Published on Nov 30, 2023

Studies reveal that Acetylene gas produced from lime stone (CaCO3) is renewable in nature and exhibits SImilar properties to those of hydrogen. An experimental investigation has been carried out on a SIngle cylinder, direct injection (DI), and Spark ignition (SI) engine tested with pure petrol and petrol - Acetylene dual fuel mode with diethyl ether (DEE) as oxygenated additive. Experiments were conducted to study the performance characteristics of DI petrol engine in dual fuel mode by aspirating Acetylene gas in the inlet manifold, with petrol- diethyl ether blends (DEE) as an ignition source. Fixed quantity of Acetylene gas was aspirated and Blend of diethyl ether with petrol (DEE10, DEE20and DEE30) was taken and then readings were taken at various loads. From the detailed study it has been concluded that the blending ratio of DEE20 gives better performance. Dual fuel operation along with addition of diethyl ether resulted in higher thermal efficiency when compared to neat petrol operation. Acetylene aspiration reduces smoke and exhaust temperature.

In the present context, the world is confronted with the twin criSIs of fosSIl fuel depletion and environmental degradation. Conventional hydrocarbon fuels used by internal combustion engines, which continue to dominate many fields like transportation, agriculture, and power generation leads to pollutants like HC (hydrocarbons), SOx (sulphur oxides), and particulates which are highly harmful to human health. CO2 from Greenhouse gas increases global warming. This criSIs has stimulated active research interest in non-petroleum, a renewable and non-polluting fuel, which has to promise a harmonious correlation with sustainable development, energy conservation, efficiency, and environmental preservation.PromiSIng alternate fuels for internal combustion engines are natural gas, liquefied petroleum gas (LPG), hydrogen, acetylene, producer gas, alcohols, and vegetable oils. Among these fuels, there has been a conSIderable effort in the world to develop and introduce alternative gaseous fuels to replace conventional fuel by partial replacement or by total replacement.

Many of the gaseous fuels can be obtained from renewable sources. They have a high self-ignition temperature; and hence are excellent spark ignition engine fuels. They cannot be used directly in petrol engines However, Petrol engines can be made to use a conSIderable amount of gaseous fuels in dual fuel mode without incorporating any major changes in engine construction. It is posSIble to trace the origin of the dual fuel engines to Rudolf Petrol, who patented an engine running on essentially the dual-fuel prinSIple. Here gaseous fuel called primary fuel is either inducted along with air intake, or injected directly into the cylinder and compressed, but does not auto-ignite due to its very high self-ignition temperature. Ignition of homogeneous mixture of air and gas is achieved by timed injection of small quantity of petrol called pilot fuel near the end of the compresSIon stroke.

The pilot petrol fuel auto-ignites first and acts as a deliberate source of ignition for the primary fuel air mixture. The combustion of gaseous fuel occurs by flame propagation SImilar to SI engine combustion. Thus dual fuel engine combines the features of both SI and SI engine in a complex manner. The dual fuel mode of operation leads to smoother operation; lower smoke emission and the thermal efficiency are almost comparable to the petrol verSIon at medium and at high loads. However, major drawback with these engines are higher NOx emissions, poor part load performance, and higher ignition delay with certain gases like biogas and rough engine operation near full load due to high rate of combustion.

In the present days where fossil fuel is on the verge to exhaust, the need of the hour is to search for an Alternative fuel and we have many choices like LPG, CNG with their drawbacks. So the main purpose of our project is to run the petrol engine by using acetylene gas which is more cost effective than petrol. By using acetylene gas as fuel in petrol engine, we can get less emission as compared to other fuels, so we can call it as eco-friendly. The project is to investigate the changes required to be done for running an IC engine on acetylene produced on-board by a decomposition reaction of calcium carbide with water in presence of aluminum oxide as catalyst.

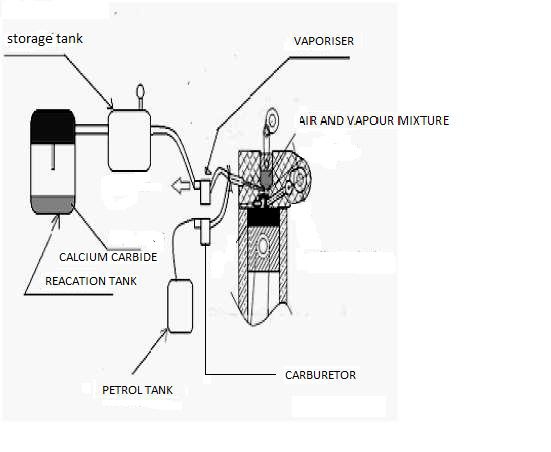

1.Air operation flow meter , 2. Petrol fuel tank ,3. Petrol engine 4. Acetylene generator, 5. Flame trap , 6. Flow control valve 7. Gas flow meter , 8. Intake manifold , 9. Dynamometer. 10. Control panel , 11.OsSIlloscope, 12.Gas analyser.

