Published on Nov 30, 2023

Concrete is the most widely used construction material composed of cement, fine aggregates, coarse aggregate and water, which can be moulded into different shapes and hardened with time to give a solid mass.

This concrete has three phases for analysis as aggregate phase, paste phase and transition phase. Out of the three phases transition phase is the weakest which is mainly influenced by bonding of aggregate and paste. Upon application of the load, the cracks which are inherently present in the transition phase starts propagating causing the failure of the element. This is poor transition phase and movement of inherent cracks makes the concrete poor in tension.

In case of structural concrete, there are different zone based on the stress which causes the failure of the concrete.

The structural concrete not only faces compression load but also are subjected to various loads, effects like torsion, bending, buckling, etc. All these load effect causes the tensile stress and compression stresses in the concrete. As the concrete is weak in tension, to overcome the weakness of concrete in tension, reinforcement bars are provided in the concrete and this technique is called as Reinforced Cement Concrete (RCC). In RCC the concrete and steel reinforcement work in composite action.

Keywords : Neutral axis, Shredded rubber, Tension and Compression, Low grade concrete, Partial beam.

As the concrete is weak in tension, reinforcement is provided at the bottom portion of beam section. As the compressive loads are induced in the zone above the neutral axis compressive strength of concrete lying above the neutral axis is very important parameter this induces compressive stresses in the top zone above the neutral axis.

When a beam is subjected to bending the layers below neutral axis will be under tension and the layers above neutral axis will be under compression, hence the full strength of concrete is not utilized below neutral axis. In the proposed project work the behaviour of beams are studied by replacing the grade of concrete near neutral axis and performing flexural test on beams. The results of the specimens modeled are compared with regular beams and the variations are analyzed.

On this basic idea which led to the concrete grade reduction in tension zone for RCC beams to reduce the construction cost. Hence in this project we are reducing the grade of concrete below the neutral axis in order to check the flexural behavior. The strength of concrete is reduced below the neutral axis by replacing regular fine aggregates (sand) by shredded rubber.

When a beam is subjected to bending, the layers below neutral axis will be under tension and the layers above neutral axis will be under compression, hence the full strength of concrete is not utilized at neutral axis. In the proposed project work, the behaviour of beams is studied by replacing the grade of concrete near neutral axis and performing flexural test on beams. The results of the specimens modeled are compared with regular beams and the variations are analyzed.

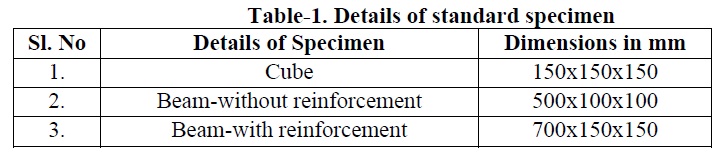

The materials used in the work are cement, coarse aggregate (jelly), fine aggregate (sand), shredded rubber and steel.

Specific gravity test using Le-chatelier’s apparatus , normal consistency test, initial and final setting time test for the cement were conducted.

Specific gravity test using pycnometer and sieve analysis were the tests conducted for the fine aggregates.

Specific gravity test using pycnometer was conducted for the coarse aggregate.

With the concept of minimum reinforcement for the beam i.e 0.2%bD the steel was procured from the local vendor. Main reinforcement of 10mm diameter and Stirrups of 8mm diameter were provided. The minimum spacing of 150mm is provided. The stirrup is provided with the hook of 90 degree bend.

Mix design is done according to IS 10262: 2009

Cement – 437.78 Kg/m3

Fine Aggregate – 627.42 Kg/m3

Coarse Aggregate – 1156 Kg/m3

Water - 197Litres/m3

For partial beam, sand is completely replaced with the shredded rubber and the proportion is 400kg/m3

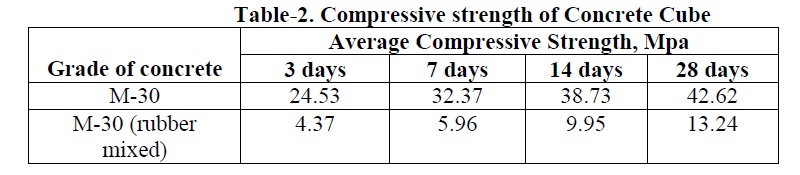

The specimens were removed from curing tank and its surfaces are cleaned with cotton waste, they were tested in a 3000kN compression testing machine. The rate of loading was maintained at 140/kg/cm2/min.

