Published on Nov 30, 2023

It is well known that when soil is compacted using external energy, the density of soil reaches maximum value at a moisture content known as the (OMC).

The value of OMC and MDD depend on the energy input during the compaction, also the compressive strength of the soil depends the dry state of the soil. Thus, the process of mechanical compaction can lead to densification and strengthening of soil.

If the soil is to be stabilized against loss of strength during saturation, we can think of a stabilized mud block where the stabilization is achieved by a combination of densification and mixing of a stabilizing additive (cement, lime and bitumen).

Coconut fibers are obtained from the fibrous husk (mesocarp), it has high lignin content and thus low cellulose content, as a result of which it is resilient, strong and highly durable.

The lightness of the fibers is due to cavities arising from dried out sieve cells.

Usage of coconut fibers can resist fungi and rot, provide excellent insulation against temperature and sound, unaffected by moisture and dampness, tough and durable.

Keywords : Optimum Moisture Content (OMC), Maximum Dry Density (MDD), lignin.

Energy efficient- 70% savings when compared to burnt bricks.

Economical (20-40% when compared to brick masonry).

Plastering of walls can be eliminated.

Better block finish.

Aesthetically pleasing.

Usage of waste fibers from industries which is obtained as byproduct.

The coconut fiber was obtained from vendor market.

The coconut coir was treated with sodium hydroxide as the first treatment and potassium permanganate as second treatment also the fibers are soaked in water as third treatment and at every treatment it is oven dried at 90ͦ C for 5hrs.

Soil is sieved and passed through 75 micron.

The coconut fiber was grated to smaller form, then mixed with equal amount of the soil at four (4) different mix ratio by percentage weight of 100%:1%, 100%:2%, 100%:3% and 100%:4% respectively of soil and grated coconut fiber.

10% of flyash by weight of soil is added.

Water was sprinkled on the stabilized soil while it is being mixed by hand until it form a firm lump when squeezed in the hand and just enough moisture appeared on the surface to give a shiny appearance. Casting fiber reinforced SSM blocks of standard size 23cmx10.8cmx10cm

Cast FRSSM blocks are covered by gunny bag and kept under shade, water content/moisture content is maintained by sprinkling water frequently.

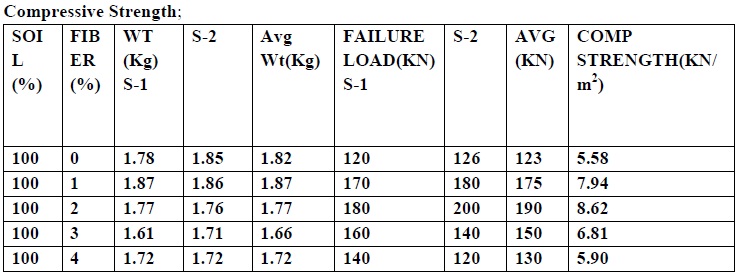

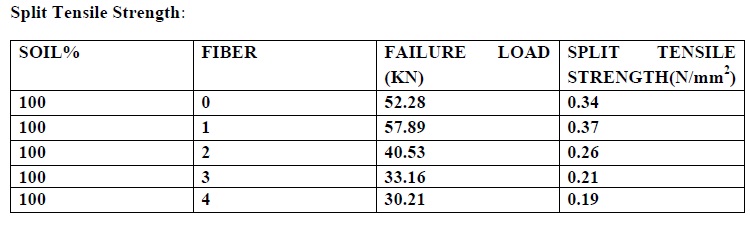

The cured FRSSM blocks are subjected to compressive strength, water absorption test, split tensile strength.

Use of coir fibre gives natural cooling effect.

Coconut waste is more efficient than normal blocks.

The compressive strength is found to be 8.22 KN/m2 which is greater than normal SMB.

The tensile strength is found to be 0.37 N/mm2 which is greater than conventional blocks.

In case of coconut waste, the shorter fibre gives good result as compared to longer fibre.

Use of jute fibers instead of coir fibers.

Finding compressive and tensile strength of jute fibers.

Comparing with conventional blocks and reporting the results.

Comparison of tensile and compressive strength between jute and coconut coir.

Finding tensile and compressive strength using both coconut and jute fibers.