Published on Nov 30, 2023

The world is presently confronted with a lot of health issues even having modern sophisticated technologies. Blood pressure, Kidney stones, Mal nourishment, Gallbladder diseases are the major and unavoidable health issues as on today irrespective of age group. In this regard there is a lot of scope to search for solutions which are feasible and promising better health. In this view organic coconut products namely Virgin coconut oil, Tender coconut mint cooler, Tender coconut green chilly cooler and Tender coconut tea will give the harmonic health benefits for the human being. From the exhaustive literature associated with human health issues it has given constructive hopes to have healthier life with inventing identical solution. Hence the project is aimed to design, development and fabrication of machine to resolve the health issues with some extent. The new approach with sincere effort may give positive signs towards healthier life for human kind.

The defined objectives of the project are not only for health aspects, it will also encourage the coconut formers, unskilled people and unemployed people to have their own jobs with good profit in turn their annual economy.

The tender coconut water(TCW) and virgin coconut oil(VCO) are recommendable to the people of almost every age. They have high nutritional value and most of the doctors recommend both tender coconut water and virgin coconut oil to their patients. The calorie and the sugar content of tender coconut water is also very low. So it does not have any bad effect on human health. It acts as tonic that reduces the fatigue in an instant. The tender coconut water is considered as the healthiest drink because of its high vitamin and protein content. VCO is also considered unique in the sense that it is the only oil with multi-functional uses: It is the only oil which one can eat as a food supplement or functional food, use for cooking, apply to the hair and skin as a moisturizer and conditioner, and use as a major ingredient in skin care products or as carrier oil in aromatherapy and massage oils

. On an average, street hawker sells at about 100 green coconuts per day. The conventional way of cutting the coconut is done by the sharp knife and the task is done by the expertise and anybody cannot do it. In the conventional way, cutting the top portion of the coconut and the time required for the operation is more than 1 Minute. Hence the waiting time for the customer is more and attraction of the customer is less. Now a day the process of chopping the green coconut is very tedious and chances of causing the accident are more. Utmost care and skill is required to chop the coconut in traditional way. To compare “our invention” with traditional method, ours is safest. Today the industrial sector in India is hit badly due to lack of power and improper management in small scale production. This is the basic reason for the developing a virgin coconut oil extraction machine.

Extraction machine refers both to manual and economically as a mode of daily commuting aspects as well as the use of virgin oil in a commercial activity, which is the natural oil obtained from fresh coconut by various extraction methods as well as being efficient in operation and durable. In this project fabrication of virgin oil extraction machine using simple designs and mechanism is carried out.

Our main objective is to fabricate a low-cost hydraulic coconut punching and shearing machine for tender coconut in which we punch the hole and cut the coconut into two halves and ready to sell the coconut to customer and anyone can chop and have a sip of coconut water and with the same machine we can also extract the virgin coconut oil(VCO) from the matured coconut.

The world is presently confronted with a lot of health issues even having modern sophisticated technologies. Blood pressure, Kidney stones, Mal nourishment, Gallbladder diseases are the major and unavoidable health issues as on today irrespective of age group. In this regard there is a lot of scope to search for solutions which are feasible and promising better health. In this view organic coconut products namely Virgin coconut oil, Tender coconut mint cooler, Tender coconut green chilly cooler and Tender coconut tea will give the harmonic health benefits for the human being. From the exhaustive literature associated with human health issues had given constructive hopes to have healthier life with inventing identical solution. Hence project aimed to design, development and fabrication of machine to resolve the health issues with some extent. The new approach with sincere effort may give positive signs towards healthier life for human kind.

The following objectives are framed with constructive hopes, however these objectives are not only for health aspects, it will also encourage the coconut formers, unskilled people and unemployed people to have their own jobs with good profit in turn their annual economy.

To design, development and fabrication of tender coconut and matured coconut processing unit.

To prepare tender coconut based organic products.

Extraction of virgin coconut oil from newly designed tender coconut and matured coconut processing unit.

Assessment of cost and profit of the produced coconut based products.

