Published on Nov 30, 2023

This title presents the concept for design and analysis of crop cutter. The crop cutting is important stage in agriculture field. Currently in India former used conventional method for the crop cutting i.e. the conventional method for crop cutting is as manually cutting using labour but this method is lengthy and time consuming.This project aim is to design and analysis of small field crop cutter machine for small height crop. To analysis cutting rollerand horizontal cutting blade by using Pro-eand anises software. The machine consists of petrol engine to operate cutting roller and blade. When compare to manual crop cutting by and this machine has a capacity to cut the crop in faster. This machine to helpful for both the small as well as big farm.

Agriculture is the backbone of India. In India agriculture has facing serious challenges like scarcity of agricultural labour, in peak working seasons but also in normal time. This is mainly for increased nonfarm job opportunities having higher wage, migration of labour force to cities and low status of agricultural labours in the society. In India two type of crop cutting like as manual method (conventional method) and mechanized type of crop cutter. The crop cutting is important stage in agriculture field. Currently Indian former used conventional method for crop cutting i.e. cutting crop manually using labour but this method is very lengthy and time consuming.

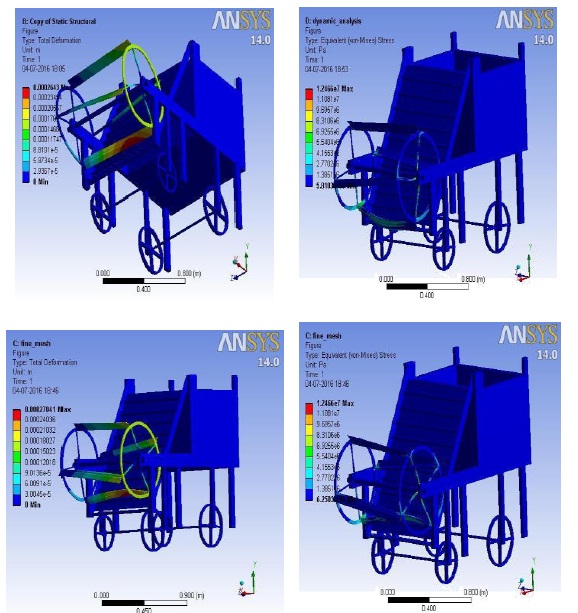

To design and analysis the crop cuter machine which is help to the Indian former which is in ruler side and small farm. It will reduce the cost of crop cutting in field. It will help to increase economical standard in Indian former. The design of the crop cutting machine will be presented by using KERO drawing software. The force analysis on the cutter blade. The force analysis on the roller cuter blade by using ANSYS 14.0 software. This rendered the cutter safe from the cutting forces

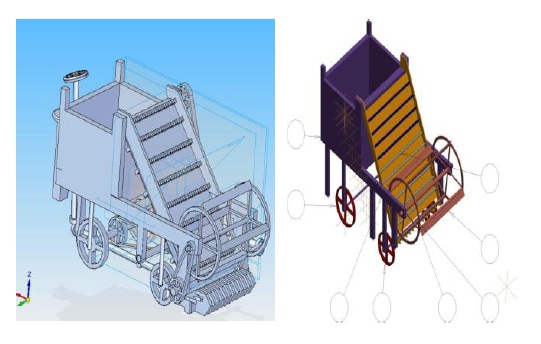

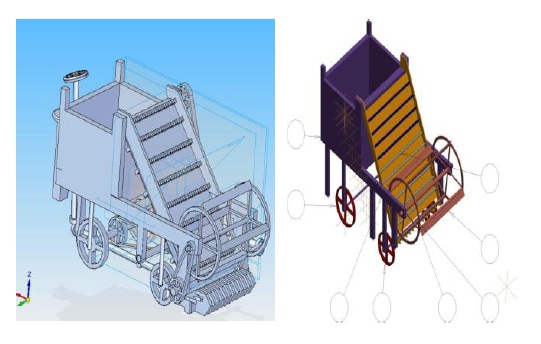

In this project the idea is to make the mechanization of small scale crop cutting machine. The machine focuses to combination of cutting and collecting the crop for small scale farmers. Different parts of a machine will be mounted on strong chassis. The wheel will be attached to this chassis. The petrol engine is mounted on the chassis which provides the power to the wheels to move by chain drive and gear.

