Published on Nov 30, 2023

Agriculture is the largest single industry in the world, and seed production is an important segment of this industry. Seed, as it comes from the field, contains various contaminants like weed seeds, other crop seeds, and such inert material as stems, leaves, broken seed, and dirt. Therefore, cleaning of paddy is required. Additionally, non-availability of appropriate paddy cleaning machine at reasonable price is one of the major constraints for initiating small/medium scale manufacture of paddy cleaning machine. Therefore, this working is undertaken to develop an efficient low cost paddy cleaner in view of improving the quality paddy cleaning using conventional methods. To check the performance of the paddy cleaner, a total volume of 1.15kg of uncleaned paddy consisting of 1kg of paddy, 0.05kg of dust and 0.1kg of sand was fed into the hopper. After the cleaning process, the output obtained was 1.022kg of cleaned paddy with 0.994kg of paddy, 0.021kg of dust and 0.006kg of sand. Hence the performance of this machine is very efficient where most of the paddy produced is cleaned.

Agriculture is very important for a country's economic stability and welfare. If a country's agricultural sector is so productive that it can yield enough to feed the country's entire population, it does not have to import food from other countries. If the country's agriculture sector is so productive that it can produce enough to feed the population as well as create a surplus which can be exported, that results in great economic gain for that particular country. If, however, a country's agricultural sector is unproductive and is unable to produce enough to meet the needs of its population, it adversely affects that country's economy since then it has to import food stuff from other countries which costs a lot. As a result the goods are sold in the local markets at higher rates which the most of its population can't afford. Thus, it leads to inflation and economic instability. Therefore, it is very important for any country to have a healthy and productive agricultural sector which can provide for its population and also boost trade with other countries.

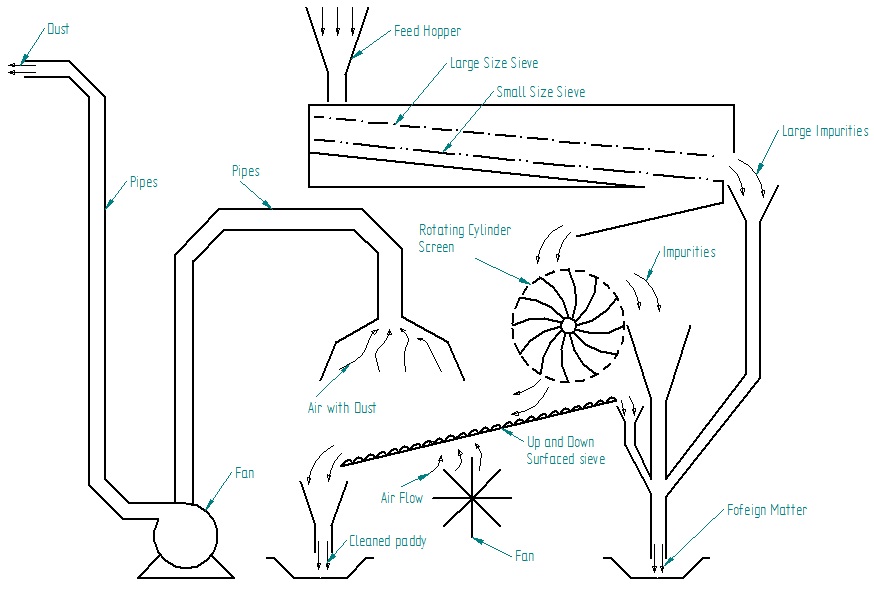

Portable Paddy Cleaning Machine is designed to remove foreign materials and impurities such as sand particles, stones, paddy straws and foreign seeds from paddy. This machine provides farmers an alternative replacement of current conventional method should the farmers want to extract the paddy seed in small scale amount [3]. Currently, they only use a traditional winnow technique as to obtain the seeds to be used next season or before processing paddies to become rice.The performance of this machine is very efficient where the percentage of clean paddy is observed to be at 95%. It helps farmers improvise their traditional method, reduces purchasing cost of paddy seed and utilizes the cleaning process at low cost and less maintenance.

