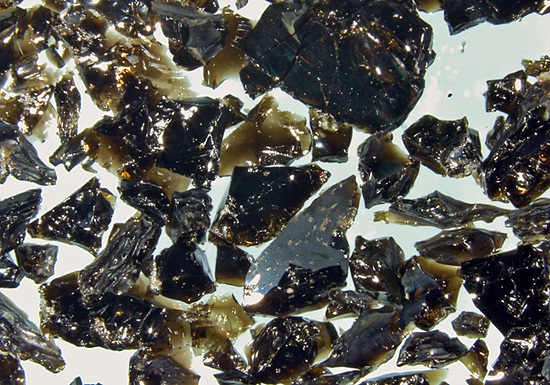

M-Sand is manufactured sand, obtained from specific hard rock (granite) using the state-of-the-art International technology. Its numerous advantages over river sand have made it a favorite and a "Must-to-Use" with quality conscious builders.

Poabs is always been the first to introduce these technological bliss for the good use of the construction industry in South India. In line with the manufacture of sand in bulk quantity, Poabs have procured the world's best and state of the art equipments and installed them at various safe stations in Kerala complying with every scientific parameters set for producing Manufactured Sand(M-Sand). Modern and imported machines VSI(Vertical Shaft Impact) are used by Poabs to produce M-Sand, ensuring to IS 383 ZONEII. For quality control, Poabs has engaged in a scientific tie-up with the RND lab and department heads of Trivandrum Engineering College who rigorously and constantly monitor our production at every stage. This exceptional kind of technical support always assures us to maintain consistency in quality as well as to upgrade our technology from time to time.

The particle shape of the aggregates is very important for making concretes. It is a well known fact that the sand having cubical particles with grounded edges gives higher tensile strength and compression strength to the concrete. The grains should be of durable material and the size of the grains must be such that it should give minimum voids. The presence of clay and slit is avoided since it retards the setting of the cement and making mortar. Experiments shown that considerable variations in strength of mortar may occur owing to form and variety of the sand particle. The strength of mortar may differ by about 50% of average. It is not possible in river sand that all particles should be of higher strength. This can be achieved only by making sand with the help of machines. In machine-made sand, we can use the raw material of higher strength.

There is discrepancy in the river sand for two loads lifted from same source. Hence to achieve consistent quality, each truck of sand should be tested. Moreover the sand has to be sieved to remove stones, slit and clay. In routine average wastage of sieving are about 35% and extra labour cost involved. Whereas Poabs M-Sand is ready-to-use-sand with no wastage since it do not have organic impurities. The superior shape and gradation of Poabs M-Sand ensures high strength concrete with significant savings in cement.

M-Sand is crushed aggregates produced from hard granite stone which is cubically shaped with grounded edges, washed and graded with consistency to be used as a substitute of river sand. Vasthu shastra says building material must be free from traces of human body or animal. M-sand is free of such material and is produced by crushing hard granite stone when compared to river sand that is produced naturally from weathered rock. M-sand is superior quality manufactured sand with international standards.

Volcanic glass is the amorphous (uncrystal) product of rapidly cooling magma. Volcanic ash and lava also form rich soil, while hot rocks heat under water. Volcanic ash also serves as a natural resource for construction and industry. Lava and tuffs can be cut into blocks and used as stone for building. They have enough strength for high buildings. Stone buildings are light weight, resistant to weathering and good insulators. Concrete too was discovered by Romans who mixed granular volcanic ash with lime cement to create a new water-resistant material with superior strength . It was this substance that allowed the Romans to build fantastic edifices, waterworks, aqueducts, roads, harbors, under water structures and light houses. It is still used in concrete constructions today.

Among its advantages are less need for structural steel reinforcement, smaller. They are porous, Froth-like volcanic glass which come in various colours and are found in the western united states.

Light weight concrete weighing from 35 to115 pound per cubic foot has been used in the United States for more than 50 years. The compressive strength is not as great as ordinary concrete, but it weathers just as well. Among its advantages are less need for structural steel reinforcement, smaller foundation requirements, better fire resistance and most importantly the fact that it can serve as an insulation material. It can cost more that sand and gravel concrete and it may shrink more upon drying.

Light weight concrete may be made by using light weight aggregates or by the use of foaming agents such as aluminium powder, which generates gas while the concrete is still plastic. Natural light weight aggregates include Pumica, Scoria, Volcanic linders, tuff and diatomite. Light weight aggregates can also be produced by heating clay, shale, slate, diatomaceous, shale, perlite, obsidian and furnace slag that has been specially cooled can also be used.

