Published on Nov 30, 2023

Now a day’s water vending machines are available and operated on only one coin but our aim is to design water vending machine which is operated on different coins. In India there is problem of safe drinking water therefore we are going to provide mineral water. Water has become the most commercial products of the century. This may sound bizarre, but true. The stress on the multiple water resources is a result of a multitude of factors. On the one hand, the rapidly rising population and changing lifestyles have increased the need for fresh water. If opportunity costs were taken into account, it would be clear that in most rural areas, households are paying far more for water supply than the often-normal rates charged in urban areas. Also, if this cost of fetching water which is almost equivalent. To 150 million women days each year, is covered into a loss for the national exchequer, it translates into a whopping 10 billion rupees per year.

The necessity for drinking water may arise irrespective of place. It is highly important to quench the thirst and can become number one priority before any other work. Our project aims on satisfying the public with its need for drinking water at any random place like bus stops, shopping centres or even street side by designing and fabricating a “Portable Water Vending Machine”.

Our further implications apart from reducing the size includes a massive reduction in capital investment of the machine in comparison with the Water Vending Machines installed byIndian Railway and Tourism Corporation at nine different locations across the country.

The machine is a result of integration of Mechanical and Electronic concepts to bring about a compact product. It would occupy space not more than 2x2ft. on the ground. It provides portable water at equal costs to that of the Water Vending Machines of the Indian Railway and Tourism Corporation. Also, the capital costs will be reduced 20x times in comparison to the prior.

1. To provide purified drinking water.

2. To provide portable water at economical cost.

3. To develop modelling and simulation.

4. To design and fabricate a portable machine using simple techniques.

5. To adopt simple design mechanism that can be easily maintained.

6. To make use of existing pre-purified water bottles (20lts can) as refills for vending machine.

7. To encourage local Entrepreneurs.

8. To extend drinking water facility for common public.

The present condition of water availability is scarce. So, it is important to use it in required amount only.

The quantity of plastic wasted in packing drinking water is very high, i.e. 50 billion bottles per year in U.S alone. Among that only 10% gets recycled. So, when 20lts bottles are widely used, usage of small plastic bottles is reduced

The existing Water Vending Machine is an expensive machine that costs 2.5-3 lakhs.

The IRTC Water Vending Machine Occupies a large space of about 6x6x8ft.

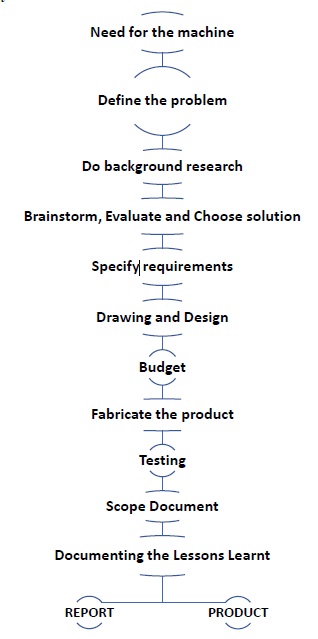

In order to reduce cost of Pre purified drinking water and make it available at all places an problem is stated as to design and fabricate Sugar Powdering Machine Using Structured Product Design Approach.

Designing of the product is carried out in CatiaV5.

