Published on Nov 30, 2023

Textile and clothing industry is one of the largest and oldest industries present globally. The type of dyes and chemicals used in the textile industry are found to be differing depending on the fabrics manufactured. Textile industry is very water demanding, it uses fresh water for various activities in manufacturing process. Textile industries are one of the most polluting sources in terms of the volume and complexity of its waste water discharge. The waste water generated from textile industry is generally warm, Alkaline, Strong smelling and colored by chemicals used in dyeing processes. On an average 125-150L of water is required to produce 1kg of textile wastewater.

wastewater generated from textile industry consists of various types of dyes used in manufacturing processes, these dyes has high molecular weight and complex structure. Also it has high solubility in water makes a major impact o environment when it is discharged to water sources.

More over a typical textile waste water is known to have various pH solutions, high temperature, high chemical oxygen demand(COD),high biochemical oxygen demand(BOD), high suspended solids (SS) and also characterized by high level colour imparted by residual dyes. As industrialization develops, wastewater treatment has become a major issue in recent years and wastewater is not only the main maker of environmental imbalance but also furnish to the decrease of fresh water source of earth. Presently, there is a demand for new and environmental friendly wastewater treatment technology as the fresh water is polluting.

Keywords : Textile and clothing, biochemical oxygen demand, textile wastewater.

To study the feasibility of treating textile wastewater by combined coagulation, electrocoagulation and adsorption process.

1. To investigate the effectiveness of coagulation treatment using natural coagulant cactus on removal of Turbidity.

2. To determine the optimum electrocoagulation condition for the removal of colour and COD using suitable electrodes.

3. To investigate the potentiality of Eucalyptus Bark as an adsorbent for the treatment of textile wastewater in removing colour.

