Published on Nov 30, 2023

The main source of energy has been coal, oil, natural gas, nuclear energy, wood and coal. However, all these sources are limited and are the main cause of pollution and this has led to development and more focus on sustainable energy supply with minimum pollution effects. Hence research and analysis has shown that wind energy, solar energy and biomass are the most prominent solutions to the above problems because they are eco-friendly and readily available in nature. Wind energy can be generated using windmills that provide mechanical energy that is used directly on machinery e.g. water pump and grinder; or wind turbines that provide electrical energy. The main objective of our project was to design a windmill and therefore our scope will be limited to a windmill for water pumping water. Windmills are classified into two main types based on the axis about which they rotate. Horizontal axis has the main rotor shaft running horizontally and if the rotor must be oriented in the direction of the wind, a wind vane is coupled with a servomotor. Vertical axis has the main rotor shaft running vertically.

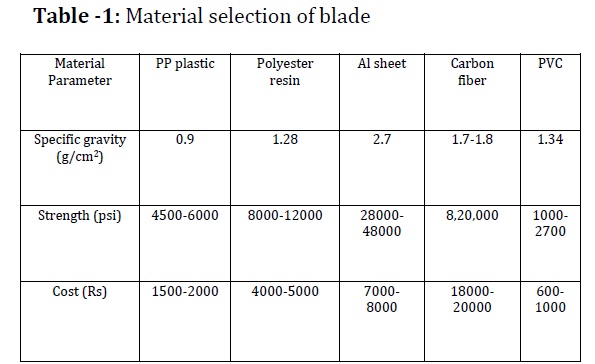

The rotor assembly can have two or more blades depending on the desired solidity. In our design, we used a horizontal axis windmill with 3 blades, tensile strength 31 N/mm², density 0.855 g/cm3, length of blade 30 inch (2.5 feet) and strength of blade is 4500-6000 psi.

Energy today has become ultimate need of world. Today every application which has been develop in the world require energy supply for its functioning but population of the world is increasing causes tremendous pressure on the energy and mineral resources leading to their exploitation. More ever the greenhouse gases are increasing due to exploitation of these resources. So we need to focus an alternative solution for this problem. Light, wind, Biomass, water etc. are some of the alternative for this problem. Wind is one of the most clean and highly abundant resources in nature.

This is air in motion and it is a natural resource that is freely available in space and moves at varying speeds depending on the geographical location

Wind energy originates from solar energy where the sun heats the atmosphere unevenly causing some parts to be warmer than others. The warmer patches of air rise and other air patches blow in to replace them. Thus alternating air flow which results in wind.

Windmills are machines that are used to harness the kinetic energy of the wind which blows over the blades rotor assembly causing it to rotate on a shaft. The resulting shaft power is then used to provide mechanical work for pumping water.

Lifting the water without using electricity and fossil fuel.

Setup must be nonpolluting and less noise operation.

Setup cost should be less and maintenance free, one time investment is preferable.

It must produce some amount of power.

Installation must be easy and cheap.

Fuel must be cheap, clean and renewable.

Solution for the above problem must be eco friendly.

There are various materials available for design of blade such as wood, fiber, steel, aluminum, carbon fiber, polypropylene plastic. Out of which we have used polypropylene plastic (pp) type material for our design because of following reasons: Polypropylene blade performance and also to decrease process temperatures by adding special particles like nano, fillers.etc in order to replace the current thermo sets by utilizing the benefits associated with the thermoplastics like emission free, process-ability, recyclability, and weld-ability. Polypropylene materials offer higher strength to weight properties than thermo sets, therefore leading to lighter aero foils which can lead to cheaper transport costs and reduced turret weights.

From the above table we can see that the specific gravity of polypropylene plastic is less as compared to other material hence we choose PP plastic material for manufacturing of blade also the strength per psi is also within the normal range which is satisfactorily good for moving of any blade in wind.

