Published on Nov 30, 2023

Prosthetics is an artificially made substitute for a limb lost through a congenital defect (present at birth), accident, illness, or wartime injury. the last two decades, there have been great strides in the development of novel prosthetic hands and terminal devices that take advantage of the latest technological advances, moving toward more advanced bionic hands, however it leads higher in cost. This higher end prosthetic cannot be affordable by a common people as its difficulty in maintenance. These limitations leads a research on the mechanical hand which would give better movement and affordable. The Current existing mechanical hands have limited functionality or it is made only as aesthetic. Hence this project is a focus on mechanical prosthetic which operated by physical strength of person so that all sensors and motors are eliminated. Current prosthetic hand has least degrees of freedom and it does not contain wrist movement hence it becomes less flexible for the person. This project gives multi functional like finger movement, wrist movement, and arm movement.

Hence person can do his least daily needs and become self dependent. This hand is made with equal weight of other hand to make body balance. These hand uses aluminum and mild steel material for its parts construction. The movement can be achieved by stretching the cable which is connected to chest belt, which wore by disabled persons.

Recent improvements in body armor, battlefield medicine, speed of evacuation, and surgical techniques have resulted in a high incidence of survival from blast wounds sustained during armed conflict (Figure 23-1). The mechanisms of injury include explosively formed projectiles, improvised explosive devices (IEDs), mobile IEDs, rocket-propelled grenades, suicide vehicleborne IEDs, and gunshot wounds. Those individuals who survive are frequently polytraumatized and challenged with hearing or vision impairment, burns, traumatic brain injury (TBI), upper and lower extremity injuries, and/or amputations. Service members with well-irrigated, but open, wounds are rapidly transferred from the battlefield to a rehabilitation hospital, which requires an organized approach to prosthetic rehabilitation.

To enable a young and motivated amputee population to return to highly active military and civilian lifestyles, the military healthcare system has implemented a comprehensive, multidisciplinary model of rehabilitative care. The entire rehabilitation process is accelerated because of the superior premorbid physical status and goal-oriented mindset of the service member, both of which have been fostered in the military environment. Wounded service members approach rehabilitation with focused determination to reach the initial goal of returning to active duty or reintegrating into civilian life. They place high expectations on themselves and on the care they receive. Prosthetic rehabilitation for these individuals is also complemented by their previous training in the manipulation of external devices, including weaponry and computer systems, as well as the excellent hand-eye coordination developed through military training, recreational pursuits, and electronic gaming

The main aim of this project is to overcome the handicapped situation and to make a person Self-dependent. In this work the objective is to achieve the prosthetics for upper limb with low cost so that it can be affordable by common people. This work aims to have the movements of finger, wrist and arm. This prosthetics hand is to be operated by means of spring action through the cable. And also the objective is to avoid the sensors and motors for the operation so that the handicapped person free from frequent maintenance and carrying the battery.

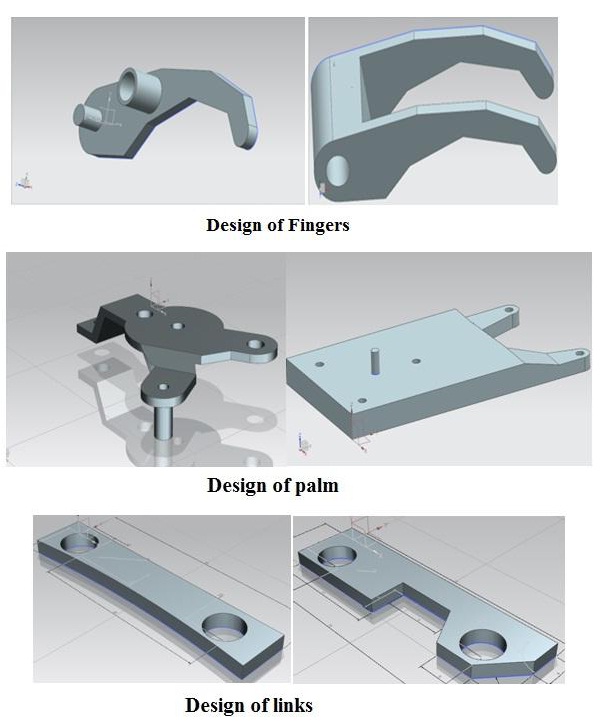

To Develope this low cost mechanically operated prosthetic requires the appropriate study of the past prosthetic and the present prosthetic hand. The study revealed that there was no appropriate wrist movement in the simple prosthetic hand whereas the presence of the wrist movement in bionic hand makes it more expenses. Taking all these into account, appropriate design and dimensions of the various parts like fingers, links, palms, etc have been done to the requirement. The aluminum material is used to develop the fingers, palm and links which connects all parts of hand.

