Published on Nov 30, 2023

Today’s world is of technological developments, which requires huge amount of energy in day to day life. Biogas is the sources of clean and renewable energy, without causing environmental impact are highly desirable. Generation of electricity from biomass is one of the best examples of energy generation. Biogas is an environment friendly and economic alternative to fossil fuel. It is way of sustainable energy production at low cost. Here biogas is produced from cow manure by traditional method and Energy is produced in the form of electricity. In this paper, biogas production rate and their operating parameters are investigated along with gas generator efficiency. Application of produced biogas in electricity generation resulted large amount of energy generation also use of exhaust gases in cow urine distillation resulted in large energy saving.

Biogas is important clean energy resource. Its presence date back up to 10th century B.C. its importance has been increased many fold these days of fuel and energy crunch due to its renewable nature and generation from renewable organic biomass. It is a renewable energy source and in many cases exerts a very small carbon footprint. Biogas typically refers to a mixture of different gases produced by the enzymatic breakdown of organic matter in the absence of oxygen by microorganisms. It can be produced from waste materials such as agricultural waste, manure, municipal waste, plant material, sewage, green waste or food waste. This makes biogas highly important member as far as renewable energy source is concerned. It primarily consists of methane (CH4), Carbon dioxide (CO2) and small amounts of hydrogen sulfide (H2S), Moisture and Siloxanes in the concentrations of 50-80, 25-40, 1-3, 0.5-3% and traces respectively .

Out of these gases methane, hydrogen, and carbon monoxide (CO) are major sources of energy. It has calorific value of 4500 ~ 5500 Kcal/Kg [18]. This energy release allows biogas to be used as a fuel; it can be used for any heating purpose, such as cooking. It can also be used in a gas engine to convert the energy in the gas into electricity and heat. In the UK, for example, biogas is estimated to have the potential to replace around 17% of vehicle fuel. It qualifies for renewable eHYPERLINK "https://en.wikipedia.org/wiki/Energy_subsidies"nerg y subsidies in some parts of the world. Biogas can be cleaned and upgraded to natural gas standards, when it becomes bio methane

The purpose of this study is to optimise the generation of biogas by determining the suitable values of various parameters effecting its generation using Design of Experiment (DOE) by Taguchi method and to implement in a digester designed, fabricated and tested for household purpose. Also an attempt is made to study the effect of iron oxide nanoparticle on the generation of biogas.

1. Selection of important parameter affecting the biogas generation from literature survey. Parameters selected in this project are:

a. Temperature

b. Diameter to depth ratio

c. Retention days

d. Total solid content

e. Additives

f. pH

2. Selection of orthogonal array for Design of Experiment (DOE) - L9 array.

3. Carrying out different trails for various combinations of parameters selected.

4. Plotting out graphs for obtained results to see the affect of each parameter.

5. Forming of regression equation using MiniTab.

6. Carrying out market survey to obtain the waste generated in each kitchen.

7. Designing of the biogas digester for the kitchen waste value generated.

8. Testing the fabricated product for the various variable of regression equation obtained from DOE results.

The floating holder type biogas digester capacity 42 m3 was used in the work. It has floating head a dome like ceiling made up of mild steel having size of 3048 mm OD X 1524 mm height was used in the work. It was coated with red-oxide & epoxy paint which holds the gas until the time of consumption [16]. Digester tank was deep underground well-like structure. The inlet chamber opens from below into the digester which is a huge tank with a dome like ceiling. Digester with 42.47 m3capacities is of circular shape having size is of 3660 mm ID & 4270 mm height. It is divided into two chambers by a partition wall in between. A 230 mm thick brick wall, with having height of 1800 mm bisects this digester. This wall acts as a partition between inlet flow & overflow [16]. It is connected to two overhead tanks with pipes of 113 mm diameter. It has two long cement pipes:

It has inlet pipe which opens into the inlet chamber for introduction of slurry.

It is above the ground level having capacity of 5 m3. It is connected by outlet pipe of digester. It has opening into the overflow tank carry spent biomass for removal of spent slurry.