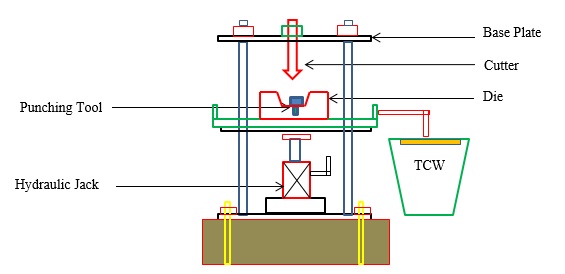

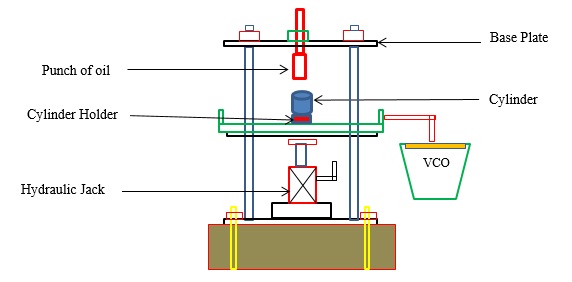

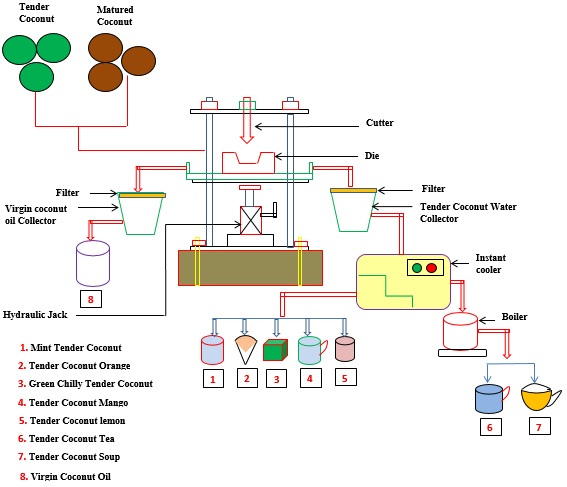

The tender coconut and matured coconuts will be used to extract the tender coconut water and virgin coconut oil respectively. Tender coconut and matured coconut processing unit was designed using solid edge software and drafted drawings are considered for fabrication of machine. Designed machine is planned to fabricate with food grade SS 304 material as per ASTM standards. In the first step, tender coconut water will be taken from the extracting machine then it is passed to instant cooler to retain its original properties. Similarly in the second step, virgin coconut oil will be extract from the same machine followed by filtration later produced TCW and VCW will be processed and tested as per ASTM standards to have various health benefit products.Fig.7 show the schematic representation of extracting TCW from tender coconut.Fig.8 shows the schematic representation of extracting VCO from the matured coconut by replacing cutter and punching tool by punch and cylinder.Fig.9 shows the overall process of our project work.

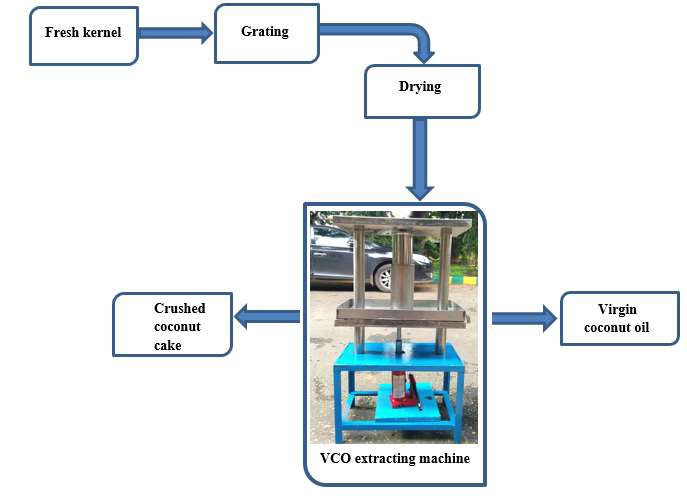

After drying the coconut powder, the Virgin coconut oil is extracted from the dried powder by using VCO extracting machine. The machine is operated with the hydraulic jack of capacity 5ton.The Fig.16 shows the overall process flow of VCO extraction.

