Published on Nov 30, 2023

Bio- Diesel can also prepared from fruit seed oil to Diesel Engines .Mamey Sapote seeds are easily available and nonedible to all human being. Since most of the biodiesel were derived from edible oils like soybean, sunflower, rapeseed, palm etc. these oils are essentially edible in India and other developing countries and use in biodiesel leads to food crisis. Because of the non-edible oil having high free fatty acid (FFA) content, which is not suitable for normal transesterification process, hence a two-step catalyzed method was adopted to prepare the biodiesel. In the present investigation Mamey Sapote seed oil was used to extract the biodiesel. Therefore, this research mainly concentrates the non-edible oil as a feed stock for biodiesel production to reduce the cost of bio-diesel.

The results showed that this bio-fuel can be produced at a yield of 92.48 % with a 0.760% of catalyst, 6 methanol equivalents in excess with respect to oil, at 60°C, and 90 min of reaction time. Biodiesel from Mamey Sapote seed oil is mainly composed of methyl esters of oleic, stearic and palmitic acids. Hence could be considered as a suitable substitute for fossil diesel in unmodified diesel engine applications.

Fossil fuels are currently the dominant global source of CO2 emissions and their combustion is stronger threat to the environment. Increasing of the industrialization, energy demand, limited reserves of fossil fuels and increasing environmental pollution have jointly necessitating the exploring of some alternative to the conventional liquid fuels, vegetable oils (edible and non edible oil) have been considered as appropriate alternatives to the conventional liquid fuels, vegetable oils have been considered as appropriate alternative due to their prevalent fuel properties. It was thought of as feasible option quite earlier. However despite the technical feasibility, vegetable oils as fuel could not get acceptance, as they were more expensive than petroleum fuels.

This led to the retardation in scientific efforts to investigate the further acceptability of vegetable oils as alternate fuels. Later, due to numerous factors as stated above created resumed interest of researchers in vegetable oils as substitute fuel for diesel engines. In view of the potential properties, large number of investigation has been carried out internationally in the area of vegetable oils as alternate fuels. Some of the vegetable oils from farm and forest origin have been identified. India imports the petroleum products at an annual cost of 50 billion USD in the year 2012- 2013.Just by replacing 5% of petroleum fuel by bio fuel could enable India to save 2.5 billion USD. According to latest documents from April 2013-Feb 2014 got an import of 57335.97 million USD but from April 2014-Feb 2015 got an import of 53739.04 million USD. We come to know that the demand of import of petroleum products decreased by 6.27%.

Scientific Name : ManilkaraZapota

Availability : India, South Florida , Pakistan , Bangladesh , Thailand , Central America

Chemical Composition of Sapota : Sugars , Proteins and Minerals like Iron , Copper , Calcium and Potassium

ManilkaraZapota Tree - It is a medium seized evergreen tree. It grows upto 8-15m. Bears fruit when it is 4-5 years and attains stability in production. Leaves used for medicine.

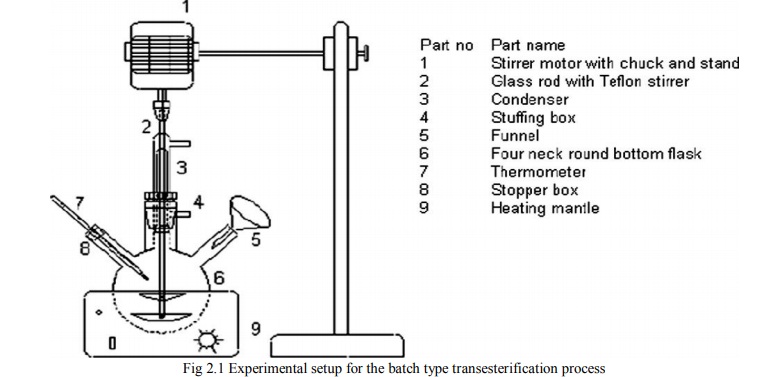

Mamey Sapote seeds were collected and pure analytical grade methanol and potassium hydroxide (KOH) in pellet form of were used for the biodiesel production. Only seeds that were not damaged were chosen and stored under cool dry storage conditions until needed .The experimental setup consists of a half liter four-necked batch type spherical glass reactor, with a water-cooled condenser in one of the necks, a speed controlled mechanical stirrer, and a temperature controlled heating mantle and a thermometer. The collected seeds were dried and moisture content is eliminated from the seeds. After that by using Mechanical screw pressing machine raw oil was extracted from the dry seeds. The oil was filtered and dried; the collected oil was approximately 25% of raw seeds. The various properties of oil like density, viscosity, flash point were estimated from the various instruments as per the ASTM standards. The arrangement of the batch type transesterification reactor used in the study is shown in Fig. 1.

