Published on Nov 30, 2023

From earlier times, the art of artificial cooling is employed in the preservation of the perishables such as milk, food, drinks, medicines, etc. Indoor air cooling has also been employed in order to provide humanitarian comfort and cool environment in industry applications. The application of cooling is employed in various fields. The two methods employed for artificial cooling are refrigeration and air conditioning. Since refrigerators and air conditioners are widely used, these systems have to be manufactured economically and ensure that they are energy efficient.

The air conditioning system is designed to provide a comfortable living or workingenvironment within a specific area by controlling the surrounding at a suitable range oftemperature, relative humidity, air circulation and purity of the air. The air conditioners are generally used in residential and commercial buildings. Along with air conditioners the electric water heaters and water coolers have also been used in residential buildings. The usage of these electric appliances has been increasing day by day in most part of the world. Due to this, the consumption of energy has increased. Energy saving is one of the key issues not only from the view of energy conservation but also for the support for the global environment.

Therefore, more efficient devices have to be designed which reduces the energy consumption and the cost. The cost can be minimised if different devices working in same principle are integrated into single device. The air conditioner can be integrated with the water heater and water cooler. These devices work on the similar principle. The water cooler and air conditioner work in vapour compression cycle and the water can be heated in the condenser. Thus, by integrating these three devices the purchase cost is reduced since these devices will work on single common compressor. The advantage of this system is that the water is heated from the heat released by condenser. The condenser of conventional water cooler are air cooled, due to which the heat energy gets wasted. This energy is utilised to heat the water and energy is conserved. This system is multifunctional used to perform three operations reducing the cost and energy consumption.

Any substance capable of absorbing heat from another required substance can be used as refrigerant i.e. ice, water, air or brine. A mechanical refrigerant is a refrigerant which will absorb the heat from the source and dissipate the same to the sink or in the form of latent heat. The physical properties will enable them to repeat continuously a liquid to gas and gas to liquid transformation. Air was used as a refrigerant in many refrigerant system in olden days considering as safest refrigerant. Ammonia, carbon dioxide and sulphur dioxide were used for domestic and commercial purposes until ferons were available. The refrigerants are classified in to two groups:

1. Primary refrigerants

2. Secondary refrigerants Primary refrigerants directly take the part in the refrigerants system where secondary refrigerants are first cooled with the help of the primary refrigerants and are further used for cooling purpose.

The air conditioning system is designed to provide a comfortable living or workingenvironment within a specific area by controlling the surrounding at a suitable range oftemperature, relative humidity, air circulation and purity of the air. The air conditioners are generally used in residential and commercial buildings. Along with air conditioners the electric water heaters and water coolers have also been used in residential buildings. The usage of these electric appliances has been increasing day by day in most part of the world. Due to this, the consumption of energy has increased. Energy saving is one of the key issues not only from the view of energy conservation but also for the support for the global environment.

Therefore, more efficient devices have to be designed which reduces the energy consumption and the cost. The cost can be minimised if different devices working in same principle are integrated into single device. The air conditioner can be integrated with the water heater and water cooler. These devices work on the similar principle. The water cooler and air conditioner work in vapour compression cycle and the water can be heated in the condenser. Thus, by integrating these three devices the purchase cost is reduced since these devices will work on single common compressor. The advantage of this system is that the water is heated from the heat released by condenser. The condenser of conventional water cooler are air cooled, due to which the heat energy gets wasted. This energy is utilised to heat the water and energy is conserved. This system is multifunctional used to perform three operations reducing the cost and energy consumption.

The frame structure is used to support the entire system. It acts as base for the system. Frame makes the system portable by using heavy duty wheels. The material used for frame work is galvanised iron pipe of size 1inch×1 inch. The dimension of the frame is Length - 4 ft, Width- 2.5 ft, Height- 2.5 ft, Number of wheels used -4 A plywood of dimension 4×2.5 ft is used to mount the system on the frame.

The suction and discharge pipes of compressor are joined with the tee fitting to obtain two flow lines. The two lines of suction are joined with evaporator coils of both air conditioner and water cooler. Similarly, the discharge lines are attached to the condenser coils. The condenser coils in water cycle serves to heat the water, while in air conditioner it heats the air. The evaporator coil and condenser coil in water cycle are placed surrounding the drums. The meeting point of two copper pipes is joined by brazing process. .

Polyurethane is a polymer composed of a chain of organic units joined by carbamate (urethane) links. Polyurethanes are thermosetting polymers that do not melt when heated. Hence this material is best suited for insulation purpose. The polyurethane foam (PUF) is applied around the drums covering the coils. This provides thermal insulation and rigid support to the drums. The insulation reduces the heat loss. Fig 5.1: Polyurethane foam (PUF)

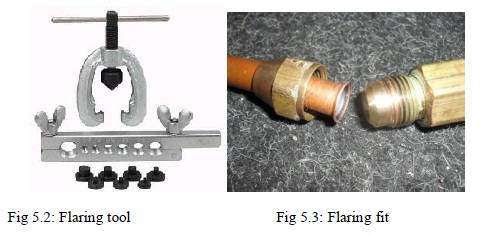

The shut off valves are used to control the direction of flow of refrigerant. Four such valves are attached in two discharge and suction flow lines. The valves are joined by flare fitting. In this process the end of the pipe is enlarged using flaring tool.

