Published on Nov 30, 2023

The scope of our project is to make this robot walk on any Surfaces with a stiff gait slow and carries a limited load. It could be used for surveillance in sewer maintenance. This project involves the design and fabrication of a kinematic walker. This kinematic walker is six-legged machine did can walk on any surface. It is an arrangement of six linkages did together are powered by a single engine. This device is analogous to a six-legged insect Examined as a spider. The motor can be powered by mains either or a battery. The kinematic walker comprises six legs that move simultaneously to provide motion. Each of synthesis six linkages are made of a four bar mechanism.

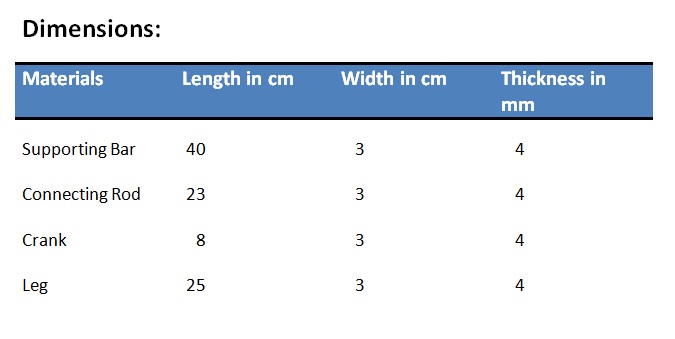

This project presents the kinematics of the movement for a six- legged mobile robot, inspired from the living world, as well as the command and control system, which allow the robot to move on different surfaces with different speeds. For generating the movement, through a command and control system, stepping motors and bars are used. A frame, connecting rod, crank and a lever constitute to obtain the required motion. In this project, the application of simple four bar mechanism is used. The most important benefit of this mechanism is that, it does not require microprocessor, controller and other actuator mechanisms.

The military, law enforcement, Explosive Ordinance Disposal units, and private security firms could also benefit from applications of this mechanism. It would perform very well as a platform with the ability to handle stairs and other obstacles better than wheeled or tracked vehicles. In this mechanism links are connected by pivot joints and convert the rotating motion of the crank into the movement of foot similar to that of animal walking.

The suggested machine uses the basic four bar chain mechanism and slotted lever type quick return mechanism with some modifications. The synthesis of the link lengths is based on Freudenstein’s (algebraic) three accuracy points. The velocity and acceleration analysis of oscillating links explains the effect of change in the crank’s angular velocity and acceleration on all other links. The suggested machine is capable of moving forward and backward, turning right and left and rotating around a point on the commands given.

To give access to places which are dirty.

To give access to places those are dangerous.

Job which are highly difficult.

The structure design of this kind of robots puts great contribution to environmental adaptability and walking stability on complex and nasty non – structure environment.

This study presents a new type of six – legged walking machine.

This six legged walking machine adopts new structure and tripod gait, as well as six legs driven by one motor.

It rotates about 360 degree using hydraulic system, so it reduces friction.

One unique advantage of this walking machine is that the walking movement can be realized without any complex control system.

A second advantage is that the centre of gravity height jitter of this machine is negligible. human’s activities need to be replaced by machine.

Mountain transport,Satellite detection,Disaster relief and rescue,Mineral exploitation,

Military affairs

Material used for project is alluminium because of its low weight.

The main advantage of legged robots is their ability to access places impossible for wheeled robots. By copying to the physical structure of legged animals, it may be possible to improve the performance of mobile robots. To provide more stable and faster walking, scientists and engineers can implement the relevant biological concepts in their design.

Legged robots can be used for rescue work after earthquakes and in hazardous places such as the inside of a nuclear reactor, giving biologically inspired autonomous legged robots great potential. Low power consumption and weight are further advantages of walking robots, so it is important to use the minimum number of actuators. In this context, an objective is set in thi

Literature review reveals that the main concern with the moving leg mechanism is the number of links involved in the design of the structure, since the numbers of links are more it is very tedious to design and operate. For the machine to move in a smooth manner the dimensions of the pieces should precise. More priority should be given to the position of the holes to be drilled since the movement depends on the amount of power or motion which is transferred to the locomotive parts respective to the position of the drills. The key to success for this mechanism is for the designer to make it locomotive even in the roughest of terrains thus the legs form an integral part and should be designed more cautiously. An objective is set to develop a six- legged mobile robot in this project.

It consists of motor or engine mounted at the top.

1. Out of three spur gear one is connected to motor or engine shaft called „Driving gear‟ and remaining two are meshes with driving gear with the help of chain.

2. The crank is connected to the shaft on which two driven gears are mounted.

3. As the motor made to „ON‟ the driving gear drives another two gear , one is clockwise while other is anticlockwise as the gears are rotate in opposite direction.

4. Due to this rotation resulting in the crank rotation

5. Crank moves the forcing link gives the momentum in a particular line of action with help of supporting link.

6. The work of supporting link is to move the arm in a particular profile which made by the end point of arm and move back to its normal position i.e. initial position.

7. All these give the walking motion to the arm like a spider.

The main motive of making the hexapod was to overcome obstacles comes in the way where the wheeled robots are helpless. Like in rocky surface the wheeled bot cannot pass over a rocks or even small stones and in desert or in sand the wheeled bots get struck and slip. Whereas Hexapod locomotion is based on picking and pushing mechanism and its extensive stability can easily conquer rocky and sandy terrains. Due to this aspect Hexapod can be used in defense and in military applications like mine detection and spying. It can be used in research and exploration in such areas where men cannot reach such as in volcanic research. This concept can also be used for exploration and sample testing in other planets and asteroids.

This mechanism can be made more flexible by using different link lengths for front, middle and hind legs. Intelligence can be induced by introducing Sensors and vision to improve the effectiveness of this robot in future. Range of motion and moments available at each joint are the greatest concern as it is important for achieving stance and insect like walking.

In this project, a six legged robot is developed. It is used to step over curbs, climb stairs, or travel into areas that are currently not accessible with wheels without microprocessor control and other actuator mechanisms. It would be difficult to compete with the efficiency of a wheel on a smooth hard surface but as the roughness of the path increases this linkage becomes more viable and wheels of similar size cannot handle obstacles that this linkage is capable of. Further, pivoting arms could be used to optimize

The height of the legs for the waterline.

Increase the platform height.

Reduce the vehicle width.

It allows the legs to fold up compactly for storage

[1] N. G. Lokhande, V.B. Emche, Mechanical Spider by Using Klann Mechanism Shri Datta Meghe Polytechnic,Hingna Nagpur-16,India, 2006.

[2] Yoseph Bar-Cohen, Biomimetics: mimicking and inspired-by biology, California Institute of Technology, March 2005.

[3] Patil Sammed Arinjay, Prof. V.J. Khot Design of Bio-Mimic Hexapod, Department of Mechanical Engg., J. J. Magdum College of Engineering, Jaysingpur, Shivaji University, India,2004.

[4] Gabriel Martin Nelson, Learning about Control of Legged Locomotion using a Hexapod Robot with Compliant Pneumatic actuators, Case Western Research University, May 2002