The above components are assembled together to obtain the proper structure of the required prosthetic. The fingers, shaft, and palm dimensions are taken according to the literature survey and it is drawn in the UG-NX software. The different parts have to be done according to required dimension given in the drawing. The fingers are made to connect with the shaft and the finger movement is obtained by using specific extension spring. The finger and arm movement are obtained by using the cables which are connected to the chest belt of the person.

The cable length can be varied by stretching the chest of a person who fitted with this prosthetics. When the cable stretches out, the fingers are made to move outward and things can be picked up. The wrist movement is achieved by folding the arm towards the personthis assembly is mounted on the base plate which is of mild steel to have enough strength on the wrist movement. This plate is connected to the other plate which bridges the cap between the upper fist and the forearm. The forearm is structured with wood and it turned to make it taper. Again by using spring which is connected between the two plates which enables the wrist movement of appropriate angle. The strip is passed in such a way that when the motion is given to the arm, the tension is produced in the spring, thereby providing the wrist movement.

The result of this fabrication process is that, the cost of this prosthetic hand is less compared to that of bionic hand and it is more flexible and reliable since it contains wrist movement. Since no battery or motors are used the maintenance is easy and costs less.

Prosthetics is an artificial device that replaces the missing body part, which may be lost through trauma diseases or congenital condition, so to overcome such problems prosthetic limbs came into use to make an individual self-dependent.Despite many advances of bionic hand, mechanical operated prosthetic will have ease in construction and also will have less maintenance charges. As we know that advanced and highly technical and well versed bionic hand are available, but the current cost and maintenance almost make it impossible for common man to afford.

So the prosthetic operated by simple mechanism might have great scope, since it is simple in construction and easily affordable for common people. On the basis of operative mechanism point of view it becomes great medium for normal people.In this project, the arm can be made by using plastic/fiber materials so that it can be light weight can improve the aesthetics looks. The movement of wrist can be operated by dc-motors, with pulling arrangement so that the physical stress on the person can be avoided but once again it leads higher cost and also person should knowledge to operate it.

Prosthetics is a tool to lead life for the person who lost their hands/legs through congenital defect develops more advanced prosthetics but the main concern is the cost. If the cost is less, then it will be affordable for middle class/ common people so they can work independently. Hence the main aim is developing prosthetics with minimum cost.

As for arm prosthetics, the extent of work can be performed by prosthetics largely depends on the interaction of physicians, surgeons, prosthetics and engineers if meaning full multi-functional control prosthetics are developed then surgeons and physicians need to perform innovative procedure during medical treatment for the patients.In this project, a mechanical hand physically operated prosthetics is developed which leads less maintenance and repairing cost.As compare to bionic or motorized prosthetics the Bionic hand is costlier as it contains sensors and precision motors for its operations and its maintenance may take long process which makes the patient inconvenience due to lack of prosthetics during repairing works.

Hence this project is adoptable for common people who lost their hand and repairable at lower cost. This project is simple in design and operated mechanically by physical strength of disabled person. By stretching his/her chest the finger movement can be performed and can hold the items as His/her wish. The wrist movement is achieved by holding his/her arm towards is body so that he can fill the object according to arm folding angle, which gives great advantages to the disabled person.

1. Winter DA. Biomechanics of Human Movement. New York: John Wiley and Sons, Inc; 1979.

2. Dillingham TR. Rehabilitation of the upper limb amputee. In: Dillingham TR, Praxedes VB, eds. Rehabilitation of the Injured Combatant. Vol 1. Textbook of Military Medicine. Washington, DC: Department of the Army, Office of The Surgeon General, Borden Institute; 1998: 65.

3. Scott RN. Feedback in myoelectric prostheses. Clin Orthop Relat Res. 1990;256:58–63.

4. Scott RN. Myoelectric control systems research at the Bio-Engineering Institute, University of New Brunswick. Med Prog Technol. 1990;16:5–10.