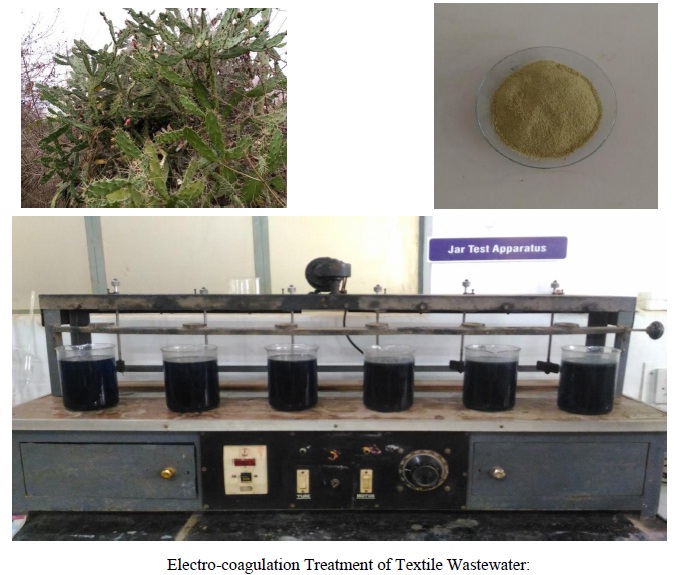

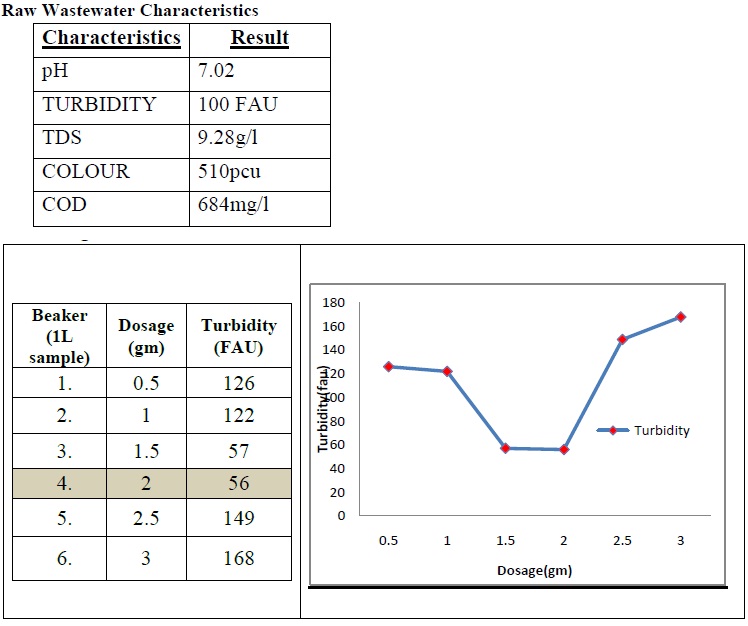

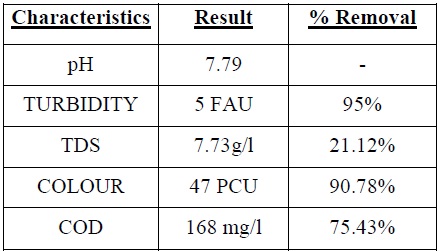

For this study, Cactus (opuntia) has been chosen as coagulant because it is naturally available and may function as an effective and less expensive coagulant in removing solids and turbidity. The coagulation studies was conducted in a jar test apparatus with six beakers of 1L capacity each. Each of the beakers contains 1L of settled textile wastewater. The coagulant Cactus (powder form) is added into the beakers without pH adjustment. Rapid mixing at 150rpm for 4 min followed by slow mixing at 40rpm for 20 min. The flocs was allowed to settle for 1h and the supernatant was carefully extracted by pipetting just below the surface of settled water. Afterward, the supernatant is examined for turbidity of the treated wastewater. Finally, after coagulation, electrocoagulation process with suitable electrodes was performed on the supernatant. The experiment was performed at room temperature.

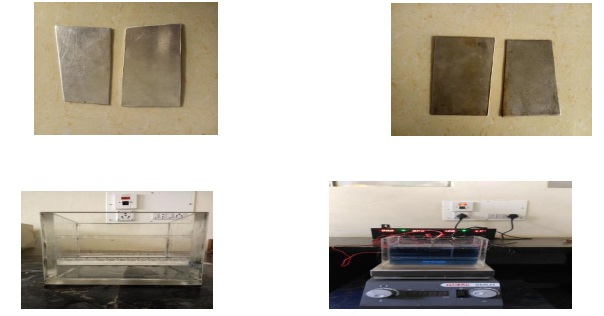

Wastewater (supernatant) after coagulation (first stage of treatment) of the optimum dosage of coagulant cactus obtained is poured into electrochemical cell. Electro-coagulation is conducted in a 1500ml capacity of electrochemical cell. Aluminium and stainless steel electrodes are used for this treatment. The electrodes are fixed parallel with each other. The gap between each electrode will be kept at minimum distance depending upon the overload of current. The depth of electrodes are immersed in the electrolytic solution at 80mm. Each electrode are connected to regulated DC power supply (220V). The magnetic stirrer is used in electrochemical cell to maintain a homogenous composition.

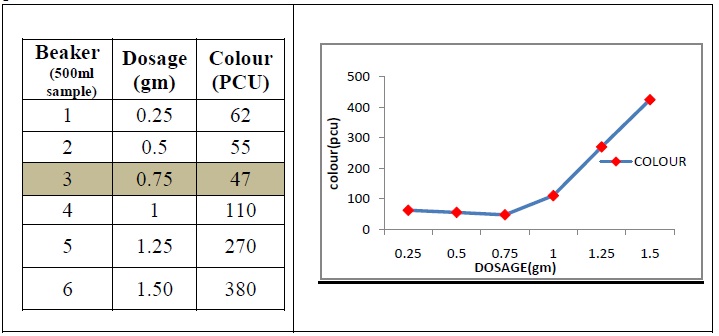

For further treatment of textile wastewater, adsorption experiments with the Eucalyptus bark powder as a low-cost adsorbent is carried out in 1L flasks. Each test consists of 500mL of supernatant(after electrocoagulation) with a desired initial concentration of adsorbent without pH adjustment and it is transferred into the beaker on the magnetic stirrer. Different doses of eucalyptus bark powder is added to the wastewater sample, and the obtained suspension is immediately stirred for 60 min(shaking speed 150rpm). After the desired contact time, the samples are withdrawn from mixture using a micropipette and is analyzed for the determination of the final concentration of dye at a wavelength of 525mm and also other mentioned parameters.

Cactus (opuntia) was investigated on its potential to remove turbidity from textile wastewater. The limit of using cactus in wastewater treatment is related to the variability of efficiencies of cactus preparations, which depends on wastewater characteristics. 2gms of cactus (opuntia) showed the optimum turbidity removal result ( 56% removal) to treat 1 litre of effluent. Being bio-degradable, eco-friendly, abundant ,inexpensive and safe to human health ,cactus (opuntia ) is a promising alternative to the conventional coagulants used in the treatment of textile wastewater.