Flare fittings are a type of compression fitting used with metal tubing, usually soft steel and ductile (soft) copper, though other materials are also used. Tube flaring is considered to be a type of forging operation, and is usually a cold working procedure.During assembly, a flare nut is used to secure the flared tubing's tapered and also the tapered fitting, producing a pressure-resistant, leak-tight seal. Flared connections offer a high degree of long-term reliability and for this reason are often used in mission-critical and inaccessible locations. Fig 5.2: Flaring tool Fig 5.3: Flaring fit

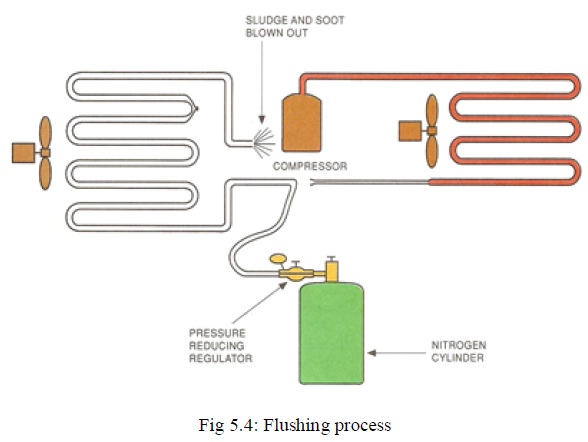

Flushing is performed in order to remove all contamination (dirt) from the system. The smallest particle of contamination causes restriction and problems for a good functioning of the compressor. The compressor must be lubricated at all times. The compressor is the only moving part in the entire system and the only reason for oil in the system. The oil is being circulated throughout the system, which means that all the components (condenser, hoses, tubes, evaporator, drier and accumulator) have some coating of oil internally. Removing the oil (and oil film inside the components) will eliminate all of the contamination from the AC system. It’s the oil that attracts and holds contaminants within the system.Therefore the condenser and evaporator coils have to be flushed before its use. Depending on the method you are using, start by getting some of the flush agent intothe component.

Use pressurized gases (dry air or nitrogen) to push the flush agent through the component. Hold a clean wiper on the opposite end of the component you are flushing. This will allow you to apply some back pressure (holding and releasing the wiper to act as a plug). This help to dislodge and remove debris that may be caught in ‘hard to get’ places. Be sure to perform the same flush procedure in both directions, several times on each component. For the best results, once the system is assembled, but before it is completely sealed, purge the system with nitrogen. By holding the other end of the coil, blow nitrogen through the system so that it will eliminate any moisture that may be left in the system after flushing. This procedure makes the coils free from contaminants.

The cold water and hot water temperature achieved this system is 18ºc and 60ºc respectively. The temperature achieved can be improved by operating the system with any other refrigerant as a substitute to R-22. This system can be adopted in industrial air conditioners so as to utilize the heat energy which is being rejected into the atmosphere more efficiently. It can also be produced for domestic purposes. Efficiency of the system can be improved, if cold and hot water are circulated after attaining certain temperature. The direction of flow of refrigerant within the system can be automated using solenoid valve, instead of operating manually by shut off valve. We can utilize most of the rejected heat by eliminating condenser system in air conditioner.

From the performance test conducted the water temperature can be raised from ambient temperature can be raised from ambient temperature to around 60ºc. The water gets heated from condenser unit of water cycle. Therefore it reduces separate water heating charge. The temperature of cold water can be reduced from room temperature to 18ºc. The air cycle provides good results with optimum efficiency. Thus it is concluded that the modified system performs in similar manner to conventional air conditioners and water coolers.The main advantage of this system is that the hot water is obtained by utilising water heat liberated by condenser of water cooler, without spending extra electric cooler. Therefore this system is economic.The average power consumption and the COP of this system is around 1.1kw and 3.5 respectively, which is similar conventional air conditioner and water cooler. The system uses single compressor to operate different modes of operation. Hence the installation cost is also less. Since this device is multifunctional and works with single compressor, this system is economic compared to conventional air conditions. This principle can be used for household purpose and in automobiles etc.

[1] K. Goldenberg, "What is Automation?" JEEE Trans. Automat. Sci. & Eng., Vol. 9, No. 1, pp. 1-2, 2012.

[2] Zhang Jie, Ren Yan college of urban construction Hebei university of engineering Handan, China

[3] K. Goldenberg, "What is Automation?" JEEE Trans. Automat. Sci. & Eng., Vol. 9, No. 1, pp. 1-2, 2012.

[4] Meckler, G. (1989). “Two-stage desiccant dehumidification in commercial Building HVAC systems.” ASHRAE Trans., 95(2), 1116–1123