Aerodynamic performance is fundamental for efficient rotor design. Aerodynamic lift is the force responsible for the power yield generated by the turbine and it is therefore essential to maximize this force using appropriate design. A resistant drag force which opposes the motion of the blade is also generated by friction which must be minimized. Turbines operate for long periods at ground level where insect and dust particulate build up is problematic. This build up known as fouling can have detrimental effects on the lift generated. Provision is therefore made for the reduced sensitivity to fouling of wind turbine specific aero foil designs. The structural requirements of turbine blades signify that aero foils with a high thickness to chord ratio be used in the root region. Such aero foils are rarely used in the aerospace industry. Thick aero foil sections generally have a lower lift to drag ratio. Special consideration is therefore made for increasing the lift of thick aero foil sections for use in wind turbine blade designs.

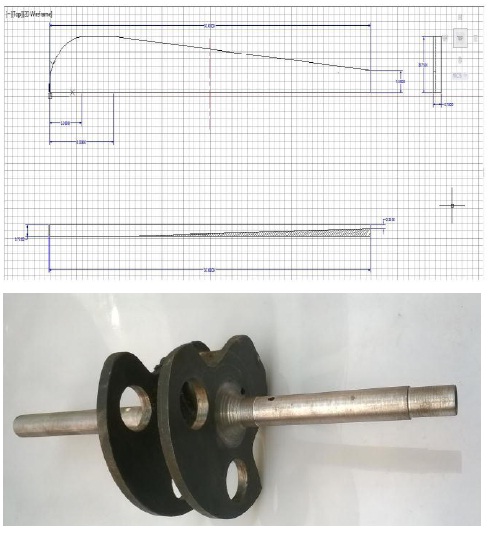

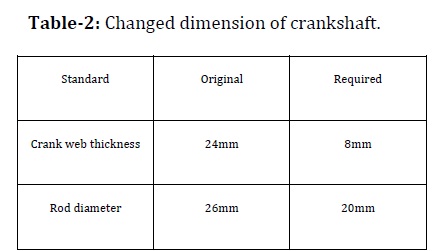

Another most important component for the smooth functioning of prototype is crankshaft. Crankshaft should poses high strength, rigidity and toughness due to these requirement they are manufactured by casting and forging production techniques. Crankshaft is component connected between the turbine blade and connecting rod. With the rotation of turbine blade, certain mechanical motion is obtained which is transmitted to the crankshaft leading to rotary motion of connecting rod with piston in the pumping assembly.

The size of crankshaft was too large so we have fabricated it to the required size for our project. Above table shows the original size & required size.,

Connecting rod is long slender component between crankshaft and piston assembly via sew-saw mechanism. Mechanical motion obtained from the crankshaft for the reciprocation of piston rod in pumping assembly is transmitted via connecting rod. Connecting rod should have high ultimate tensile stress, resistance for the bending, fatigue stresses so it should be manufactured by casting and forging production techniques

Sew-saw mechanism is the basic principle for reciprocation of piston in pumping assembly is achieved by sew-saw mechanism. Blade rotate further leading to the rotary motion of crankshaft. This rotary motion is further transmitted in the form of transverse motion for the reciprocation of piston rod in pumping assembly.

There are two types of pumps;

1. Volumetric (Positive displacement pump)

2. Centrifugal (Roto-dynamic pump)

Out of which we have used positive displacement pump.

Positive Displacement Pump are further categorized as

Rotary lobe pump

Progressive cavity pump

Rotary gear pump

Piston pump

Diaphragm pump

Screw Pump

Gear pump

Hydraulic pump

Hence for better displacement and sufficient water discharge we have used “Piston Pump (single acting reciprocating pump)” Piston pumps are generally connected to a surface-mounted motor and used to pump water from shallow wells, surface water sources, and pressurized storage tanks, or through long pipes. The suction head is limited to 6 meters. They are not tolerant to silt, sand, or abrasive particles because the piston seals are easily damaged. Filters may be used to remove the dirt.