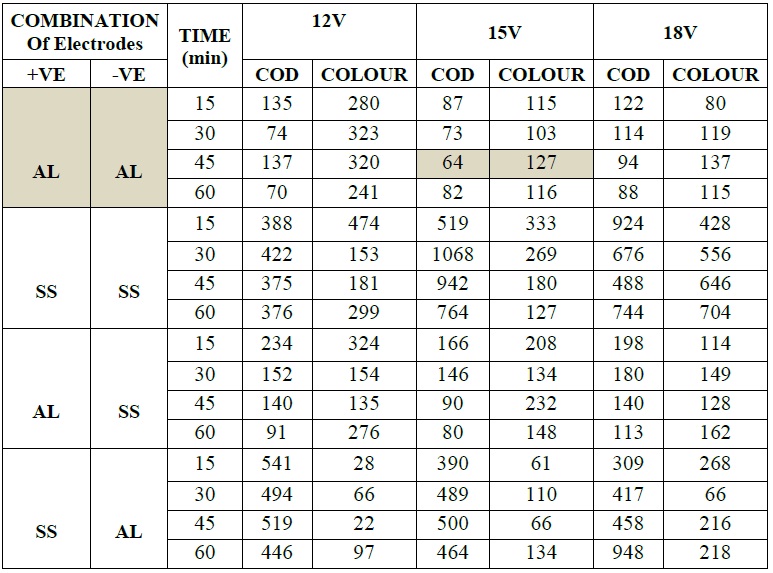

To investigate the effect of electrode connection, colour and COD removal efficiency were analyzed in electro coagulation treatment for different time interval and voltage variation for 4 different electrode connections Al-Al, SS-SS, Al- SS, SS-Al. The results after electro coagulation treatment of textile wastewater showed that COD and colour can be easily removed using this technique. From this experimental study , Al-Al combination was found efficient for textile industry wastewater treatment at 15v and contact time of 45min, the gap between the electrode was 6cm, the COD and colour was degraded from initial concentration of 684 mg/l and 510 PCU to 64 mg/l and 127 PCU

The Eucalyptus bark powder could be used effectively for the removal of colour from textile wastewater. The amount of colour adsorbed per unit mass of eucalyptus bark powder was found to increase with increase in adsorbent dosage. The maximum % removal of colour in this study achieved is 63% for the dosage of 0.75g per 500ml wastewater. Since eucalyptus bark powder is cheap and the availability is not restricted, it can be effectively used as adsorbent in the wastewater treatment.

It can be concluded that cactus (opuntia) powder, aluminium electrodes and eucalyptus bark powder has the potential to be utilized for textile wastewater treatment applications effectively in removing colour, turbidity and COD.

The present study were focused on the colour removal from textile wastewater at triple stage treatment at various dosage of coagulants, adsorbent and different combinations of electrode. Some other parameters like pH and temperature are also recommended

Based on the present experimental work and gained experience, the following suggestions are being made for future research work.

1. Electro coagulation may be worked with varying electrical conductivity and pH with different electrode connections

2. The electrode can clubbed with other electrodes in series or parallel connections

3. The adsorption technique can be carried out with different dosage of adsorbent with different contact time

4. This triple stage treatment technique could be carried with continuous mode with varying flow rate at different reactor volumes

1. A. Babuponnusami,S.Velmurugan,(2017)."Investigation on adsorption of dye (reactive red 35)on egg shell powder”, International Journal of Chem Tech Research,Vol.10,pp.565-572.

2. A. EL-MAGHRABY,H.A.EL DEEB,(2011).”Removal of a basic dye from aqueous solution by adsorption using rice hulls”,Global NEST Journal,Vol 13,No 1,pg.no.90-96.

3. A Latha,PPartheeban, R Ganesan,(2017).”Treatment of textile wastewater by electrochemical method”, International Journal of Earth Sciences and Engineering,ISSN 0974-5904,Volume 10,No.01.

4. Akanksha,RoopashreeG.B,Lokesh K.S,(2013).”Comparative study of electrode material (iron,aluminium and stainless steel )for treatment of textile industry waste water”,International Journal of Environmental Sciences,Volume 4 ,No 4.ISSN 0976-4402.