Published on Nov 30, 2023

The need for automatic Wheelchair is especially present in care of immovable people (people with persistent vegetative state, paraplegia, stroke and spinal cord injuries), where the care requires a lot of time and manpower. This report is the result of a design and development of an automated multifunctional Wheelchair that would perform all functions present in today’s Wheelchair (Wheelchair with adjustable portion of back rest and leg rest and also convert to bed to wheelchair and vice versa and also remote control with which we can provide all necessary movement) as well as new functions of appropriate Wheelchair sections ( leg positions adjusting). It is expected that this new automatic Wheelchair would enable people’s better medical care, and would greatly reduce time and manpower to the old-age home staff

Wheel chair has become a boon for most of the movement impaired individuals right from its earlier introduction. As time changed the requirement of the wheel chair also changed to make out the needs of different classes of patients. Lots of research has been going on this field and which are aimed at fulfilling these requirements. So many problems are faced by the bed ridden patients sometimes they feel lonely and will be craving for a change in their ambience. Ordinary wheel chair is used by them but this wheel chair moves by manual means. This is where the significance of Automatic wheel chair cum bed arises as this doesn’t require a caretaker. The recent developments in robotics, artificial intelligence and sensor technology promises enormous scope in development of advanced wheel chair. In order to overcome the problems an automatic wheel chair cum bed having adequate features need to be designed. The automatic wheel chair cum bed comprises of a wheel chair which can be converted into a complete bed. Automatic wheel chair cum bed can be controlled by joystick, remote control etc.

A motorized wheel chair or electric-powered wheel chair is a wheel chair that is propelled by means of an electric motor rather than manual power. Motorized wheel chairs are useful for those who are not able to impel a manual wheel chair or who may need to employ a wheel chair for distances or over terrain in a manual wheel chair. They may also be used not just by people with conventional mobility impairments, but also by people with cardiovascular and fatigue based conditions. Electric wheel chairs have enhanced the quality of life for many people with physical disabilities through the mobility they afford The selection of power chair will rely on many factors; including the kind of surface setting the chair will be driven over, the need to settle thresholds and curbs, and clearance widths in accustomed environment. The most fundamental job of the chair is to take input from the user, usually in the form of a small joystick, and to move the person in the preferred direction. The last few years have seen abundant improvements and models that give the user unmatched control of the wheel chair in terms of both user effort and vehicle aptitude

Difficulty in transferring patient to bed from wheel chair.

Uncomfortness felt by the patients when sitting for a long time.

Paraplegic patients.

The objective of this project is to analyze and prototype an automated wheel chair cum bed, based on an existing smart wheel chair with extensive fact findings and research on existing models, technology used, market scenario and customer requirements.

It improves the balance and postural stability of old age people. It can convert sleeping position from sitting position easily.

The course of our work begins with the planning phase involving initial research, literature survey and background study.

It is followed by concept generation phase that includes evaluating existing wheel chair, customer requirements and concept designs.

Prototyping the wheelchair into complete bed using pneumatic system by means of 2-5 bar pressure and we progress towards testing a feasible model.

Collection of all the equipment’s and materials required for overall wheel chair cum bed enhancement setup.

Forming of a light weight wheel chair cum bed structure which would carry up to 80-90 kg.

Successfully coding of a specific program, which would run the device directionally by using joystick, head motion.

Implementation and connection of all the equipments like motors, micro-controller, joystick, accelerometer and other sensors together.

Implementation of pneumatic cylinders, which would converts the Wheel chair into Bed and lifts the wheel chair into adjustable height.

Automatic wheel chair cum bed has a wide range of scope in following areas:

Physically Disabled People can use it as per their purposes. People who are able to use their hand can use Joystick.

People suffering from certain paralysis can use either head movement or Bluetooth module as per requirement.

Patients in the Hospitals

People at old age homes can use this chair as per their requirement

Focusing on mobility assistance for bedridden persons

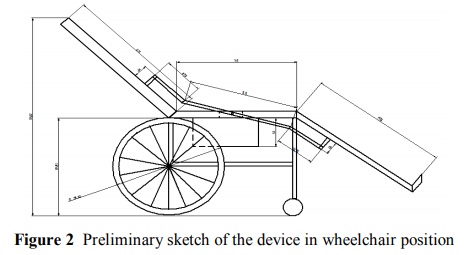

The basic design of the device has evolved from the concept of a convertible wheelchair. Thus the initial sketches for the project design included only the skeletal structure of a wheelchair. Figure 2 Preliminary sketch of the device in wheelchair position Then the convertible feature was included to the design at a conceptual level and tremendous amount of brainstorming was done.

Since the fundamental aim of is to provide comfort to the patient as well as his/her caregiver, powered conversion of the device between chair and stretcher was given focus. In the second phase, the power source was to be selected. Electric motors have good load carrying capacity, speed control characteristics, precision etc.