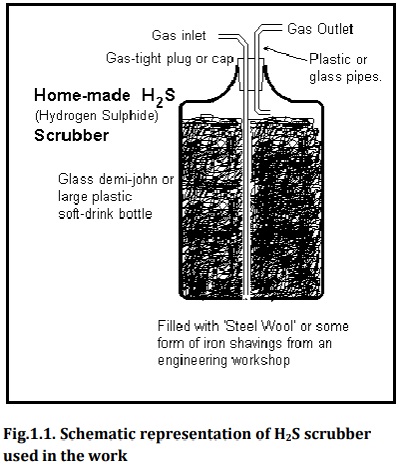

Produced biogas collected in gas holder is passed through bag type moisture trap. Followed by passage through H2S scrubber unit, which has diameter of 113 mm and height of 300 mm. This unit contains MS wire mesh scrap or steel wool of height 230 mm.

Purified biogas fed to electricity generator (7.5 KW capacity) at flow rate of 4.68 m3/hr. direct fire type heat generator with alternator was used for electricity generation.

After electricity generation large amount of heat losses occur due to venting of flue gases. This heat is reused in cow urine distillation unit capacity 90 liters. This is jacketed vessel with flue gas inlet & outlet nozzles. With this, the temperature of exhaust gases is reduced from 300 to 130-140º C.

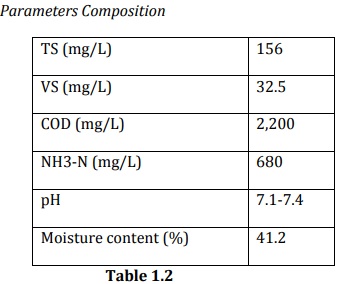

In general use common household biogas plants use mixed kind of feed. Combined animal excreta and household waste in made into slurry and fed to the biogas plant. This slurry making requires large quantity of water, which is generally maintained at 1:2. This affects the enzymatic activity and biogas generation rate. Also the mixed feed changes pH and other characteristics of the feed slurry. Currently we have chosen cow dung as feed material; this would help to maintain feed quality and composition. In addition, this would maintain the quality of feed and once the microorganisms are acquainted to the atmosphere. This would maintain the flow and quality of biogas. Feed composition is as shown in following table.

In current work the feed slurry was prepared from equal quantities of biomass 300 Kg and water 300Kg with ratio is of 1:1. This would maintain the pH 6.6 to 7.6 and other qualities of feed which would maintain biogas quality and flow rate. Prepared slurry is fed into the inlet chamber of the digester through the inlet pipe. Anaerobic fermentation of biomass takes place in the presence of water and produces biogas in the digester . Biogas being lighter rises up and starts collecting in the gas holder. The gas holder now starts moving up. The digester design is made in certain way that it has two compartments.

In one of the compartment fresh feed in introduced, where its fermentation takes place and gas is generated. As more and more gas starts collecting, more pressure begins to be exerted on the slurry. The spent slurry is now forced into the second chamber called outlet chamber from the top of the inlet chamber. When the outlet chamber gets filled with the spent slurry, the excess is forced out through the outlet pipe into the overflow tank. Once the production of biogas begins, a continuous supply of gas can be ensured by regular removal of spent slurry and introduction of fresh slurry. The spent slurry sent to pit for open air dry. Low water content in initial slurry makes it easy for drying and reduces the area required for manure storage. This dried slurry is used as manure for plants and vegetation. Floating gas holder Gas holder is an inverted steel drum resting above the digester.

The drum can move up and down i.e., float over the digester. Floating type digester gas holder is used as it provides some of the advantages like safe gas collection, maintaining the gas at lower pressure. The pressure built up is limited so as to obtain safe gas storage. The gas holder cannot rise up beyond a certain level. As the generated gas contains H2S of biological origin and moisture from biomass, the gas holder should be provided with corrosion resistance. Material of construction for this floating tank is mild steel with red oxide & epoxy paint, which holds the gas until the time of consumption. The gas holder contains outlet valve, which controls supply of biogas. Gas cleaning The generated biogas contains H2S and water moisture as discussed above. Presence of moisture reduces calorific value of biogas produced. Hence it is necessary to remove this moisture to obtain the optimum calorific value. Hence a bag type moisture trap is used for its removal. This trap removes up to 90 % of the moisture.