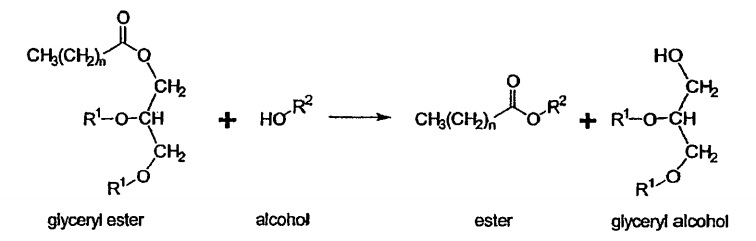

The non-edible oils having high FFA content, which is not suitable for normal transesterification process. If the FFA content of the oil is less than 2.5%, then one step transesterification process with a base catalyst should be used and if it exceeds 2.5%, two step transesterification process should be the choice. In this study as the FFA content of MSO was 3.26%, single step base catalyst transesterification method has been adopted. In the present analysis the following parameters are chosen for the production of biodiesel.

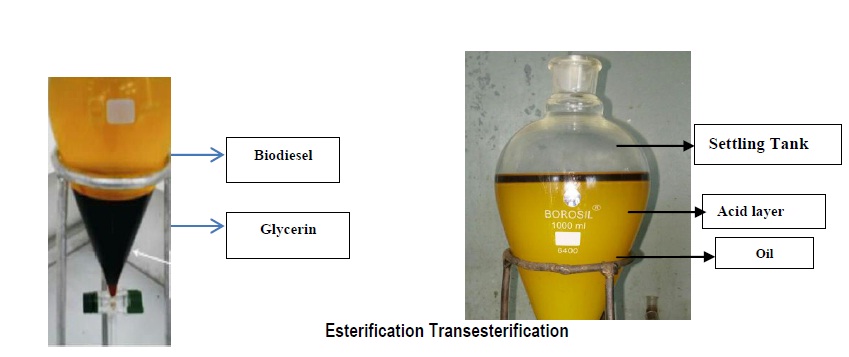

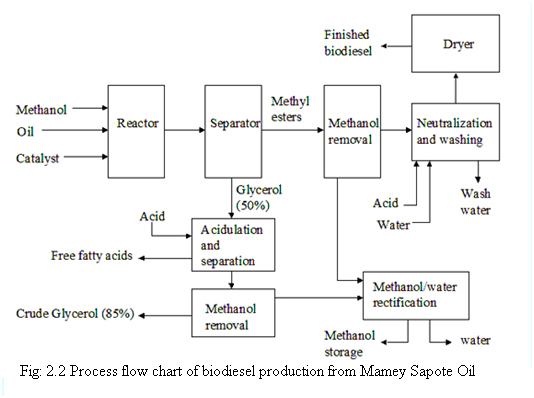

In a batch reactor Mamey Sapota oil of 100 gm was placed and heated it up to 60º C temperature The stirrer speed was maintained at 500 rpm for constant mixing. The methoxide solution was prepared by dissolving the exactly measured quantity of solid catalyst (KOH) in premeasured quantity of methanol. Once the oil reached the up to 60º C temperature, the prepared methoxide was slowly poured into the reactor. The completion of pouring instant was taken as the start of reaction. The condenser was installed on one of the four necks to capture and reuse any vaporized methanol. Upon reaching the predefined time of reaction, the reactor was taken out of the heating mantle and the products of the reaction were shifted to a 500 ml separating conical funnel. After 24 h of settling, the heavy glycerol layer settled at the bottom of the funnel was removed through a drainage valve. The remaining crude biodiesel produced from MSO was gently washed with distilled water at 40 ºC in order to remove the un reacted methanol, catalysts and impurities. The percentage yield of biodiesel has been calculated using the formula

Biodiesel yield % Y = (grams of methyl ester produced / grams of oil used in reaction) X 100

After transesterification, the ester layer may contain un reacted catalyst, methanol and residual glycerol. These impurities were removed by warm water treatment. During the washing process, gentle agitation is required to avoid the emulsion. After separation of the layer for 30 min, the wash water layer was drained off from the bottom of the separating funnel. The water washing method was continued (2-3 times) until the water layer becomes clear. For this process, equal amount of hot distilled water was used to remove the impurities.

