Published on Nov 30, 2023

The objective of this work was to study bio-oil production from sugar cane trash by a pyrolysis process in fluidized bed reactor. The experiments were carried out at different temperatures ranging from 460 – 540 oC and at different medium gas flow rates between 120 -160 cc.s-1. Two different gases, Nitrogen (N2) and air, were used as the fluidizing medium in order to study the effect of a different medium on the yield and properties of the bio-oil. The experimental result showed that the maximum bio-oil yields of 46.2 wt% and 31.95 wt% were obtained at 500 oC and 160 cc.s-1 for air and Nitrogen medium, respectively. The bio-oil yield obtained when using air as a medium was higher than that when using Nitrogen medium. This was a result of the higher quantity of water content in the air. The properties of bio-oil were determined and the result showed that its heating value, dynamic viscosity, density, water content, and pH were 15.48 MJ.kg-1, 2.31 cSt 1,019 kg.m-3, 52 wt% and 3, respectively. By dehydration of the obtained bio-oil, the heating value, viscosity and density were increased to 19.81 MJ.kg-1, 57.66 cSt and 1,260 kg.m-3, respectively.

These results show that the bio-oil can be used as a fuel oil for combustion in a boiler or a furnace without any modification. Furthermore, the energy consumption of the pyrolysis process was analyzed.

One day our sources for traditional sources including petroleum would be depleted. Bagasse is most promising eco friendly alternative source of renewable energy source as a industrial residues in the context of current energy scenarios. And it is cheap, abundantly available and does not require significant effort to collect. It has additional benefits in terms of transportation because it can be utilized on the spot after sugar crushing.

Although now a days the industries are using sugar cane bagasse for many applications such as production of pulp, boards and paper products, and civil works. But most large and medium sized mills can use up to 75% of bagasse to generate heat and electricity so the remaining 25% of bagasse is going waste therefore we planning to utilize that to produce alternative fuel.

Since our college is surrounded with 10-15 sugar industries within the vicinity of 25 km. Therefore we have elected to work on it as a project work. Initially we had studied the problems of sugar industries and majorly we found that tons of bagasse is wasting as a by product, and bagasse is mainly containing 80% - 90% of volatile matter which is more advantage in case of pyrolysis process. Hence we are going to concentrate on conversion of bagasse into useful liquid fuel by pyrolysis method.

Our current investigation is to convert the waste bagasse into useful liquid fuel by pyrolysis process. In present scenario the population in India is increasing so that the demand for energy also increasing exponentially. The people are looking towards the fuels like petrol, diesel and kerosene etc. Therefore through this project we are seeking towards alternative fuel (bio-oil) for clean, domestic and renewable energy which is commonly accepted as the key for the future, not only for India and also for the world.

For the improvement of maximum energy from particular biomass, the technically and economically viable process should be selected. the pyrolysis and gasification are the current techniques for the renovation of biomass into bio oil or gaseous fuels before burning it. but the problem of gasification is the obscurity of storage, transportation and handling of gaseous fuels. In case of pyrolysis of biomass the liquid products have advantages in transport, storage, combustion, retrofitting and flexibility in production and marketing and even bio liquid is safe product than the gaseous product. thus the bio oil is identified and presented as a bio fuel applicant. it has numerous socio-economic advantages as well as it is one efficient conversion way compared to other thermo-chemical conversion technologies.

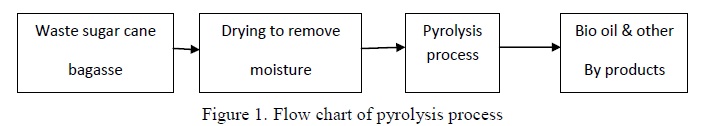

Pyrolysis has been receiving more awareness as an capable method in converting biomass into bio fuel. the pyrolysis is carrying out at the temperature between 350-750 0c. and flow chart of this pyrolysis process is illustrated as below figure 1.

We had conducted the experiment with 3kg of bagasse, initially at 800 C the non-condensable gases were liberating through outlet and we got bio-oil which is having moisture at 1000C . In between the temperature range of 160-1900C we got bio-oil of having less moisture content, we reached the temperature range upto 450-5000C .

The waste bagasse can be utilized for producing energy or else it may lead to many issues like space management, disposal, transportation, dust etc. Therefore if we utilize it to produce an alternative source of energy, we can survive for the future days and pollution is the most causing effect for health imbalance of human as well as animals and birds in today’s environmental conditions, but this bio-oil decreases the pollutants which are destroying the environment, hence it can be used as a socio-economic fuel.

S.Czernik and A.V.Bridgwater ( Applications of biomass fast pyrolysis oil)

Ugur Morali, Sevgi Sensoz (Characterization of bio-oil and bio-char)

Beeharry (Availability and moisture content of different bio-masses)

Garcia-Perez (Study of density content)

The non-condensable gases which are producing in this process can be utilized directly for the gas turbines as a fuel.

Instead of waste sugar cane bagasse, we can use other wastes like muncipal waste, waste trees’ leaves etc.

Bio-oil production from sugar cane trash by a pyrolysis process was conducted in a fluidized bed reactor. The effects of the pyrolysis temperature, flow rate, different fluidizing medium on the yield of bio-oil production were investigated. The properties of the bio-oil and the energy consumption were also studied. The experiments were performed by varying the temperature from 460 ºC – 540 ºC and at flow rates of 120 cc.s-1, 160 cc.s-1 and 200 cc.s-1 under air and N2 atmosphere. From the experiment, sugar cane trash can be pyrolyzed into bio-oil. The experimental result showed that the maximum yields of bio-oil were 46.2 wt% and 31.95 wt% obtained at 500 ºC and 160 cc.s-1for air and N2 medium, respectively. The bio-oil yield obtained from using air as a medium was higher than that when using N2 as a medium because of the presence of water content in the air. The result also revealed that the yield of bio-oil varied with the combustion temperature and volumetric flow-rate of the fluidizing medium.

[1] NEPO (National Energy Policy Office) Journal Volume 50 [online] 2000 [cited 2009 Dec. 7]. Available from : http://www.eppo.go.th/vrs/VRS50-03- FutureFuel.html

[2] M. Asadullah, M.A. Rahman, M.M. Ali, M.A. Motin, M.B. Sultan, M.R. Alam and M.S. Rahman, Jute stick pyrolysis for bio-oil production in fluidized bed reactor, Bioresource Technology 99, 2008, pp. 44-50.

[3] Z. Ji-lu, Y. Wei-ming and W. Na-na, Bio-oil production from cotton stalk, Energy Conversion and Management 49, 2008, pp.1724–1730.

[4] S. Wang, M. Fang, C. Yu, Z. Luo and K. Cen, Flash Pyrolysis of biomass particles in fluidized bed for bio-oil production, China Particuology 3 (1-2), 2005, pp.136 – 140.