This moisture trap is followed by H2S scrubber as shown in Fig 1.1. It is used as removal of H2S is necessary as its presence would lead to formation of SOx gases. As these gases would lead to acidic environment and result in corrosion of electricity generator and other equipments ahead. The scrubber is packed bed of in 113 mm diameter and 300mm length, which contains a packing of steel wool with packing density of 7.85 g/cc. As the gas containing H2S approaches, the steel wool will corrode from the bottom upwards taking up the hydrogen sulphide. The iron would get converted to black iron sulphide on contact with H2S. This FeS can be oxidized to ferric oxide by exposure to air. This regenerated FeS can be reused for further removal of H2S. When the black corrosion reaches 75% of the height of the container, the FeS is removed and sent for removal. Two containers are maintained in series to insure complete removal of H2S

The gas is generally generated at ambient conditions. No external heating or cooling media is applied. In Indian conditions the temperature can vary from 12 °C to 42 °C, but majorly the temperature is in the range of 20 to 30 °C. This can affect the gas production in large way. Hence the effect of temperature was investigated in this range.

A linear increase in gas production with temperature is seen in this range. This can be due to increase in microorganism activity in this range. Also the temperature range is suitable for microorganism growth so the favorable growth can be attributed to the same. Beyond this limit i.e. below 10 °C and above 50 °C the growth may be affected adversely. Electricity generation from gas Prepared gas is used in generator having capacity 7.5 KW, for electricity production. The calorific value gas is 5123 Kcal/m3, while is reported value is 4500 – 5500 Kcal/m3. The variation in values is due to presence moisture and composition variation. Gas is supplied to generator at the flow rate of 4.68 m3/hr, which has total calorific value of 23975.6 Kcal/hr.

Theoretical conversion of this heat should generate electricity of 27.88 KW. In actual practice the generator produces 7 KW of electricity. This lower electricity generation is due to low generator efficiency from frictional, alternator and other similar mechanical losses. Thus for three hours of batch around 21 KW of electricity is generated which would save 5-6 units of electricity per day i.e. Rs. 20-25/day. This would result in saving of Rs. 6500-7500 per month .Thus it turns to be the best resource for electricity generation. This non conventional energy source is quite important from national economy also for saving electricity cost.

Heat recovery unit from exhaust gas-After electricity generation, the exhaust gases are coming out at temperature of around 300 °C. Conventionally these exhaust gases are released into atmosphere. Though their flow rate is low but they result in loss of valuable energy and thermal pollution of atmosphere. We thought to utilize this energy in further processes. As the work was carried out in cow animal house, immediate application came fore was distillation of cow urine. This cow urine is used as important material in ayurvedik medicine applications.

1. Experimentation with other parameters affecting the gas generation.

2. Experimentation with other type of feedstock like food leftover, non vegetarian waste, etc.

3. Complete automation of the product.

4. Analysis of the gas generated through gas chromatography

Biotechnological production of biogas is a important way of renewable energy production. Variation in feed composition provides improved biogas production rate. Formed biogas can be cleaned off from moisture and H2S content of formed biogas. Utilization of this biogas for production of energy leads to daily energy generation of ~ 7 KW. This would results in large economical benefits. The exhaust gases from generator are having high temperature and hence it can be utilized in further applications. Its application for distillation of cow urine resulted in distillation of large quantity of urine without any energy requirements. Thus biotechnological biogas is suitable and economically beneficial alternative for conventional fuels available in market.

[1] "Biodigester Design & Construction: Understanding the Basics of a Bio digester." Rural Costa Rica. 2007.

[2] “Biogas” Sustainable Energy Technologies Solutions for Poverty Reduction in South Asia. Inforse-Asia: The International Network for Sustainable Energy.

[3] Arnow, Josh, "bio gas",pp-1-21, 28 May 2005.

[4] Energy for Sustainable Development. History and future of domestic biogas plants in the developing world. Tom Bond*, Michael R. Templeton Environmental and Water Resource Engineering