Published on Nov 30, 2023

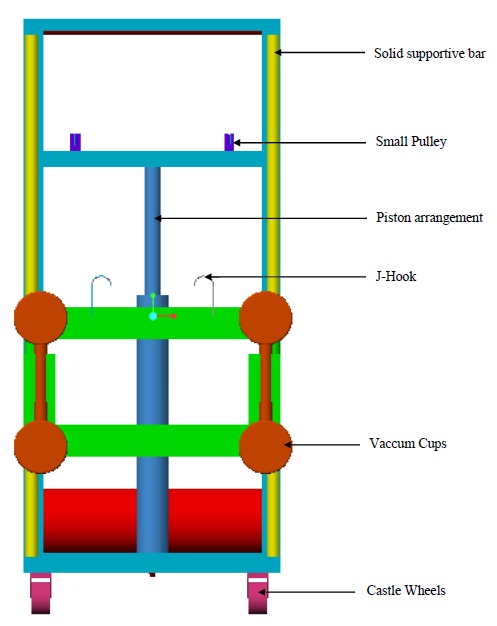

Comfort coupled with safety and simplicity is what man strives for. Our project has been to bring about both .The culmination of our effort has resulted in development of a new “Design & Fabrication of Multipurpose Material Handling Machine”. The project present a basic as well as very professional treatment of the subject in a very comprehensive, based on learning effort and understanding capability of today as per their levels. The device is simple and comfortable. Basic calculation, drawing, designing is included in the project The salient features of our machine can be listed as the mechanism used is very simple, easy for operation; no skill is required to operate the machine. Hydraulic cylinders are used at high pressures and produce large forces and precise movement. For this reason they are constructed of strong materials such as steel and designed to withstand large forces. Because gas is an expansive substance, it is dangerous to use pneumatic cylinders at high pressures so they are limited to about 10 bar pressure. Consequently they are constructed from lighter materials such as aluminum and brass. Because gas is a compressible substance, the motion of a pneumatic cylinder is hard to control precisely.

The device affords plenty of scope for modifications, further improvements & operational efficiency, which should make it commercially available & attractive. If taken up for commercial production and marketed properly, we are sure it will be accepted in the industry. Cylinders are linear actuators which convert fluid power into mechanical power. They are also known as JACKS or RAMS. Hydraulic cylinders are used at high pressures and produce large forces and precise movement. For this reason they are constructed of strong materials such as steel and designed to withstand large forces. Because gas is an expansive substance, it is dangerous to use pneumatic cylinders at high pressures so they are limited to about 10 bar pressure.

Consequently they are constructed from lighter materials such as aluminum and brass. Because gas is a compressible substance, the motion of a pneumatic cylinder is hard to control precisely. The basic theory for hydraulic and pneumatic cylinders is otherwise the same. Material handling equipment is mechanical equipment used for the movement, storage, control and protection of materials, goods and products throughout the process of manufacturing, distribution, consumption and disposal. The different types of handling equipment can be classified into four major categories. Transport equipment, positioning equipment, unit load formation equipment, and storage equipment.The major subcategories of transport equipment are conveyors, cranes, and industrial trucks. Material can also be transported manually using no equipment

1. To make a complete mechanical device: The idea is to make a device which does not use any electrical power so that it is fully independent of its electricity.

2. To make a device which is suitable economical for small Scale industries: taking in to consideration the cost factor this device is suitable for small scale as well as large scale industries.