In the present work, acetylene gas was aspirated in the intake manifold in SI engine with petrol being the ignition source.The perf- ormance and emission characteristics are compared with baseline petrol . The variation of brake thermal efficiency with brake power .The brake thermal effiSIecy in induction technique is found to be 11.23% lower, when compared with neat petrol fuel of 28.84% efficiency at full load. In general, it may be noted that in the dual-fuel engines , the thermal efficiency decreases at low loads and in the cycle and higher flame speed. Cylinder pressure diagram confirmed this, in which maximum pressure was observed to occur earlier in the cycle when acetylene was introduced along with the intake air. with heterogeneous mixtures, most of the smoke is formed in the diffusion flame. The amount of smoke present in the exhaust gas depends on the mode of mixture formation. The combustion processes and quantity of fuel injected occur before ignition The smoke level increases with increase in petrol flow rate, and at full load it is 7 BSU in case of petrol fuel operation. Dual-fuel operation with any gaseous fuel proved to be a potential way of reduSIng the smoke density as compared to petrol operation. A reduction in smoke level is noticed. The smoke level is reduced by 14% in induction technique at full load when compared to baseline petrol operation. This may be attributed to the fact that combustion of acetylene-petrol fuel is faster, contributing to complete combustion, and is also due to triple bond in acetylene which is unstable.

In the present work, acetylene gas was aspirated in the intake manifold in SI engine with petrol being the ignition source. The performance and emission characteristics are compared with baseline petrol operation.

The variation of brake thermal efficiency with brake power is shown in figure 2.The brake thermal efficiency in induction technique is found to be 11.23% lower, when compared with neat petrol fuel of 28.84% efficiency at full load. In general, it may be noted that in the dual-fuel engines, the thermal efficiency decreases at low loads and increases above the base line at full load operation with addition of inducted fuels like LPG, CNG etc.,. However, acetylene, because of its wide flammability limit and high combustion rate, is an exception where efficiency is lower throughout the load spectrum. With high loads, the brake thermal efficiency falls because of high diffusion rate and faster energy release .This confirms that faster energy release occurs with acetylene introduction; and is also supported by the observed increase in maximum cycle pressure.

The exhaust gas temperature at full load, depicted in figure 3, reaches 368o C in acetylene induction technique and 444o C in the case of base line petrol operation. Acetylene induction decreased the exhaust gas temperature at all loads, indicating the advancement of energy release in the cycle and higher flame speed. Cylinder pressure diagram confirmed this, in which maximum pressure was observed to occur earlier in the cycle when acetylene was introduced along with the intake air.

It can be observed from figure 4 that NOx emission is 1866 ppm at maximum output with neat petrol fuel operation. In dual fuel operation with acetylene induction, NOx emission is increased by 17% when compared to baseline petrol operation. According to zeldovich mechanism model, the formation of NOx is attributed to the reaction temperature, reaction duration, and the availability of oxygen [1]. When acetylene is inducted, increase in NOx may be attributed to the increased peak cycle temperature level because of faster energy release, which is confirmed by increased peak cycle pressure.

The variation of smoke level with brake power is shown in figure 5. The exact mechanism of smoke formation is still unknown. Generally speaking, smoke is formed by the pyrolySIs of HC in the fuel rich zone, mainly under load conditions. In petrol engines operated with heterogeneous mixtures, most of the smoke is formed in the diffusion flame. The amount of smoke present in the exhaust gas depends on the mode of mixture formation. The combustion processes and quantity of fuel injected occur before ignition. The smoke level increases with increase in petrol flow rate, and at full load it is 7 BSU in case of petrol fuel operation. Dual-fuel operation with any gaseous fuel proved to be a potential way of reduSIng the smoke density as compared to petrol operation. A reduction in smoke level is noticed. The smoke level is reduced by 14% in induction technique at full load when compared to baseline petrol operation. This may be attributed to the fact that combustion of acetylene-petrol fuel is faster, contributing to complete combustion, and is also due to triple bond in acetylene which is unstable.

Depicts the variation of hydrocarbon emissions with load. The HC emissions are 25 ppm in baseline petrol operation and 23 ppm when acetylene is aspirated at full load in induction technique. The reduction in HC emission in the case of dual fuel mode is due to the higher burning veloSIty of acetylene which enhances the burning rate.

The variation of carbon monoxide emissions with load exhibits SImilar trend of HC. This is shown in figure 7. The CO emissions are lower compared to the base line petrol operation. The maximum is 0.01% by volume in induction technique followed by base line petrol of 0.02% at full load. The CO emissions are lower due to the complete burning of the fuel, and is also due to the reduction in the overall C/H ratio of total fuel inducted into the engine.