Reference code: (IS: 516-1969).

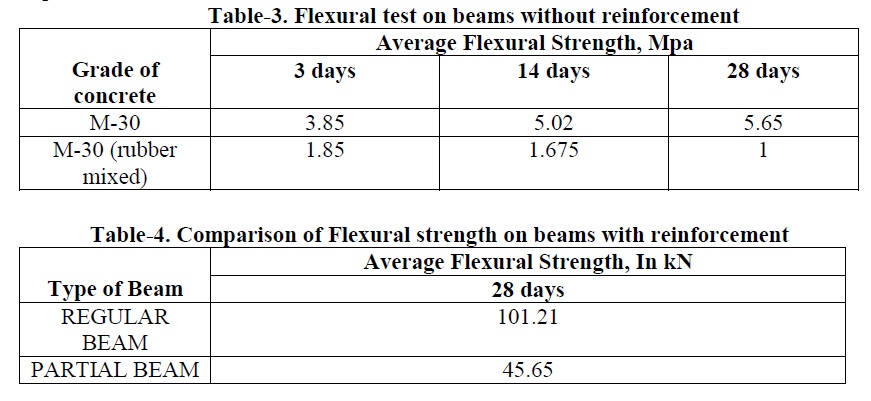

Specimens were removed from the curing tank and its surfaces were cleansed with cotton waste and were let to dry. They were tested with Two-point loading setup. The rate of loading was maintained at 7kg/cm2/min. on hardened concrete strength related test such as compression test and flexural test were conducted for curing periods for 7,14 and 28 days in accordance with BIS specifications and the results are listed in tables.

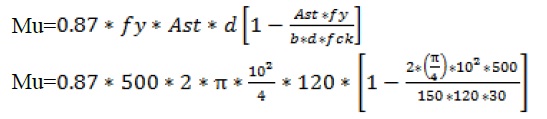

Mu= 7.01 KN-m

From Table-3 it can be observed that the Flexural strength of partial beam is less compared to the Flexural strength of Regular Beam. Hence the objective to use the lower grade of concrete below neutral axis is achieved.

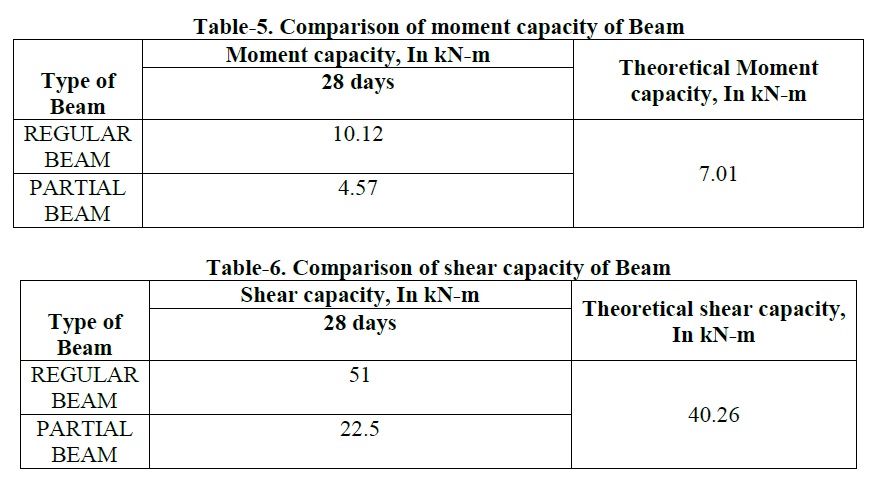

The comparison between theoretical value of moment as per Indian Standards and experimental moment value is tabulated as shown in Table- 5.

The Experimental results shows higher value than theoretical value in case of Regular beam. But in case of Partial beams the Experimental results are lesser compared to theoretical observations.

The capacity of shear is 40.26kN, but shear force is more than the capacity. Hence it failed in shear.

From the above results, we observed that the beams have failed in shear. And the failure is during the stress transfer in neutral axis. Hence the project may be further studied by replacing the pipes with mesh and analyze the results.