Published on Apr 02, 2024

With the rising demands of power , better performance & fuel economy in automobile vehicles, engineers do many research & finally they got success in the form of a new breed of engines the ‘W Engines’. One of the first W engines was a three-cylinder (W3), built by Anzani in 1906 to be used in motorcycle. The 1917 Napier Lion aircraft engine was an early W12 engine.

After many years of research Volkswagen Group created the first successful automotive W engine, with the introduction of itsW8 engine (as a testbed for W12). The W12 combines two narrow-angle VR6 engines around a single crankshaft for a total of four banks of cylinders. For this reason, the four-bank configuration is sometimes, and more accurately, referred to as a "VV" or "VR", to distinguish it from the traditional three-bank "W" design. Volkswagen Group went on to produce a W16 engine prototype which produced 465 kilowatts (624 bhp).

A quad-turbocharged version of this engine went into production in 2005 powering the 736 kilowatts (987 bhp). The major advantage of these engines is packaging; that is, they contain high numbers of cylinders but are relatively compact in their external dimensions. In 2006, the Volkswagen Group-owned Bugatti produced an impossible missile, the Bugatti Veyron EB16.4, a supercar; with an 8.0 litre W16 engine. This had four turbochargers, and it produces motive power output of 736 kilowatts (987 bhp) at 6,000rpm. It utilises four valves per cylinder, 64 valves total, with four overhead camshafts. This car is now the fastest production car of world with unbelievable speed of 432kph and may be it goes on in coming years.

• The constantly rising demands regarding performance, running comfort and fuel economy have led to the advancement of existing drive units and the development of new drive units.

• The new W8 as well as the W12 engines are representatives of a new engine generation - the W engines.

• Large numbers of cylinders were adapted to the extremely compact dimensions of the engine. In the process, more attention was paid to lightweight design.

• With the aim of building even more compact units with a large number of cylinders, the design features of the V and VR engines were combined to produce the W engines.

• As with the V engines, the cylinders are distributed to two banks. In the W engines, these banks of cylinders are aligned at a V-angle of 72° in relation to one another.

• When the W engine is viewed from the front, the cylinder arrangement looks like a double-V. Put the two Vs of the right and left cylinder banks together, and you get a W. This is how the name "W engine" came about.

To illustrate the principle of the W engine cylinder arrangement, let first look at conventional engine types.

• Represents the earliest development level in engine development. The cylinders are arranged in-line vertically above the crankshaft.

• Advantage: Simple design

• Drawback: Large numbers of cylinders result in very long units unsuitable for transverse mounting.

• To make engines shorter, the cylinders in the V engines are arranged at an angle of between 60° and 120°, with the centre lines of the cylinders intersecting with the centre line of the crankshaft.

• Advantage: Relatively short engines

• Drawback: The units are relatively wide, have two separate cylinder heads, and therefore require a more complex design and a larger engine compartment volume.

• The need for a powerful alternative suitable for transverse mounting for use in lower mid-range vehicles saw the development of the VR engine. Six cylinders, offset at a V-angle of 15°, are accommodated in a fairly slender and very short engine block. Unlike previous designs, the engine only has one cylinder head.

• The engines of the W family are a combination of two "VR banks" based on a modular design principle. The cylinders of one bank have an angle of 15° relative to each other while the two VR banks are arranged at a V-angle of 72°.

• Two compact VR engines from the VR series are combined to produce a W engine. The result is a series of compact petrol engines ranging from the W8 to the W16.

• Numerous components of the VR and W series are identical, e.g.:

- Valves, valve springs and valve seat inserts

- Roller rocker fingers

- Valve clearance compensating element

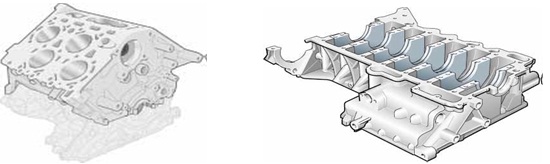

• The crankcase comprises two components: the crankcase upper section and the crankcase lower section. The upper section contains, among other things, the cylinders and the upper bearing cover halves of the crankshaft. The crankcase lower section is designed as a bearing support and carries the lower bearing cover halves.

