Published on Apr 02, 2024

A colloid is a mixture in which one substance of microscopically dispersed insoluble particles is suspended throughout another substance. Owing to this peculiar structure of colloid, it has varied physical and chemical properties. Let us explore more about the physical, chemical, optical as well as electrical properties of colloidal solutions.

Colloids exhibit a phenomenon known as the Tyndall effect observed by Tyndall in 1869. When we pass an intense converging beam of light through a colloidal solution kept in dark, the path of the beam gets illuminated with a bluish light. This phenomenon of scattering of light by colloidal particles is called Tyndall effect and the illuminated path is known as Tyndall cone. The dispersed colloidal particles scatter the light falling on them resulting in emissions that are comparable to ultraviolet and visible radiations. These scattered radiations get illuminated.

The size of the particles which form homogenous or true solution is less than 10-7 cm while the size of particles which form heterogeneous solution is greater than 10-4 cm. The intermediate state between these two is called Colloidal State of matter.

It is also called hydrophobic sol (if water is used as medium). It is the suspension of hydrophobic (a water repelling) substance, which contains non-polar groups in water. This includes dispersal of oil, fats, metal oxide, hydroxide, sulphide, etc, in water. These sols are quite unstable & require a small amount of electrolyte (stabilizer) for their stabilization.

It is also called hydrophilic sol (if water is used as medium). It is the suspension of hydrophilic (water loving) substance which contains polar groups in water. For example, substances like gum, albumin, gelatine, etc. These sols are quite stable i.e. require no stabilizer.

Lyophilic sols may be prepared by simply warming the solid with liquid dispersion medium. E.g. Gum with water. On the other hand, lyophobic sols have to be prepared by special methods. These methods fall into two categories;

1. Condensation or Aggregation Methods.

2. Dispersion Methods.

These methods consists of chemical reactions or change of solvent whereby the atoms or molecules of the dispersed phase appearing first, aggregate to form colloidal particles. The conditions (temp., conc. etc) used are such as permit the formation of sol particles but prevent the particles becoming too large and forming precipitate.

The important chemical methods for preparing lyophobic sols are as follows;

An Arsenic Sulphide (AS2S3) sol is prepared by passing a slow stream of hydrogen sulphide gas through cold solution of arsenious oxide (AS2O3). This is continued till a yellow colour of sol attains maximum intensity.

AS2O3 + 3 H2S-------->AS2S3 (Yellow Sol) + 3H2O

Sols of silver halide are obtained by mixing dilute solutions of silver salts and alkali halides in equivalent amounts. Silica gel sol is prepared by this method between dilute solutions of sodium silicate and HCl.

A Colloidal sol of sulphur can be obtained by passing hydrogen Sulphide into solution of sulphur dioxide in water or through a solution of an oxidising agent (Bromine water, nitric acid).

SO2 +2H2S-------->3S+2H2O

H2S + (O)-------->S + H2O

A colloidal solution of a metal like silver, gold and platinum can be prepared by reducing their salt solutions with suitable reducing agents, such as stannous chloride, formaldehyde, hydrazine, tannic acid etc.

2AuCl3 + 3SnCl2--------> 2Au (Gold sol.) + 3 SnCl4

or AuCl3 + Tannic acid-------->Au (Sol.)

The method is used to prepare hydroxides and oxides of weakly electropositive metals like Fe, Al or Sn. A red sol of ferric hydroxide, is obtained by adding few drops of 30% ferric chloride solution to a large volume of almost boiling water and stirred with a glass rod.FeCl3 +3H2O-------->Fe(OH)3 (Red Sol.) + 3HCl.

The important physical methods for preparing lyophobic sols are:

When a true solution is mixed with an excess of the other solvent in which the solute is insoluble but solvent is soluble, a colloidal solution is obtained. For Example, when a solution of sulphur in alcohol (ethanol) is added to an excess of water, a colloidal solution of sulphur is obtained due to decrease in solubility.

