Published on Nov 30, 2023

In India, there are 210 million registered vehicles as of 31st March 2015. Most of these do not come with the emission standard of Bharat Stage IV for vehicles which was adopted in 2005 by Indian Government. The emissions from these vehicles are toxic and contain harmful gases which causes Air pollution. Air pollution is responsible for many health problem in urban areas. Air pollution is a serious issue and with the 13 out of 20 most polluted cities of the world lies in India. The Air Act was passed in 1981 to regulate air pollution however 2016 Environmental Performance Index ranked India 141 out of 180 countries. . A 2013 study on non-smokers has found that Indians have 30% lower lung function compare to the Europeans. The Global Burden of Diseases study for 2010 had found that outdoor air pollution was the 5th largest killer in India and around 620,000 early deaths occurred from air pollution related diseases.

Carbon filtering is a method of filtering that uses a bed of activated carbon to remove contaminants and impurities, using chemical absorption. Each particle/granule of carbon provides a large surface area/pore structure, allowing contaminants the maximum possible exposure to the active sites within the filter media. One pound (450 g) of activated carbon contains a surface area of approximately 100 acres (40 Hectares). Activated carbon works via a process called adsorption, whereby pollutant molecules in the fluid to be treated are trapped inside the pore structure of the carbon substrate.

Carbon filtering is commonly used for water purification, in air purifiers and industrial gas processing, for example the removal of siloxanes and hydrogen sulfide from biogas. It is also used in a number of other applications, including respirator masks, the purification of sugarcane and in the recovery of precious metals, especially gold. It is also used in cigarette filters. Active charcoal carbon filters are most effective at removing chlorine, sediment, volatile organic compounds (VOCs), taste and odor from water. They are not effective at removing minerals, salts, and dissolved inorganic compounds. Typical particle sizes that can be removed by carbon filters range from 0.5 to 50 micrometres. The particle size will be used as part of the filter description. The efficacy of a carbon filter is also based upon the flow rate regulation. When the water is allowed to flow through the filter at a slower rate, the contaminants are exposed to the filter media for a longer amount of time.

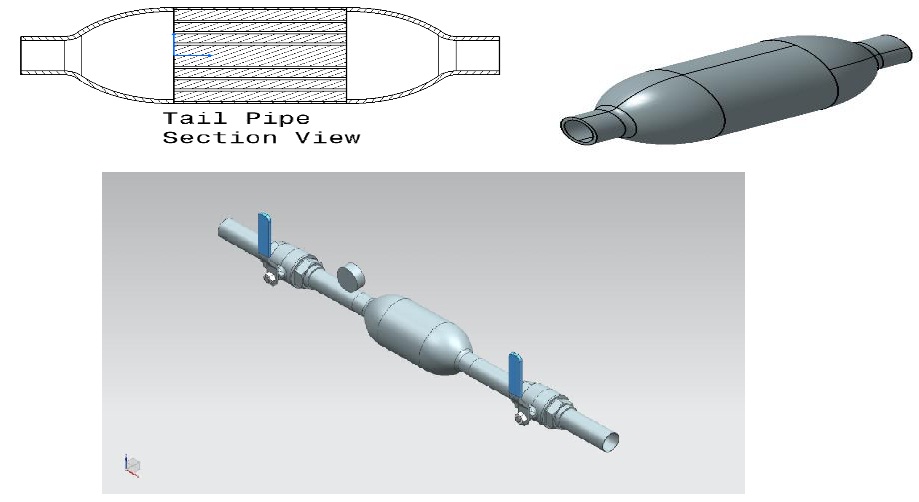

The Aim of our project is to deal with the toxic and harmful gases emitted from the automobiles. Carbon dioxide emission is the common type of gas emitted from the burning of fossil fuels in automobiles. When this CO2 is released into the atmosphere it remains there until it is absorbed in some form. In our project we have presented a dynamic work effort to reduce CO2 emissions through Carbon capture and storage mechanisms.Adsorption technique is followed to control the Carbon emissions from the exhaust gas. The solid adsorbent used in this work is zeolite, were it locks and holds the carbon molecules from the exhaust. The carbon capture tail pipe is successively designed for automotive emission control. It is the first action taken from automobile sector for controlling CO2 emission from the automobile exhaust.

The exhaust gas is allowed to pass into the inlet of the tailpipe. Pressure gets reduced and velocity of the gas increases because of the conical section. The flowing exhaust gas is free to move in all directions inside the tailpipe. As the movement of exhaust gas is not abruptly obstructed anywhere in its path, the back pressure is limited to minimum level. The flowing gas passes over the trap which is fixed at theinner of the tailpipe. Gas entering the perforated sheet mesh holes gets exposure to the zeolite pellets. The exposure of the exhaust gas is maximum by increased in size of the pellets. Zeolite pellets are highly porous and consistent matrix of zeolite that provides the adsorption of impurities.

The exhaust gas containing CO2and other particles are adsorbed by the zeolite pellets. Adsorptions takes place by locking of gaseous CO2 molecules over the porous layer of the zeolite. Adsorption quantity of CO2depends on the type of zeolite used. Maximum adsorption limit of zeolite depends on the amount of exhaust produced from the engine. The material for sheet mesh is considered as steel which has high thermal properties. Sheet mesh also has filtration efficiency which will also filters the black carbon particles up to certain extent. As this is the first device to be designed to reduce CO2 emission. Its limitations will be considered. The Carbon emission levels will be reduced to maximum by implementing this device on the exhaust manifold.

CO2 gas adsorbed in the zeolite mesh can be removed by treating mesh with 5 molar H2SO4. Since Silicon is chemically inert and aluminium passivates, aluminium acts as insulator. Thus in an acid media SO42-ion of H2SO4acts as catalyst and thereby CO2 gas gets desorb and it combines with H+ ions of acid to form methane(CH4) and water(H2O). Methane can be collected in separate container and can be used as a fuel while water as solvent. The chemical reaction is given below:

CO2 +4H2 ----> CH4 + 2H2O

Since the entire model and experiment is focused on the process to adsorb the CO2 gas many limitation has been considered on design and material selection part. In the future advance study can be done for the proper selection of the tail pipe material and its weight consideration so that it can be easily fitted to the vehicle exhaust manifold. This technique can also be used in the factory chimney by applying layer of zeolite around the surface wall of chimney or designing the chimney on the same basic principle, however its lifespan should be considered.

In this analysis it has been presented a dynamic work effort to reduce CO2 emissions from the exhaust manifold using adsorption technique through tail pipe. It’s been found that there is approx. 28-50% reduction in CO2 gas emission using the tail pipe. On experiment using i10 magna @1000 rpm the CO2 gas is reduced from 1800ppm to 1300ppm while on increasing its engine speed to @ 2000 rpm CO2 emission is reduced from 2500ppm to 1300 ppm and the result are satisfactory. Also pressure gauge was also installed to measure back pressure which is very low and hence doesn’t affect the engine performance. It is the first action taken from automobile sector for controlling CO2 emission from the automobile exhaust.

1. Alkama, R., Ait-Idir, F. and Slimani, Z. (2006). Estimation and Measurement of the Automobile. Global Nest J. 8: 227–281.

2. Bond, M. (2007). Technical Report Number SCT-EL-2007- R01-Whale Concept Filtering, South African Bureau of Standards.

3. d' Ambrosio, S., Finesso, R. and Spessa, E. (2011). Calculation of Mass Emissions, Oxygen Mass Fraction and Thermal Capacity of the Induced Charge in SI and Diesel Engines from Exhaust and Intake Gas Analysis. Fuel 90: 152–166.