Published on Nov 30, 2023

Now a day’s construction revolution has made the contractors to equip their construction in such a way so as to perform the highest output with as minimum construction cost as possible. In order to have highest output the parameters like accuracy, precision, quality and cycle time have to be optimized, this optimization is possible either by having a skilled man power or automating the system. In the first case, continuously doing the same kind of work for long time will cause fatigue resulting in lower efficiency. So it would be better to automate the system if work nature if of same is in case of large construction. With the automation it is also possible to have higher efficiency, accuracy and quality. Contractors are also concerned with safety levels of the worker as well; automation also provides a solution on the safety aspects of both worker and machine. This project is a welcome edition and a new innovative concept where we thought this as an ideal alternative for the manual method. This Project relates to the design and fabrication of semi-automatic wall care machine.

This project will not only provide an alternative to manual labour used but also with high efficiency and portability.

The construction revolution of today has made the contractors to equip their construction so as to perform the highest output with minimum construction cost. In order to have highest output, parameters like accuracy, precision, quality, and cycle time have to be optimized. This is possible either by having skilled manpower or by automating the system. With the constant increase in the demand of construction, contractors are forced to increase their construction and also the quality of the construction to remain in the competitive market. The construction industry in most countries amounts to 10–20% of the GNP [2], making it the largest economic employing sector. It is still labour dependent and most of the work involved is repetitive.

The growth of any country is dependent on the construction industry; hence, it is of prime economic significance to many industrial sectors. Intense competition, shortage of skilled labour, and technological advances are forcing rapid changes in the construction industry, thus encouraging its automation. The construction of buildings, apartments, complex, shops, and homes are basic requirements of human being. In this construction area, plastering is necessary for decorating the wall. Plastering work or plastering refers to the construction or ornamentation done with plaster [3], such as a layer of plaster on an interior wall or plaster decorative mouldings on ceilings or walls. The tools and materials for this include trowels, floats, hammers, screeds, a hawk, scratching tools, utility knives, laths, lath nails, lime, sand, plaster of Paris, a variety of cements, and various ingredients to form colour washes.

Our aim of this project is to render the plasters on walls mechanically and automating the process.

This project aims in reducing the intervention of trained workers.

This innovative method keeps up with the ever-changing world of building automation.

To simplify the whole process and to attain better work finish with minimal cost at minimal time.

Observation and analysis of the conventional methods used to plaster walls.

Market survey about any existing tools, equipment and machineries.

Analysis about the existing methodology.

To improve existing methods.

Methods to tackle the disadvantages in the current methods.

Design of machine

Fabrication of the designed model

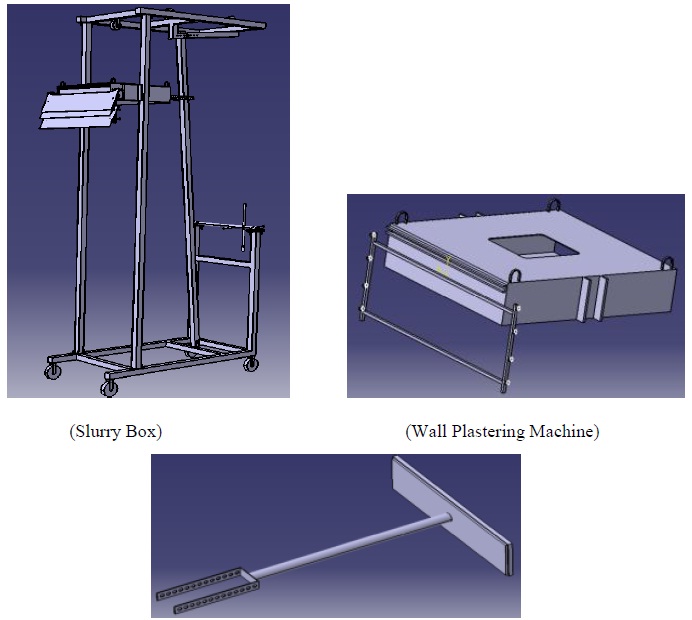

The machine is clamped to the wall ensuring that the blade edges touch the wall surface evenly. The wall-care paste is then poured into the box of the machine which carries the wallcare paste. The inclined column is adjusted to the required inclination angle depending upon the amount of wall-care to be applied on the wall. The box containing the wall-care paste is lowered to the required height. The user then turn on the motor which helps in lifting the box using rope and pulley mechanism? Due to the upward movement of the box the push rod which slides on the inclined column tends to move inwards into the box. The push rod which has a plate and rubber pad at the other end inside the box keeps the box sealed and prevents leakage of the paste. Due to the inward motion of the push rod the pressure is acted upon the paste which moves out from the slit provided on the opposite side of the box, thus enabling the paste to fall on the blade surface. As the blades rest upon the wall surface the upward motion causes the wall-care to be pasted on the wall surface.

Rope drive : 25mm diax0.8m length

0.5HP 3 phase AC motor

Bearing 2No.s

Pulley: 4No.s

Limit Switches : 2No.s

Electric circuit controller

The thickness of the mortar onto the wall achieved manually would vary between 0.5 to 1 inch at different wall conditions, whereas the machine can achieve any thickness constantly and uniformly. It was observed that the wastage was reduced by 0%, while increased mortar thickness increased wastage and also depended on the skill of the labour.

It is time and money saving.

It is more reliable than conventional operation.

It keeps up with the ever changing world of automation.

It increases productivity.

It saves labour and other related cost.

The working conditions, preparation, and raw objects work with are similar to manual rendering.

It is portable, and easy to operate and maintain.

All automated and electronics devices are bound to break down at one time or another. When this happens, a delay towards finishing the job can prove costly and might cause a domino effect on pending jobs. Unlike the basic plastering tools and equipments, which are usually simple one piece manual tools which when damaged can easily be replaced.

It is said that manual labour enhances the expertise and attention to detail of an individual. Some people may say that plastering is more of an art, with plasterers producing magnificent works of art. Being too dependent on automated tools may deter a creative mind and cause loss of interest in the art of plastering.

The present model is semi-automatic and it does not have an automatic loading of mortar. The automation of loading mortar has needed to be carried out.

The machine is developed to do plastering work for straight walls, and not for the construction of a curved walls or inclined walls. Hence Upgrading is possible to make up such challenges.

Further Scope is there for making some changes to use the machine for any size and for the corners and joining of two walls.

The design & fabrication of the Semi-Automated Cement Plastering machine has been successfully completed and tested on different wall surfaces. The result obtained on walls has been considerably smooth finish.

[1] Mahesha P.K, and Sree Rajendra, Design and Fabrication of Automatic Wall Plastering Machine Prototype, IOSR Journal of Mechanical and Civil Engineering, 11(4) 2014, 1-6.

[2] Elattar S.M.S., Automation and robotics in construction: opportunities and challenges, Emirates Journal for Engineering Research, 13 (2) 2008, 21-26.

[3] Quang Ha et al., Robotic Excavation in Construction Automation, IEEE Robotics and Automation Magazine, 2002, 20-28.

[4] Ruchi H., Shortage of Skilled Workers: A Paradox of the Indian Economy, SKOPE Research Paper, 111 2012, 1-30.