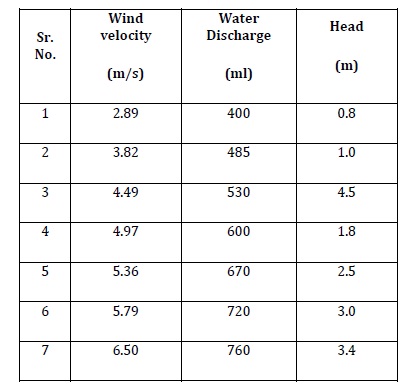

To conduct trail we have done set up of wind operated water pump. Windmill blades made up of polypropylene (pp) plastic. Turbine is fixed on crank shaft. Crank shaft is mounted on supporting stand. To permit relative angular motion crank shaft is mounted between bearings. One end of connecting rod is connected to crank shaft and other end connected to sew-saw mechanism by using connecting pin. A piston rod of pump is connected to one end of sew-saw mechanism. All these assembly mounted on structure in such a manner so that we should get the desired motion of piston rod.

When wind is imparted on blade kinetic energy of wind is converted into mechanical energy as an angular motion of crank shaft. This angular motion of crank shaft is converted into transverse motion by sew-saw mechanism. Transverse motion is given to piston of pump so that piston will move in transverse direction. When crankshaft rotates the piston will moves in upward and downward direction inside the cylinder. When piston moves from bottom dead centre to top dead centre of cylinder, vacuum is created due to which water is sucked inside cylinder. When piston moves from top dead centre to bottom dead centre pressure of water increased above atmospheric pressure at the end water is discharged through pipe. Due to pump is single acting reciprocating pump thus there is alternate flow of water in the delivery pipe. The shaft power can be used to generate electricity by using alternator, which is mounted on crankshaft.

Efficiency or power output of pump can be improved by optimizing blade parameters such as blade thickness , blade length , blade profile , number of blades etc.

By keeping solar panels to rotate the wind mill we can pump easily where no power consumption is required to pump the water.

Efficiency or power output of pump can be improved by changing the gear dimensions and slider crank mechanism.

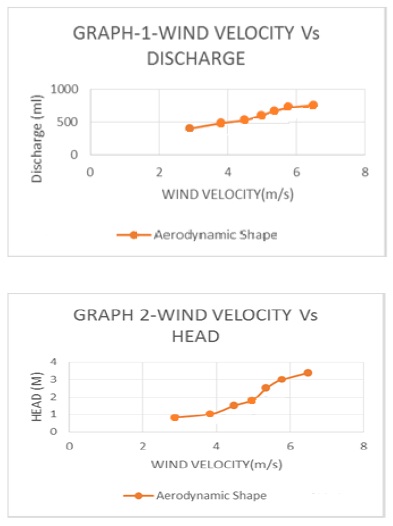

The goal of project is accomplished from the requires analysis and fabrication of prototype that is utilization of wind power to pumping water and generate electricity. Most preferable and suitable material from the design consideration point of view satisfying all the optimum condition and requirement is found to be Polypropylene Plastic. From result we have seen the efficiency of aerodynamic shape blade.

[1] K.Suresh Babu, N.V.Subba Raju, M. Srinivasa Reddy, Dr. D. Nageswara Rao, the material selection for typical wind turbine blades using a madm approach& analysis of blades‖, MCDM 2006, Chania, Greece, June 19-23, 2006.

[2] Ayşegül Akdoğan Eker, Bülent Eker, General Assessment of Fiber-Reinforced Composites Selection in Wind Turbine Blades, Mechanical Engineering Department, Yıldız Technical University, İstanbul, Turkey, 20, December 2013.

[3] R.T. Durai Prabhakaran, future materials for wind turbine blades –A critical review‖, Section of Composites and Materials Mechanics, Department of Wind Energy, Technical University of Denmark, Risø Campus, Frederiksborgvej 399, 4000 Roskilde, Denmark.

[4] Samir Ahmad, Dr.Izhar-ul-Haq, Wind Blade Material Optimization‖, Main Ibrahim Hyderi road, Karachi, Pakistan, Advances in Mechanical Engineering, ISSN:2160-0619 Volume 2, Number 4, December, 2012.