3. Taking safety as a prime consideration: This device is safer in all aspects.

4. To build a device which can do various operations like glass handling and fork lift.

1. Collected the information about the raw materials to be used in the project.

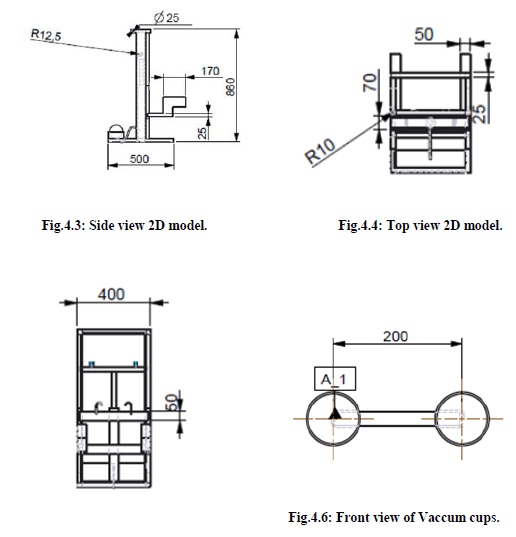

2. Design of the machine using Solid Works 9.0.

3. Collection of the spare parts.

4. Building of frame work and assembly of parts.

5. The result of machine verified and noted down.

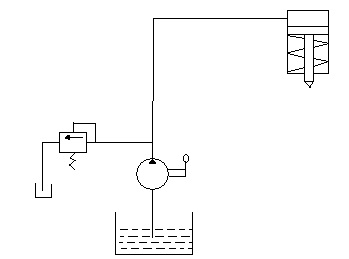

Oil Circulation is there through all components as per hydraulic circuit, here we are Appling the pressure with the help of a handle and it works according to the Pascal law this machine does the work of lifting the glass well as fork lift this machine is used to lift glass, and any plane object

Consideration in Machine Design When a machine is to be designed the following points to be considered: -

i) Types of load and stresses caused by the load.

ii) Motion of the parts and kinematics of machine. This deals with the type of motion i.e. reciprocating. Rotary and oscillatory.

iii) Selection of material & factors like strength, durability, weight, corrosion resistant, weld ability, machine ability are considered.

iv) Form and size of the components.

v) Frictional resistances and ease of lubrication.

vi) Convince and economical in operation.

vii) Use of standard parts.

viii) Facilities available for manufacturing.

ix) Cost of making the machine.

x) Numbers of machine or product are manufactured.

1) Easy in operation.

2) Low cost

3) Simple construction.

4) Adaptable.

5) High capacity.

6) Performance.

7) Manually operated.

8) Environmental friendly.

9) Easy to setup

1. Use to handle glass, from one place to another.

2. Use to position tiles on the floor.

3. Used as a fork lift in industry to carry goods in the plant

4. Used to lift tiles, glass or we can say any flat object with good surface finish

We feel the project that we have done has a good future scope in any engineering industry. The main constraint of this device is the high initial cost but has low operating costs. Savings resulting from the use of this device will make it pay for itself with in short period of time & it can be a great companion in any engineering industry dealing with rusted and unused metals. The device affords plenty of scope for modifications, further improvements & operational efficiency, which should make it commercially available & attractive. If taken up for commercial production and marketed properly, we are sure it will be accepted in the industry. It has plenty of scope if the device is made larger in size so that the capacity of shearing the metals is more and it can be used in the factory premises.

1) The Purpose is to make a machine which does not use any electrical power so that it is fully independent of electricity.

2) Mainly the design was made to lift 100 kg but in practical it lifted 80 kg.

3) Biggest challenge is vaccum cup alignment with high suction force.

4) Maneuverability of device is good and handling of device is simple.

5) Future application like traverse movement of the sleeve where it cannot be reached manually

[1] Pantazopoulos G, Vazdirvanidis A. ―Fractographic and metallographic study of spalling failure of steel straightener rolls‖. Journal of Failure Analysis and Prevention 2008;8(6):509–14.

[2] Pantazopoulos G, Vazdirvanidis A, Toulfatzis A, Rikos A. ―Fatigue failure of steel links operating as chain links in a heavy duty draw bench‖. Engineering Failure Analysis 2009;16(7):2440–9.

[3] Figueiredo MV,et al. ―Analysis of a heavy duty lift truck. Engineering Failure Analysis‖ 2001;8:411–21

[4] Sachs NW. ―Understanding the surface features of fatigue fractures: how they describe the failure cause and the failure history‖. Journal of Failure Analysis and Prevention 2005;5(2):11–5.