The colloidal solution of ice in an organic solvent such as CHCl3 or ether can be obtained by freezing a solution of water in the solvent. The molecules of water which can no longer be held in solution separately combines to form particles of colloidal size.

In this method large particles of the substances are broken, into particles of colloidal dimensions in presence of dispersion medium. Since the sols formed are highly unstable. They are stabilized by adding some suitable stabilizer. Some of the methods employed for carrying out dispersion are as follows:

In this method, the coarse particles along with dispersion medium is brought into colloidal state by grinding it in colloidal mill, ball mill or ultrasonic disintegrator. The solid particles along the dispersion medium are fed into the colloidal mill. The mill consists of two steel plates nearly touching each other and rotating in opposite directions with high speed (7000 rev/min). The solid particles are torn off to colloidal size and are then dispersed in liquid to give the sol colloidal graphite (lubricant) and printing inks are made by this method. Recently, a mercury sol has been prepared by disintegrating a layer of mercury into sol particles in water, by means of ultrasonic vibrator

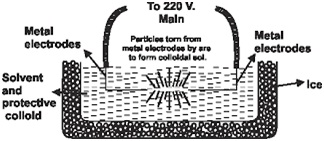

This process involves dispersion as well as aggregation. Colloidal solutions of metals such as gold, silver, platinum etc. can be prepared by this method. In this method electric arc is struck between electrodes of metal immersed in the dispersion medium. The intense heat produced vapourises some of metal, which then condenses to form particles of colloidal size.

Peptisation may be defined as the process of converting a precipitate into colloidal form by shaking it with dispersion medium in the presence of small amount of electrolyte. The electrolyte used for this purpose is called Peptizing Agent. This method is applied, generally, to convert fresh precipitate into colloidal solution because such precipitates are simply clusters of particles of colloidal size held by weak forces.

During peptisation, the precipitate adsorbs one of the ion of the electrolyte on its surface. The adsorbed ion is generally common with those of the precipitate. This causes the development of positive or negative charge on precipitates which ultimately breaks up into smaller particles having the dimensions of colloids. For example: When freshly precipitated Fe(OH)3 is shaken with aqueous solution of FeCl3 (Peptising agent) it adsorbs Fe3+ ions and thereby breaks up into small sized particles of type Fe(OH)3 / Fe3+. Similarly a precipitate of AgCl on shaking with dilute solution of AgNO3, adsorbs Ag+ ion and gets peptised to colloidal particles of type AgCl / Ag+. In some cases, peptisation can also be achieved by organic solvents. For example: Cellulose nitrate is peptised by ethanol. The colloidal solution so obtained is known as Colloidion.

Two beakers of 250 ML & 50 ML, Funnel, glass rod, tripod-stand, wire gauze, burner, filter papers, distilled water (100 ML), Arabic gum 4.5 g

Gums are naturally occurring complex polysaccharides. Gum is secreted by stems of trees to seal wounds in the bark. All gums are soluble in water. Gums on heating with water get hydrolysed to yield a number of monosaccharides which are smaller in size. Thus, a colloidal sol is obtained.

a. Take 4-5 g of dry Arabic gum in a mortar and grind it with the help of pestle.

b. Transfer gum powder in a 250 ML beaker, add 100 ML distilled water and heat the mixture up to 600C with constant stirring for 4-5 minutes.

c. Stop heating, allow the solution to cool up to room temperature and filter it.

d. The filtrate obtained is the required sol.

a. Mortar, pestle, beakers, glass rod should be properly cleaned.

b. Stirring should be done constantly during addition of gum powder to hot water.

c. Distilled water must be used for preparation of sol.

(i) It is used in pharmaceuticals as a demuicent.

(ii) It is used topically for healing wounds.

(i) Ingestion of Arabic gum sol may raise serum cholesterol.

(ii) Allergic reactions to Arabic gum sol may cause respiratory problems.

• htpp://www.icbse.com/

• http://www.sciencedaily.com/

• http://www.digg.com/