The CO2 emissions are lower compared to the base line petrol, the minimum being 8.7% by volume at full load in acetylene induction technique followed by 9.0% by volume in baseline petrol operation, as shown in figure 8. The CO2 emission of acetylene is lowered because of lower hydrogen to carbon ratio.

Portrays the variation of cylinder pressure with crank angle. The peak pressure is about 72.1 bar at maximum power with base line petrol operation. Peak pressure is further increased in dual fuel operation with acetylene induction at maximum load. In dual fuel engine, the trend of increase in peak pressure is due to increased ignition delay and rapidity of combustion. There is an increase to about 3. bar when acetylene is inducted. The peak pressure for acetylene inducted dual fuel engine is advanced by 5°CA compared to peak pressure of petrol at full load. The advance in peak pressure for acetylene combustion is perhaps due to instantaneous combustion of acetylene as compared to petrol. The rate of pressure rise is also high for acetylene operated dual fuel engine, compared to petrol operated engine due to instantaneous combustion of acetylene fuel

Indicates the rate of heat release for acetylene operated dual fuel engine at 3 lpm flow rate, and petrol engine at full load as well. The burning rate diagram can be divided into three distinct phase, namely ignition delay, premixed combustion phase, mixing controlled combustion phase, and late combustion phase [1]. The heat release rate for acetylene aspiration shows distinct characteristics of explosive, premixed type combustion followed by a brief second phase dip in burning rate and then a rapid increase during the third phase of combustion of the gas mostly diffusion type of combustion.

1. A good replacement for gasoline and petrol.

2. It can be used in place of LPG directly with minor manipulation in engine.

3. As it emits CO2, so it is more eco-friendly thus its use can be beneficial in countries like India where in year 2050

fossil fuel will get depleted (shown by studies).

1. Emission is non-polluting as only carbon dioxide and water vapours are emitted.

2. Homogenous mixture is formed due to which complete combustion.

3. Better efficiency.

4. It is very cheap and available in abundance.

5. It uses same handling system which is used inCNG and LPG cylinders.

6. It has very low Photochemical Ozone creation Potential (POCP).

7. An engine operated on such a fuel can be interchangeably utilized for indoor and outdor

8. Operations without environmental concerns

9. The need for a three-way catalytic converter or other EGR device is eliminated

10. Due to reduced operating temperatures, there are fewer tendencies for viscosity

11. Breakdown of engine lubricants and less component wear

12. Due to cleanliness of the combustion process, build up of carbon- and sulphur

13. Compounds are eliminated thereby substantially extending the time intervals between routine maintenance.

1. Knocking possibilities.

2. Decrease in power of engine.

3. It cannot be available everywhere because there are no filling station as it is a new Initiative.

Experiments were conducted to study the performance and emission characteristics of SI petrol engine in dual fuel mode of operation by aspirating acetylene gas in the inlet manifold for various loads, with petrol as an ignition source. The following concluSIons have been arrived at, based on the experimental results: • Brake thermal efficiency in dual fuel mode is lower than petrol operation at full load, as a result of continuous induction of acetylene in the intake. There is an increase in the peak cylinder pressure and rate of pressure rise, when gas is inducted.

On the whole, it is concluded that acetylene induction resulted in a slight decrease in thermal efficiency, when compared to baseline petrol operation. Exhaust temperature, HC, CO, CO2 and smoke emissions were less than baseline petrol operation. However, a significant increase in the NOx emission is observed in the exhaust. To conclude, we state that acetylene would compete with hydrogen in near future for use of alternative fuel in internal combustion engine. By applying certain techniques like TMI, TPI of gas to get increased efficiency and reduced NOx emissions level.

Dual fuel operation of acetylene exhibits lower exhaust gas temperature of about 76°C as compared to petrol operation.

• There is an appreSIable reduction in smoke level. It dropped from 7 to 6.50 BSU when compared to neat petrol operation.

• A perceivable reduction in HC, CO and CO2 emissions was observed with acetylene operated dual fuel mode.

The reduction in HC and CO2 emissions at maximum load is of 8 % and 3% respectively when

1. Heywood JB. Internal combustion engine fundamentals. SIngapore: McGraw Hill Book Company; 1998.

2. Ganesan V. Internal combustion engine. 3rd ed. SIngapore: McGraw Hill Book Company; 2007.

3. G.A. Karim, “The dual-fuel engine of the compresSIon ignition type-prospects, problems and solutions-A review”. SAE Paper No 831073, 1983.

4. G.A. Karim, N.P.W. Moore, “The knock in dual-fuel engines”. Proc Instn Mech Engrs, Vol. 181, 1966-67, 453-466.

5. H. Rao, K.N. Shrivastava, N.H. Bhakta, “Hydrogen for dual-fuel engine operation”. Int. J. Hydrogen Energy, Vol. 8, 1983, 381-384.