After the completion of purification process, the ester layer may contain some amount of water and methanol. This should be removed because methanol reduces the flash point of fuel and it has corrosive nature to fuel hoses. Water content is responsible for the growth of biological organisms and it increases the acid value of fuel. Hence the ester layer was subjected to distillation at 100°C for 15 to 30 min to remove the water and methanol content present in the product (biodiesel). Final biodiesel product after purification is obtained acid catalyzed transesterification followed by alkaline catalyzed transesterification. Finally, the biodiesel fuel was saved for further analysis

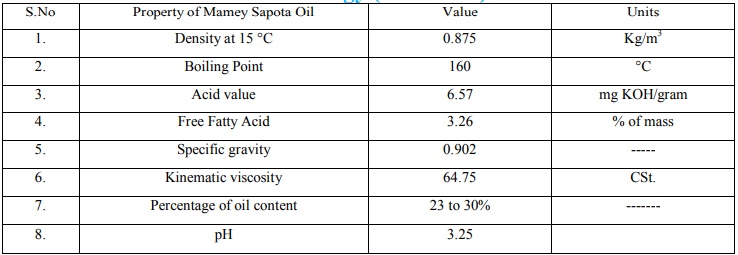

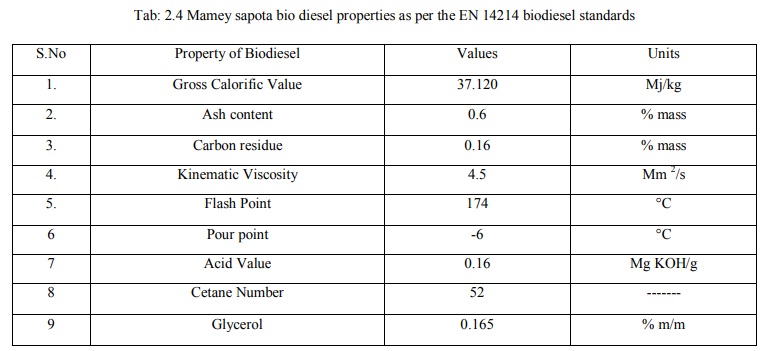

In the present investigation crude Mamey Sapota oil has been used for the production of biodiesel and its physicochemical properties and fatty acid composition have been studied to find the suitability as feed stock for biodiesel production. Based on its properties and fatty acid content, suitable production process was selected. Table 2.2 shows the composition and the percentage weight content of different types of saturated and unsaturated fatty acids of MSO. The highest content of unsaturated fatty acid was found to be oleic acid (64.62%) and the next one was linoleic acid (17.78%). Palmitic acid tops the list with saturated fatty acid content. The total unsaturated and saturated fatty acid content of MSO was found to be 84. 13% and 15.87% respectively. Major properties of Mamey Sapote namely density, viscosity, acid value, peroxide value, heating value, pour point, flash point pH, and cetane number were estimated using ASTM standards and reported in Table 2.3. The results show that all the properties of MZME are meeting the requirements of EN14214 biodiesel standards and hence MZME could be a potential substitute to petro diesel.

Some aspects are identified with the present work, and are presented below.

Biodiesel production technology needs further study in the aspects of elimination of biodiesel purification process by using newly developed heterogeneous base catalyst like, Zeolites, MgO and ZnOetc instead of homogeneous catalyst (H2SO4&NaOH).

The properties of blend may be further improved to make use of higher percentage of Manilkara Zapota oil in the blend by preheating the blend.

Further study of low volatility of Manilkara Zapota oil need to be investigated to know the effect on engine.

MZOME satisfies the important fuel properties as per ASTM specification of Biodiesel.

The existing petro-diesel engine performs satisfactorily on biodiesel fuel without any significant engine modifications.

Most of the major exhaust pollutants such as HC are reduced with the use of biodiesel and the blend as compared to petro-diesel.

But NOX emissions increase when fuelled with petro-diesel. Biodiesel fuel blends as compared to petro-diesel fuel. This is one of the major drawbacks of biodiesel.

[1] Wu Xuan, Leung Dennis YC. Optimization of biodiesel production from Camelina oil using orthogonal experiment. Appl Energy 2011;88(11):3615–24.

[2] Karabas Hulya. Biodiesel production from crude acorn (Quercus frainetto L.) kernel oil: an optimisation process using the Taguchi method. Renew Energy 2013;53:384–8.

[3] Sureshkumar K, Velraj R, Ganesan R. Performance and exhaust emission characteristics of a CI engine fueled with Pongamia pinnata methyl ester (PPME) and its blends with diesel. Renew Energy 2008;33(10):2294–302.

[4] Sathish Kumar R, Suresh Kumar K. Effect of methanol blending with Pongamia pinnata biodiesel and diesel blends on engine performance and exhaust emission characteristics of an unmodified compression ignition engine. Ambient Energy doi: 10.1080/01430750.2013.823108.