The rock from which perlite is manufactured has a structure resembling tiny pearls and when it is heated it expands and breaks into small expanded particles the size of sand. Concrete made with expanded perlite weights between 50 to 80 pounds per cubic foot and is a very good insulating method.

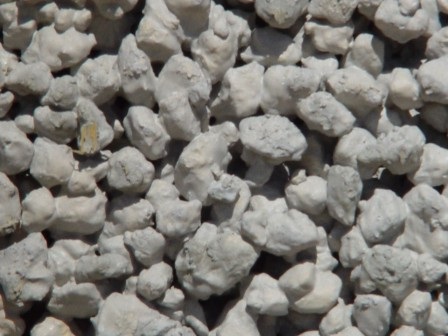

Pumice is an extremely lightweight rock formed when volcanic lava cools so quickly that most of its volume is comprised of tiny bubbles of trapped gases. Pumice-Crete is made of three ingredients: pumice as aggregate and just enough portland cement and water to hold the pieces of pumice together. The insulating value of Pumice-Crete comes from both the tiny bubbles within the sponge-like pumice itself and the larger air spaces between the pumice pieces, once the whole wall is sealed by a plaster coating. Pumice-Crete is poured into forms to cast walls in place, then a solid concrete bond beam is poured atop the walls to hold connectors for the roof system. With minimal wall thicknesses of at least 14 inches, Pumice-Crete is strong enough to need no additional structural support for most one- or two-story buildings

Pumicecrete has been used in constructing buildings for many years. It is simply concrete that uses crushed volcanic rock as an aggregate rather than conventional sand and gravel. Both pumice and Scoria when used in this fashion, render a product that is much lighter than concrete.

Pumice-Crete walls are much more consistently insulated than conventional, stud-and-batt walls, and they allow far less air infiltration

Pumice-Crete uses relatively little portland cement, and the pumice aggregate is collected from shallow deposits found in volcanic areas around the world. In many areas, all of the needed materials are available locally

Pumice-Crete can be delivered pre-mixed in trucks or mixed on-site.

Unlike wood, Pumice-Crete will not burn, rot, or get eaten.

The uniformly coarse Pumice-Crete surface allows a stucco finish without the use of stucco netting.

The light weight of Pumice-Crete allows the use of lightweight forms, made of half-inch plywood and 2x4s, that can be saved for use on another building project.

Thick, poured walls allow for interesting architectural choices that highlight their massive, earthy quality.

Gypsum is a light weight material which is formed as the result of evaporating sea water in massive prehistoric basis. In terms of its chemical composition, it is calcium sulphate Di-hydrate (CaSo4.2H2o) and inherently contains 21% water by molecular weight. Gypsum products have been used for centuries in the construction space and are the material of choice because of gypsums unique properties. It has excellent insulation properties both thermal and acoustic and can offer very good passive fire protection, moisture resistance, impact resistance and vapour control when used in combination with the right systems.

In recent years, the construction sector has witnessed a number of new trends, technology advancements and innovations across applications all aimed at making construction faster and delivering higher performance. However, very few would have imagined that the substitute for the generations old method of sand cement surface plastering will be an even older method of plastering. ie, gypsum plastering. Gypsum has proved to be a miraculous material aiding interior construction

The most significant use for gypsum is for wallboard and plaster products. All modern homes in North America and other developed countries use a great deal of wallboard for interior walls. The United States is the world’s leading consumer of wallboard at over 30 billion square feet per year. Some gypsum is used to make Portland cement, and some is used in agricultural applications. A small amount of very pure gypsum is used in glass making and other specialized industrial applications.

When a wall is constructed with brick or block, they are finished with a coat of plaster which is called internal plastering. Internal plastering has traditionally been done through a process of Sand-cement plastering finished with pop pruning.

Wash sand mixing in cans ensures zero wastage

Site mixing

No quality control

Water curing for 7 days minimum no water curing.

Coat of leveling material required before painting (POP) dries in 3 days

No Shrinkage cracks

Direct application on brick, block or RCC, no separate finishing product required

Smooth finish

Ready to painting.

The superior shape, proper gradation of fines, smooth surface texture and consistency in production parameter of chemically stable sands provide greater durability and higher strength to concrete by overcoming the deficiencies like segregation, bleeding, honey combing, voids and capillary.

The alternatives of sand has greater workability than the original river sand

1. Foundation design by Nainan.P.Kurian.

2. IS 15284(part 1)-2003 design and construction for ground improvement- Guidelines (Part 1) - Stone columns.

3. IS 13094-1992 Ground improvement-techniques on weak soil.

| Are you interested in this topic.Then visit the below page to get the full report |