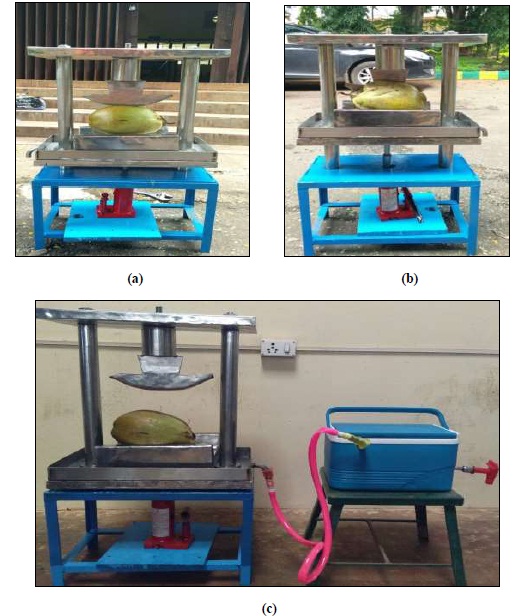

The model of TCW and VCO extracting machine is fabricated as per the design drawings shown in the chapter 5. The fig.20 and fig.21 shows the pictures of the fabricated model of TCW and VCO extracting machine respectively.

Fabricated model of TCW extracting machine (a) Initial stage of extracting TCW in the fabricated model (b) Working stage of extracting TCW in the fabricated model (c) Complete TCW extracting plant photo

The fabrication and calculation related to mechanism as well as bill of material has been carried out for coconut water extraction machine. The total system is divided into two units:

Power input to hydraulic jack: Effort is applied to hydraulic jack lever by hand.

Power input to machine: Power is inputted to machine by hydraulic jack.

Output of machine: punch the hole in coconut and splitting of coconut into two parts.

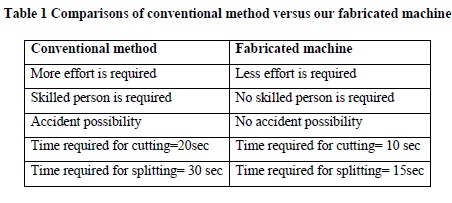

The comparison of conventional method of extracting TCW and extracting of TCW by our fabricated machine is shown in the below table 1.

The defined project with newly designed processing unit may support and provide the organic based products to the people of the nation with no adulterants. In this aspect unskilled people can also make the business with newly designed processing unit as machine operation is simple and with fewer penalties on time. The higher benefits in health and economy can be archived by producing various coconut products in larger quantities with designed processing unit. The coconut based products production will be the key solution to improve the coconut growers’ economy followed by nation economy with providing empowerment for the rural people.

1) The project carried out by us is helpful for street hawkers and make the task easier for them.

2) This project greatly reduced the operation time as compared to conventional method.

3) By the implementation of this machine new entrepreneur can easily purchase and start his or her business.

4) This machine is mainly design to cut the coconut and to make the hole in coconut with the help of various tools like cutting blade, hole making tool. The important thing about this machine is that it reduces the time of cutting the coconut, along with the coconut the various fruits can be cut out on these machines.

5) The two operations can be done simultaneously there is no any extra attachment is required for performing the operations. The cost of the developed machine is very less so that it can be used in small restaurants and shops. This will definitely improve the productivity of coconut in all parts of the country and various new applications can be generated in future.

[1] Manisha DebMandal, Shyamapada Mandal” Coconut (Cocos nucifera L.: Arecaceae): In health promotion and disease prevention”,Asian Pacific journal of tropical medicine.

[2] Edward Chan and Craig Elevitch “Cocos Nucifera(coconut) Arecaceae(palm family)”,Species profile of Pacific Island Agroforestry,April 2006,ver. 2. 1.

[3] T. Roshni, J. Jippu, C. S. Ratheesh, J. Sachin and K. L. Sreevisakh “Development of a Household Coconut Punch-cum-Splitter”, Agricultural Engineering International: the CIGR Ejournal. Manuscript 1188. Vol. XI. May, 2009.

[4] S. Yahya and I. Mohd Zainal “Design and performance of young coconut shaping machine” J. Trop. Agric. and Fd. Sc. 42(1) (2014): 19 – 28.