Published on Nov 30, 2023

Design and fabrication of arecanut processing unit is presented in this paper. The processing unit consists of four major sub-units i.e. arecanut dehusker, boiler, dryer and sorter, which are designed and fabricated separately and then assembled in one frame. A 3-D printed dehusker peels the arecanut husk and sends peeled nut to the boiler through transfer pipes. The boiled nuts are then sent to dryer equipped with temperature and humidity sensors through rubber conveyers where steam from the boiler is used to dry the nut using a heat exchanger. Then the dried nuts are sorted according to their grades using colour detection camera. The whole unit is designed for 18 kg of raw arecanut, powered by 24 V DC battery and controlled by LabVIEW software. The whole processing unit was tested for its performance and found safe, reliable, and efficient and also reduces the processing time.

In recent years, labour scarcity has emerged as one of the foremost challenges in farming. One crop that has been most affected by this is arecanut. Arecanut production is the largest in India according to FAO statistics and according to this, in 2013, Indian production of arecanut counts for 49.74% of the total world production. In India, Karnataka has the highest production percentage of 62.69%. However, in recent years harvesting and processing of arecanut becomes more difficult for farmers as it involves real hard, physical exertion, younger generations of labour are losing interest, with potentially harsh implication for arecanut cultivation. Researchers all around the world are working on developing arecanut processing machines, most of these machines are semi-automatic and requires human interventions .

Narasimha Bhandari invented an arecanut dehusker machine in 2001 and it was found that the outer surface of arecanut was damaged by sharp blades [9]. Later, in 2002, Vishwanath invented an automatic machine to peel arecanut but production rate was very low compared to manual peeling [10]. The dehusked nut has to be cut, boiled and dried. But no work has been done on developing a single machine which is able to do arecanut dehusking, cutting, boiling and drying. This project work emphasizes on developing an arecanut processing unit. The machine is able to peel the arecanut, cut it in to two halves, boil and dry it to desired hardness in a single pass for two different grades. The design and fabrication of arecanut processing unit was based on arecanut available in the areas of Malenadu. In this work, a safe, reliable and efficient arecanut processing machine is designed and fabricated.

The traditional steps for areca nut processing involves the following steps:

Harvesting of the Areca Nut Palm

Separating the fruits in a bunch

Storing and transportation

Peeling the palm to get the seed (de-husking)

Boiling the seed

Sun drying of areca nut

Sorting of areca nut

This whole process takes up to 10 days. As one can see this involves a lot of time, labour, money and effort to get one quintal of processed areca. And if the farmers don’t get the first grade of areca then there won’t be much profit.

Mechanized method for areca nut processing.

There are existing de-huskers for areca nut but these are not so sophisticated. The nut we get usually sustains certain damage and after drying we don’t get the first grade areca. Apart from this there are no other automation processes available in India for farmers.

This project has mechanized the whole process. The de-husking is done by blades, boiling done by pressurized boilers, drying by air-steam heat exchangers and sorting using cameras and sensors. This machine will reduce a lot of time and manual effort traditionally required.

The objective of this project is as follows.

To process raw arecanut using the mechatronic system, to get maximum efficiency and to utilize the energy

To reduce the processing time and to increase the quality of the product.

By implementing automation reducing the human effort and labour problem.

To reduce human error in the whole process.

To improve the quality of employees.

The methodology of fabrication and working of areca nut processing unit is as follows:

1. The parts of the areca nut are fabricated as the design and then assembled into one unit.

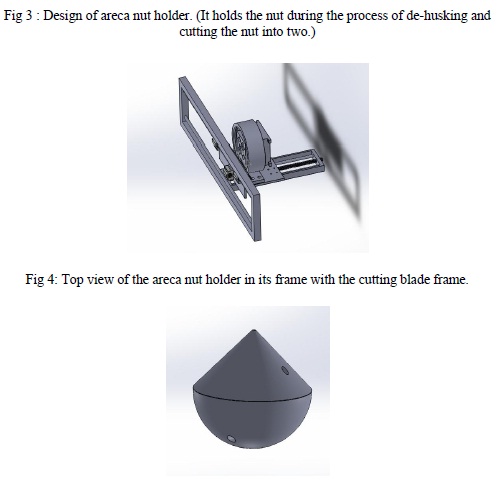

2. The de-husker is fabricated as a separate unit that includes the blade to peel the husk and the support to hold the nut in place. The areca nut holder and block is 3D printed by Mr Vion’s 3D printer. The material for the same is PLA (Poly Lactic Acid). The frame is made up of steel and the blade out of spring steel.

3. The areca nut holder moves in according to the way it has to be cut using pneumatic piston cylinder arrangement.

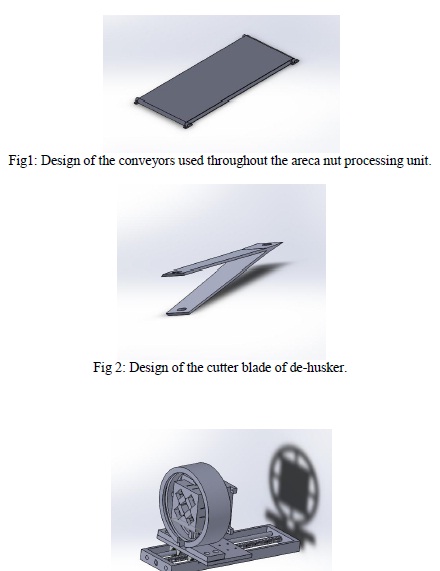

4. There are conveyors to move the areca nut throughout the processing unit.

5. Hoppers are there in the start of the different parts to send the areca nuts into the system. There is a system of pipes and conveyors to move the nuts from one place to another.

6. In the boiler there are two pipes, one for areca nuts and one more for water flow. Required no of areca nuts and water is sent into the boiler and along with this areca nut precipitate is added for the colour. The current system is specifically designed for 18kgs (3000) areca nut. There is constant water flow which is controlled using valves and gauges.

7. The fuel for boiling of areca nut is nothing but the dried husk that was peeled of the seed. The husk is dried in the sun and used as fuel. So the husk from previous cycle is used for current cycle. There are heat sensors to and thermocouples to calculate the temperature of the water while boiling.The boiler is made up of aluminium and the base where the fuel is burnt is surrounded by bricks to trap the heat inside.

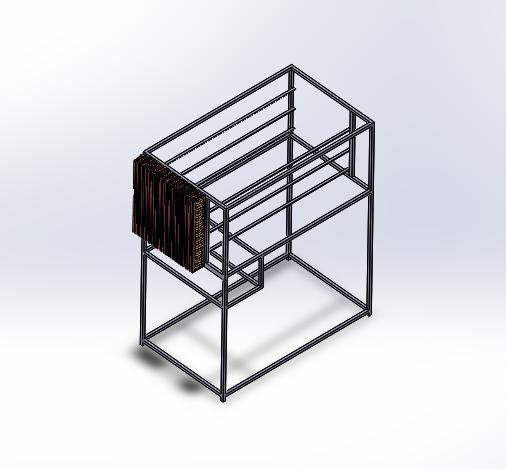

8. The boiled nuts are extracted without the water and then fed to drying system. The drying system is made up of heat exchangers and fans for the complete extraction of moisture from the nuts. And three stepped conveyors to keep all the nuts separately for equal flow of heat throughout the system.

9. The steam from the boilers is used in the radiator to dry the areca nuts. The heat from the steam is used to heat up the surrounding air and thus soaks up the moisture from areca nuts.

10. The next part i.e. sorting system involves sensors, camera, servo motors, and My Rio. The areca nuts are again fed to hopper that sends the nuts one by one. These nuts are detected by the sensors connected to My Rio. The camera clicks an image of the areca nut in test. A program of machine vision is coded into the My Rio. The nut is sensed by My Rio and colour sorted accordingly, the servo motor pushes the nut in the direction of traverse.