These mechanisms to provide the power the cutter byusing the belt drive to the roller cutter andcutting blade. The power transmitted engine to cutter shaft by using belt drive and pulley.

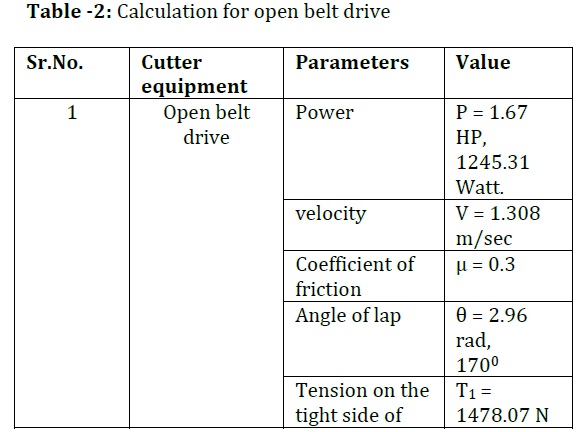

Calculation for open belt drive and shaft of the rolling cutter

From the observation on rolling cutting blade and cutting blade, it is understood that all the problem with the material property and design.

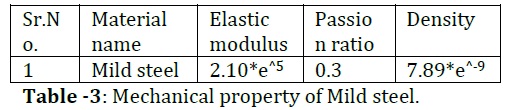

At first the study of the cutters has to carried out. After feasibility study of blades. We have to design the existing and the proposed design using the modeling softer ware KERO. After the modeling process the analysis of the existing and modified design with varying material property will be made.The material property for these steel tabulated below.

The static analysis and dynamic analysis on the rolling cutting blade is done. The force generated for the static analysis van misses tress is 1.2466e+007 Pa and the deformation of the blade is 2.7041e-004m. In this way rolling cutting blade is safe

The crop cutting machine to develop is just concept. It innovative three stage crop cutting machine ling the like as cutting the crop, Reaping, and winnowing. In this paper to design and analysis different cutting equipment like as roller crop cutting and cutting blade. The machine can be run on petrol engine .the machine operated by single labor. The machine will eliminate the labor problem in peak session for crop cutting period. This machine is helpful for the both the small as well as big farm.

The static analysis on the cutting blade is done. The van misses stress 1.6609e+007 and deformation of the cutting blade is 9.0722e-005m. In the way cutting blade is safe.

1. State of Indian Agriculture 2012-13, Indian Government Analysis.2. “Design and Development of manually Operated Reaper” Mr. P. B. Chavan, Mr. D. K. Patil, Mr. D. S. Dhondg.(IOSR-JMCE) Journal of Mechanical and Civil Engineeringe-ISSN:

2278-1684,p-ISSN: 2320-334X, Volume 12, Issue 3 Ver. I (May. - Jun. 2015), PP 15-22.

3. “Fabrication and performance test of an Ultraportable Crop cutter” Mr. G Maruthi Prasad Yadav, GMD Javeed Basha IJRSET Volume 2, Issue 2 Pages: 13-253.”Design and fabrication of small scale Sugarcane Harvesting Machine” Adarsh J Jain, Shashank Karne, Srinivas Ratod, Vinay N1 Toted and Karan ISSN 2278 – 0149 .ijmerr Vol. 2, No. 3, July 2013© 2013 IJMERR.

4.”deign of tractor front mounted Pigeon pea stem cutter” Atul R. Dange, S. K. Thakare, I. Bhaskarrao and Umarfarooq momin. Journal of Agricultural Technology 2012 Vol. 8(2): 417-433ISSSN 1686-9141