Published on Nov 30, 2023

Rapid urbanization and industrialization in the developing countries like India, pose severe problems in collection, treatment and disposal of effluents. This situation leads to serious public health problems. Unmanaged organic waste fractions from industries, municipalities and agriculture sector decompose in the environment resulting in large scale contamination of land, water and air. These wastes only represent a threat to the environmental quality but also possess a potential energy value which is not fully utilized despite the fact that they are cheap and abundant on most parts of the world. In order to product the water resources from onslaught of these wastes, it is necessary to provide adequate treatment to reduce their pollution potential. For biodegradable impurities, the natural choice is biological treatment, which could either be Aerobic or anaerobic.

In India, sugar is essential item of mass consumption and the cheapest source of energy, supplying around 10% of the daily calorie intake. It is interesting to note that India ranks 6th in per capita consumption to human body with Brazil being the highest per capita consumption of sugar at 57.6 kg per capita all around the world. About 60% of the crop in India is grown in sub tropical region, while 40% of the crop is grown in tropical region (Tamil Nadu, Karnataka, Maharashtra, Madhya Pradesh). Maharashtra and Uttar Pradesh together produce 60% of the sugarcane grown in India with state producing almost equal amount. On average, crop yields are better in the sub tropical region due to less variability in the mean monthly temperature. India’s sugarcane yield is estimated at 65,000 kg per hectare, higher than the global average of around 63,000 kg per hectare.

Keywords : Waste Water, Reactor, Anerobic

Sugar industry wastewater was treated in a UASB reactor seeded with non granular an aerobically digested sewage sludge.

A laboratory scale UASB reactor was fabricated from acrylic pipe of 90 mm internal diameter. The overall height of the reactor was 1300 mm, one inlet at 50 mm from the bottom of the reactor was provided for the influent.

Five sampling ports are provided at a height of 145 mm from the bottom of the reactor at 180mm c/c. the effective volume of the reactor was 7.95 liters.

The reactor was started with an initial organic loading rate of 0.5 g COD/L.d at aconstant hydraulic retention time of 48 hrs.

On the day 36 the COD concentration of increased to 2000 mg/L at HRT of 24 hrs resulting in increase of OLR to 2 g COD/L.d.

UASB design is feasible to treat sugar industry wastewater efficiently up to an Organic loading rate of 16 g COD/L. d. with a COD removal efficiency of 89% at much lower HRT of 6 hrs. Methane rich (more than 75%) biogas can be produced at the rate of 4.66L/ d.

Treatment of Sugar industry wastewater by Baffle wall Reactor.

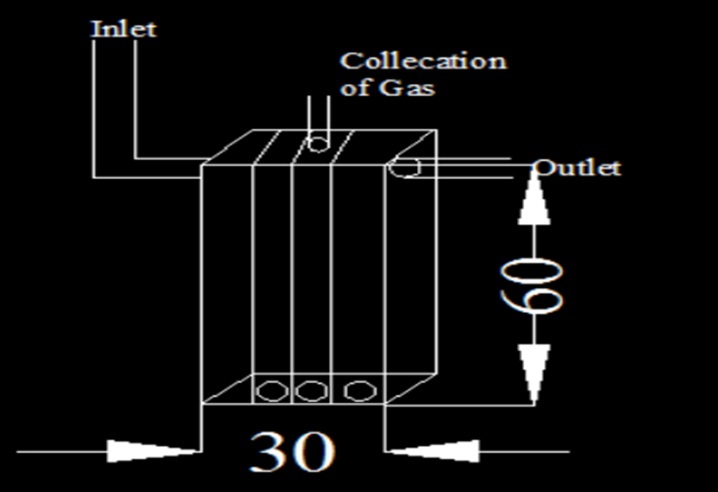

Fabrication of Baffle wall reactor.

To study the Baffle wall Reactor for treatment of sugar industry wastewater.

To study the optimum Hydraulic Retention Time (HRT).

To study the variation of COD content with respect to the HRT.

To study the variation in pH during treatment period with respect to the HRT.

Sugar industry wastewater was fed into the baffled reactor through the inlet, feeding tank is having a height of 70 cm from the inlet of baffle reactor. Baffled wall is provided with the holes of 1 cm diameter. At the top and bottom of the baffle wall from one side to another side. Initially the effluent has been filled in the first chamber the velocity of the flow is reduced due to the baffle wall and in the next two chambers under goes the anaerobic reaction.

The wastewater coming from the baffle wall reactor was transferred to trickling filter from the top. The wastewater was trickled on filter media (jute).

The filtered water is then collected in the bottom collecting tank.

The industrial wastewater was treated itself repeatedly in the Baffle wall Reactor, which means it involves simple, reliable, biological process. The Baffle wall Reactor had sufficient reduction in the velocity of the flow, sufficient air circulation naturally. Handling of the excess sludge is not a problem because the amount sludge produced is less. Therefore, the proposed biological treatment process appears to be promising wastewater treatment method for industrial wastewater treatment with respect to the removal of COD.

From our results we observe that the COD is reduced from 2500mg/ltrs to 1040 mg/ltrsat 48 hrs of HRT, BOD is reduced from 1900mg/ltrs to 800 mg/ltrs at 48 hrs of HRT, & the pH is reduced from 7.23 to7.20 at 48 hrs of HRT. Hence the optimum HRT of the Baffle wall Reactor is 48 hrs.

The efficiency of the Baffle wall Reactor is about 43%.

Hence the sugar industry wastewater can be effectively treated by Baffle wall Reactor.

In future this reactor can study:

By changing the filter media.

By varying the depth of filter media.

By varying the concentration of loading.

By varying the HRT.

By varying the dimensions of the reactor.

By increasing the number of baffle walls.