The electronic components used are –

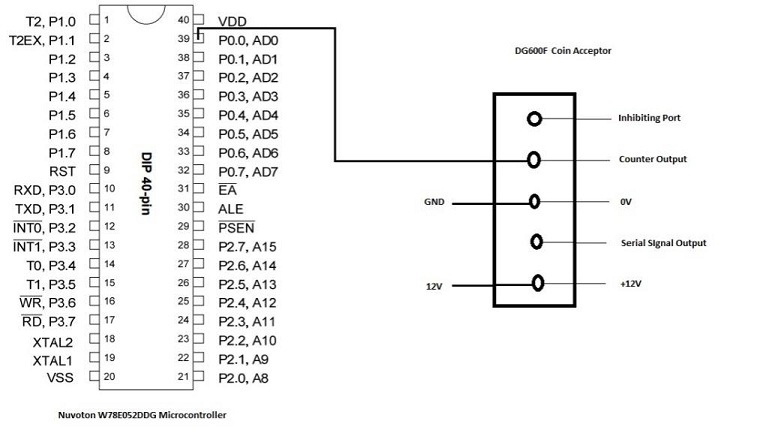

A. Coin Acceptor (DG600F)

B. Development Board: 89V51RD2 Flasher Board

C. Microcontroller – Nuvoton W78E052DDG

D. Direct Operated Water Solenoid Valve

E. L293D

F. L293D Dual H-Bridge DC Motor Driver Module for 8051

G. 12V 1.2AH Rechargeable Battery

Materials Used for Fabrication are –

A. Stainless Steel Sheet Metal for container

B. Cast Iron for stand

Interfacing:

A. Interfacing DG600F and Nuvoton W78E052DDG

The 20lts Bisleri water can cost RS 70 in the market. So, the 20,000ml in the bottle can be divided by more than 70 times for a profitable trade, i.e. when the machine is programmed for anything less than 285ml per RS 1, it becomes a profit to the vendor/machine owner.

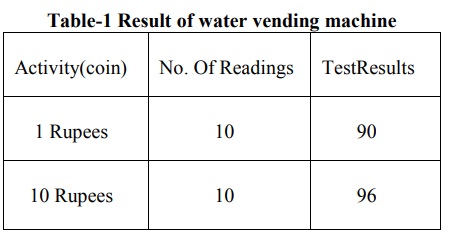

The set objectives i.e. to develop a compact and a portable water vending machine is designed and constructed.Which uses 20lts per purified water bottles as refill. This product when installed in public places it satisfies the drinking water needs of the public.

Low design time.

Low production cost.

This system is applicable for both the indoor and outdoor environment.

Conservation of space

Safe

Cost Effective

Clean Space

Low power consumption.

Various Indian as well as multinational companies such as Sarvajal, DJB-Tata Power, Amrutdhara Water Services Pvt. Ltd etc. are involved in this business. They currently provide drinking water to people in the range of 15 paisa to 1 rupee per liter on a pilot basis. we will replace the wired network installed in the machine by a wireless network to remove the complex indoor wiring and provide the easy installation of sensor .we will install more sensors such as humidity, temperature, dust, and smell.

Implementation of Coin-Operated Automatic Drinking Water Machine is the step towards the future technology and it is a step to enter in eco-friendly world. This machine is easy to use and can be easily accessed by the ordinary person. This proposed system can be implemented almost everywhere even in the remote sensing areas and the places where there is water crises. This system is most suitable in trains because it takes less space and in each bogie of train we can place it easily. It will also help in reducing the diseases which are being spread because of using contaminated or unhygienic water by people.

[1] P. Pradeepa, T. Sudhalavanya, K. Suganthi, N. Suganthi, M. Menagadevi [2013],“Design and Implementation of vending machine using Verilog HDL”, International Journal of Advanced Engineering Technology, Vol. IV, Issue I, E-ISSN 0976-3945, pp. 51-53.2.

[2] M.S.Varadarajan [2012], “Coin Based Universal Mobile Battery Charger Veltech”,IOSR Journal of Engineering (IOSRJEN), Volume 2, Issue 6, and ISSN: 2250

[3] Manas Kumar Parai, Banasree Das, Gautam Das [2013], “An Overview of microcontroller Unit: From proper selection to Specific Application”, International Journal of Soft Computing and Engineering (IJSCE), Volume 2, Issue 6, and ISSN: 2231-2307, pp 28-31.

[4] Kerry segrava(12 july 2002), vending machines: An American Social History Mcfarland, ISBN 978-0-7864- 8159-0