Generally, the hand threshing and the traditional handling used in most developing countries case a larger percentage of foreign matter with the paddy. Thus, more cleaning is required.At this point a rice mill cleaner removes any remaining foreign material that could damage the milling machinery and eliminates foreign material from the milled rice

The paddy cleaning machines currently available in the market/industries are bulky. The existing ones are designed for a higher capacity which makes them more expensive. Thus, it is not suitable to purchase the existing paddy cleaning machine to perform simple cleaning operation. Moreover, these machines are heavy and take up a lot of space. In addition, the current paddy cleaning machines are not portable. In order to overcome the problems associated with the current paddy cleaning machine there is a need which is inexpensive, compact, portable and versatile. Our proposed paddy cleaning machine is capable of removing dust, sticks, stones, and other impurities.

The paddy is cleaned to:

1. Reduce requirements for drying cost.

2. Remove materials that could cause paddy deterioration during shortage.

3. Remove materials that could damage the conveying and milling machinery.

4. Remove materials that cause a reduction in the grade.

5. Reduce storage requirements.

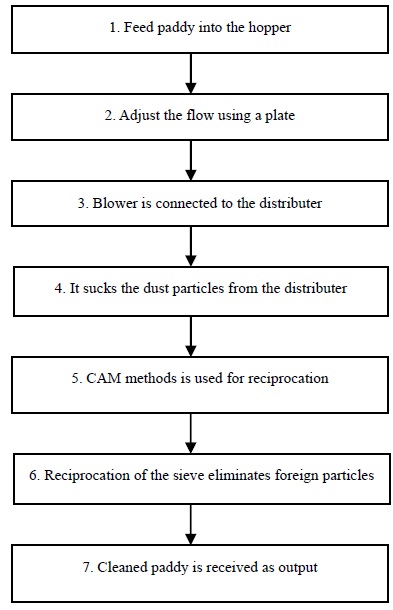

The sequences of operations are as follows

Separation under natural air stream, cleaning with cleaning basket (‘Supa’) and sieving with manual sieve and manual grading have been in vogue to remove chaff and foreign matter and quality improvement through grading using sieve in case of food grains and oilseeds. But seed cleaners and graders achieve very high degree of efficiencies (over 98%) are commercially manufactured and in use. Paddy can be cleaned in large scale compared to manual cleaning. The paddy cleaning machines currently available in the market/industries are bulky. The existing ones are designed for a higher capacity which makes them more expensive. These machines are heavy and take up a lot of space. The current paddy cleaning machines are not portable but we can make it portable in several ways. We can use one motor instead of two and conveyor belts can be used. This will not only decrease the weight and size but will also decrease the cost.

In the longer run, picking by machine mostly turns out cheaper than manual cleaning releasing funds for other quality improvements in the cellar.

A mechanical cleaner is much faster than manual cleaners

Some say one machine does the same work as 20 harvest workers.

A mechanical cleaner is typically done in a much shorter time span than a manual cleaner.

The cleaner can also be sent out in the middle of the night to harvest. This can be a great advantage in hotter climates.

The design of this machine is such that a single operator can do the cleaning operation with ease.

The amount of paddy collected depends upon the moisture content, quality and the type of the crop.

The main concern of the grain getting damaged in the existing cleaning machines is reduced considerably by this machine. Hence grain loss is minimized.

This machine has a limited number of moving parts and hence requires less maintenance.

The filtered paddy is collected directly in a gunny bag using a hopper and hence no scattering takes place as in the case of conventional method.

The machine is cheap and easily affordable by the farmers.

[1] Design data hand book by K. Mahadevan and K. Balaveera Reddy, 3rd edition, CBS publishers and distributors, New Delhi.

[2] Standard Handbook on Machine Design by Joseph Shigley and Charles Mischke, 3rd edition, Tata McGraw-Hill publications.

2. Journal Papers

[1] Karnataka Agricultural Policy document – 2006, Government of Karnataka.

[2] Rice Milling - Poonam Dhankhar M. Tech (Food tech), G.J .U.S & T, Hissar.