The crankcase upper section

• The "aluminium" crankcase upper section is made of a hypereutectic aluminium-silicon alloy (AlSi17CuMg).

• Use of this alloy eliminates the need for additional cylinder liners or a plasma coating for the purposes of cooling and lubricating the cylinder surfaces as the material already has sufficient natural strength and thermal stability.

The crankcase lower section

• The crankcase lower section is a bearing support with integral bearing seats.

• The bearing support is also made of aluminium. It serves as a frame structure for the lower crankshaft bearing covers. These bearing covers are made of grey cast iron and are also embedded when the bearing support is cast.

• They are located on the pressure side of the crankshaft and give the crankshaft bearing the strength it requires.

• The bearing support is attached to the crankcase upper section by 4 bolts per bearing cover.

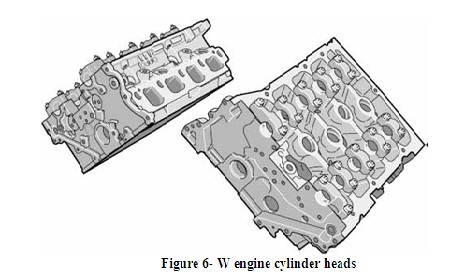

• The W engines have two aluminium cylinder heads with two overhead camshafts apiece. The injectors are inserted into the cylinder heads.

Figure 6- W engine cylinder heads

• Each of the cylinder heads in the two W engines has an intake camshaft and an exhaust camshaft with camshaft adjusters attached to their end faces.

• Due to the cylinder arrangement, short and long valves as well as short and long inlet and exhaust ports alternate with one another.

The W 16 Engine-

• A W16 engine is a sixteen cylinder piston internal combustion engine in a four-bank W configuration.

• All W16 engines consist of two ‘double-row' banks of eight cylinders, coupled to a single crankshaft.

• Volkswagen Group is the only automotive manufacturer currently producing W16 engines. Volkswagen Group's design is a stretched form of its W12 engine, which is itself based on technology from its VR6 engine.

• In the W16, each side is made up of eight cylinders, but the 'bank' angle is increased to 90 degrees.

• The narrow angle of each set of cylinders allows just two overhead camshafts to drive each pair of banks, so just four are needed in total. For this reason, the engine is sometimes described as a WR16.

• The Bugatti Veyron 16.4 is the fastest and most expensive street-legal production supercar in the world, with a proven top speed of over 400 km/h (407 km/h or 253 mph).

• The Bugatti Veyron features a super W16 engine—16 cylinders in 4 banks of 4 cylinders.

• It reached full production in September 2005.

• It is named after racing driver Pierre Veyron, who won the 24 hours of Le Mans in 1939 while racing for the original Bugatti firm.

• Bugatti once again claimed the land speed record for production cars on July 4, 2010 with the Veyron Super Sport prototype.

• At the hands of Bugatti test driver Pierre Henri Raphanel, the Super Sport managed runs of 265.9 and 269.8 mph (approx 432kph).

W Engine with their successful story created a new era of powerful & efficient engines with better fuel economy. From 1906 to present there is a constant increase in power and performance of W engines. Volkswagen is the only car manufacturer in the world, currently producing W engines. Volkswagen working in this field since 1998 produced many W engines e.g. W8, W12 and then W16. W16 engine is currently the most powerful Engine in the world which when installed in Bugatti Veyron gives running speed of 432kph.

So as centuries goes on people’s demand for supercars also increases which led many automobile companies to do research and produce more powerful engine. Hope the successful story of Volkswagen, in producing powerful engines continues in the coming years.

[1] "Department of Energy, Annual Energy Review 2003," DOE/EIA-0384, 2004, Energy Information Administration (EIA), Washington, D.C.

[2] Krivts, I. L., and Krejnin, G. V., Pneumatic Actuating Systems for Automatic Equipment : Structure and Design, CRC/Taylor & Francis, Boca Raton 2006.

[3] Fronczak, F. J., and Beachley, N. H. "An Integrated Hydraulic Drive Train System for Automobiles," Fluid Power, R. Heron, ed., Elsevier Applied Science,London, 1988, pp. 199-215.

| Are you interested in this topic.Then mail to us immediately to get the full report.

email :- contactv2@gmail.com |