The material selected must possess the necessary properties for the proposed application. The various requirements to be satisfied can be weight, surface finish, rigidity, ability to withstand environmental attack from chemicals, service life, reliability etc. The following three types of principle properties of materials decisively affect their selection

Physical

Mechanical

From manufacturing point of view

The various physical properties concerned are melting point, thermal Conductivity, specific heat, coefficient of thermal expansion, specific gravity, electrical conductivity, magnetic purposes etc. The various Mechanical properties Concerned are strength in tensile, Compressive shear, bending, torsion and buckling load, fatigue resistance, impact resistance, elastic limit, endurance limit, and modulus of elasticity, hardness, wear resistance and sliding properties. The various properties concerned from the manufacturing point of view are,

Cast ability

Weld ability

Surface properties

Shrinkage

Deep drawing etc.

Sometimes the demand for lowest possible manufacturing cost or surface qualities obtainable by the application of suitable coating substances may demand the use of special materials.

This generally affects the manufacturing process and ultimately the material. For example, it would never be desirable to go casting of a less number of components which can be fabricated much more economically by welding or hand forging the steel.

Some materials may be scarce or in short supply, it then becomes obligatory for the designer to use some other material which though may not be a perfect substitute for the material designed. The delivery of materials and the delivery date of product should also be kept in mind.

Sometimes high strength materials have to be selected because the forces involved are high and space limitations are there.

As in any other problem, in selection of material the cost of material plays an important part and should not be ignored. Sometimes factors like scrap utilization, appearance, and non-maintenance of the designed part are involved in the selection of proper materials

While testing the device, it encountered a problem of height of wheelchair which is not feasible for an average height person. In order to solve the problem the height of wheelchair is reduced from both sides in a proportion to be fit for average height person.

Increase in comfort level of the patient.

Prevents further damage to patients and the helper while transferring him/her from chair to bed or vise-versa.

Patients with serious injuries need not be moved to aggravate their injuries even more.

No special training required to operate them.

Is more efficient than other chairs.

Less costly than electrical version of the same chair.

Increases weight of the chair.

Increases the cost of the chair.

It is used in hospitals.

It can also be used in houses.

We can attach a mini compressor in the wheel chair itself that leads to easy movement and comfortness of the height and bed adjustment of the wheel chair.

Solar panel roof can be used as alternative power source and also it can be a protective layer from rain and sun.

By this system wheelchair will move to the destination given by the patient by using GPS technology. This technology is currently used in driverless cars in various countries.

By using suitable sensors we can predict the nearby objects and that makes the easy movement of the wheel chair.

Controlling wheelchair by electric signal coming from brain. As our brain contains thousands of neuron, there is certain potential difference between each neuron. When we think something neuron emits 0 to 50 HZ electric signal. By interpreting the signal by modulation/demodulation, we can control the chair.

We can control the wheel chair movement by combination of head and voice control system.

The main objective of this product is to make the helper life easy and to make sure the patient is not hurt during the process of treatment. This product eliminates the step of shifting patient from bed or stretcher to wheelchair and vice versa as handling of old age people is very difficult. It makes the patient comfortable when sitting for a long time. This will reduce the effort of the caretaker and provide a safer transfer for the patients in hospitals. . Most modern day technologies use sensors such as accelerometer, gyroscope, to take interactive input and in this project we also have tried to make the robot interactive and close to human. Also we wanted to know about the accelerometer, android app, Joystick, and its working in detail and also wanted to develop a fast and real time project that can help others people. These conditions made Automatic wheel chair cum bed a suitable project for us .Completion of this project needed sheer determination as there were many things that could go wrong. As the electronic circuits meant a lot in this project, creating the programming & circuit proved to be a difficult task being mechanical student. Though some difficulties aroused and many remodeling was needed and the chair had some limitations which we learned while building it, at last the Automatic wheel chair cum bed created very close to the adapted design philosophy.

[1] W.H. J.K. Sunny , K.P. Karunakaran, T. Paul and V. Roy, “Design and Fabrication of Stretcher cum Wheel Chair”, International Journal for Innovative Research in Science and Technology, Vol.2, Issue 11, p p .647-653, April 2016.

[2] S.J. Suryawanshi and K. Janardhan Reddy, “Conceptual Product Development of Wheelchair for People Disabled in Legs”, International Journal of Research in Mechanical Engineering, Vol.1, Issue 2, pp.01-10, OctoberDecember, 2013.

[3] T.J. Alexander B. Martin, J.S.T. Rao and A. Ali, “Development of a Transformable Electrically Powered Wheel Chair into a Medical Emergency Stretcher”, International Journal of Pharmacy and Technology, Vol.8, Issue No.2, June 2016.

[4] J.J. John, J. Johnson, J.C. Joy , G. John and A. Johnson., “Multipurpose Medical Bed”, International Journal of Engineering Research in Mechanical and Civil Engineering, Vol.1, Issue 5, September 2016