11. Thus, the nuts are sorted and the process is complete.

Here are images of designs of the major parts in the areca nut processing unit:

All the four parts of the whole unit namely De-husker, Boiler, Dryer, and sorter are constructed separately and then assembled in one frame. Each part is connected through belts and conveyors. The main parts of the de-husker is blade that peels of the husk of the nut and holder that holds the nut in place. The hopper sends the nut to arecanut slider. Width of the hopper is to make sure that only one arecanut falls on the slider. The hopper blocking is done by part that pushes arecanut. There is a pneumatic cylinder that pushes the arecanut into the holder. Now blade moves to the arecanut and peels it off. The holder then moves by 60° and the process is repeated. This is done three times for the arecanut to be removed completely.

Arecanut is held by grippers and compression springs. The springs are used to push the arecanuts as well. The slider base spring pushes the top of the holder which compresses the base springs. This, in turn, relaxes the gripper spring and the arecanut is pushed out. Once this is done the de-husking part is complete and the seeds of the arecanut are sent for boiling process. The arecanut is sent to the boiler using metal pipes. There is a sorting system, where the camera detects the nuts and sends it to the boiler. In this step, here the nut is boiled in water with the arecanut precipitate that gives the colour to the nut. Once the boiling is done, they are extracted from the boiler without the water and fed to the hopper. This hopper sends the nuts to the dryer for drying.

There are three conveyors for equal distribution of all the nuts. At a time through the hopper one line of arecanut falls onto the conveyor, this is moving, thus filling all the arecanut. Here heat exchangers are used and the steam from the boiler used to dry the arecanuts. There are temperature and humidity sensors to make sure that the nuts are drying properly. Once the arecanuts are dried they are sent to the next hopper for sorting. Here, the hopper sends the nuts one by one. The camera detects the nut. The image from the nut is sent to myRIO where the program for colour sorting is coded.

This unit detects the grade of the arecanut. If it is the first grade of the arecanut then a solenoid valve is actuated and this pushes the nuts into the first outlet. If the second grade is detected, then the conveyor moves and sends the arecanut to the second outlet. Thus, the nuts are sorting according to the grade of the arecanuts.

This project have been designed and fabricated with an intention of providing demonstration to the students, plus being cost effective. Further work has been made in this direction and significant progress has been achieved. However, there is a scope for further improvements.

This design can be incorporated and developed for processing unit for larger weight of areca nuts.

There is always a scope for improvement in performance of a machine and there is for the processing unit as well.

This unit can be converted to a fully automated machine, saving any work from the cultivator.

Smoke coming out of the boiler can be used to dry the husk from de-husker which is further used as fuel for boiler.

A de-buncher can also be added as another part in the assembly unit, so all the processes can be done in one system

An attempt is made to design and fabricate a whole areca nut processing unit. This unit involves de-husking, boiling, drying and sorting of areca nut seeds. This unit can do all the different processes required for the processing of an areca nut seed in one go. This saves a lot of time and manual labour for the cultivator.

In conclusion, one can say that this unit is effective in the processing of areca nut in small scale and the design can be used for production, moreover the design can be effectively used for larger weights of areca nuts with changes in the dimensions and structure.

[1] R. Gunaseelan, S. Shanthi, R. Sowmya, and M. Datta, “Areca nut use among rural residents of Sriperambudur Taluk: A qualitative study”, Indian Journal of Dental Re-search, vol. 18, pp. 11-14, 2007.

[2] Development of e-courses for B.Sc (Agriculture) by NAIP.

[3] Jaysekhars, “Arecanut and Cocoa Production and Marketing Aspects”, 2013.

[4] M. Balasubramanian, and J. S. Panwar, “Mechanical properties of arecanut (Areca catechu linn) as related to dehusking”, Journal of Agricultural Engineering (ISAE), pp. 82–88, 1986.