Published on Nov 30, 2023

Many nations and regions all over the world are facing severe threats on water scarcities or deprivation of the water environment resulting from issues such as hot-headed population growth, rising living standards carried about by economic progress and growing use of industrial water. And also as, availability of safe drinking water and water for the agricultural purposes are increasingly becoming the most challenging issues of our country, water conservation and utilization plans along with integrated understanding of all these issues is most importantly required. By keeping the following things in mind, this waste water treatment system is designed and developed specifically for the coir industries of country (As Kerala/India is one of the major producers of coir in the world after Sri Lanka) in order to provide a very simple and affordable way of purification our of contaminated water produced after a series of chemical processes (including retting and soaking).

Coir has faced a declining market for traditional products in recent decades. Despite their comparatively low trade value, the fibres provide significant economic support to populations in specific areas of the producing countries (for example, in the southern Indian states of Kerala, Karnataka, Tamil Nadu and Andhra Pradesh, and in west and south Sri Lanka). Women in these areas are particularly dependent on coir production for their livelihood. Traditionally, coir has been processed into a range of products such as yarns for the production of floor coverings, mats and matting, cordage and nets, bristle fibres for brooms and brushes, and for use with domestic mattress and upholstery industries. These markets have been dwindling in recent years due to strong competition from synthetic products. However, there is a firm trend in the industrial countries towards the production and use of more environmentally benign products and systems, which may help to mitigate the adverse ecological affects of current production methods.

The effects of chemical industries, atmospheric degradation, global warming, fast-declining natural resource base, deforestation, waste production, pollution and similar global issues have increased the demand for environmentally benign products. Renewable raw materials such as plant fibres and products, therefore, may have good market perspectives if they can be produced at an economically competitive price and on a scale where quality and supply can be guaranteed3 Currently, expanding export markets for coir can be seen in the demand for erosion control mats and other geotextile applications for civil engineering, or in the demand from the automotive and mattress industries for rubberised coir pads4 .

The main motto of this project is to provide industrial automation in order to clean the industrial effluents (Exhausts) and also to recycle the water for further use due to which the environmental/water pollution can be very effectively reduced and the treated water can be in turn used for many other domestic purposes and is cost effective as well.

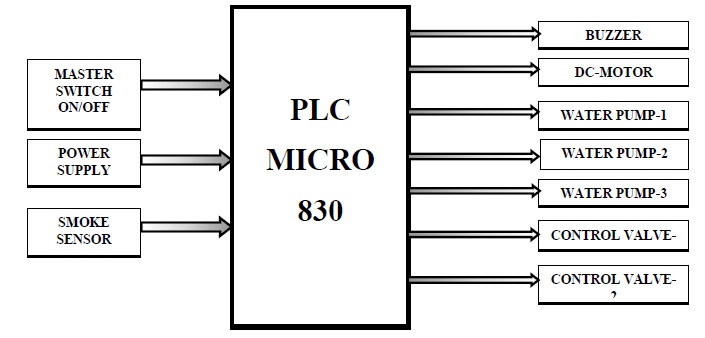

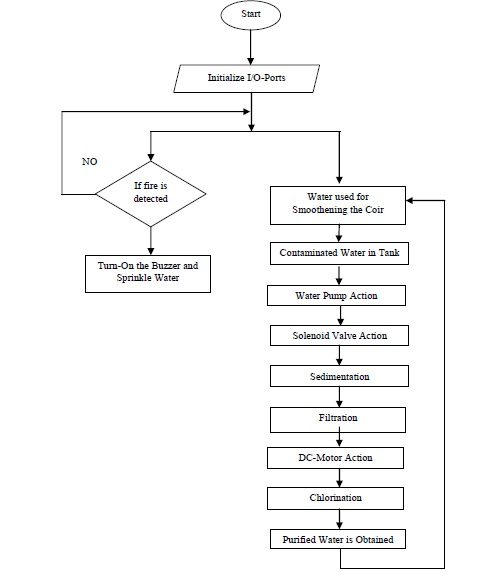

Figure-1 depicts the simple outline of the system hardware. The proposed work includes inputs, outputs, hardware and PLC. The input consists of reservoir tanks, power supply, smoke sensor and master switch ON/OFF. The output consists of DC motors, control valves, water pumps and buzzer. The reservoir tank consists of the waste water to be treated. The water pump is controlled by PLC, which pumps the water through a mesh to filter macro particle like sand, stones etc. The next stage consists of the filter membrane which filter minute or dissolved particle present in the water followed by the chlorination process. The solenoid valves open and close according to the controlling action of PLC to allow the water treatment in different stages. Send back the treated water to the small scale industries, apartment and also can be recycled for horticultural activities. This treated water is delivered

to the small scale industries or apartments one after the other for some predefined length of time which is handled by the embedded timer in the PLC. This process of waste water treatment keeps on repeating until it is switched off externally trough manual assistance.

The Components of the Automated System are as follows:

It provides the supply current to the device in order to activate the device and to provide energy for its operation. This supply is derived from Domestic AC Mains rated at 230v /50 Hz, which is further rectified to Pure DC within the PLC-system.

It serves as the main switch to switch ON and OFF the complete Automated System through a single button.

Smoke sensor MQ7 identifies the nearness of carbon monoxide within air and it reads the output of the analogue voltage at fixations from 10 to 10,000 ppm. Only one analogue input pin from PLC micro 830 required sensor’s simple analogue voltage for the purpose of interface. The smoke sensor used here is MQ7. This MQ7 sensor is suitable for a wide range of applications and is available at a reasonable market cost.

It is nothing but a loud speaker used to produce loud alarm signals to indicate if there is any fire/smoke indications around/inside the systems surroundings to the operator.

In this system 12V solenoid valve using as a control valve. A solenoid control valve working as a electromechanically. This 12V solenoid valve is controlled by an electric current through a solenoid valve. These are utilized to stop, discharge, and measurements and circulate liquids. These valves give minimized configuration, safe and quick operating, great medium similarity of the materials utilized, long administration life, low control power and high unwavering quality.

The DC-motor is being controlled by PLC micro 830. In this system a 5V DC-motor is employed. It is used to operate the stirrer. The DC-motor belongs to the class of electrical machines that proselytes electrical force produced by the direct current into mechanical force. The DC-motor’s velocity can be controlled over a wide range, by either changing the quality of current in its field windings or by varying the supply voltage.

In this system using a 6V DC water pump for pumping water into the tank when water level in the tank reduces to low level and turn off on filling of water to maximum level.

The programmable logic controller is characterized as a computerized electronic gadget to execute capacities and to store direction. For example: sequencing, rationale, timing and math operations to control machines, procedures and numbering and also to control the succession of operations. In this framework PLC is controlling the input parameters like sensors, power supply and output parameters like water pump, solenoid valves, DC motors. Programmable logic controller i.e. the input or output character is like that of an electromagnetic pneumatic valve controller or relay. In the electronic memory the program/code will be stored. The advanced PLCs of latest designs have increased timer and counter capabilities along with advanced features such as performance analysis and optimizations. The PLC version employed as a part of this framework is micro-830. Everything is by all accounts more exact, solid and more proficient because of PLCs.

The designed model demonstrates the automated waste water treatment process for coir industry by utilizing Programmable logic controller micro 830 and 24V power supply. The PLC set up depends on which device utilizing as a part of the procedure. At the end of procedure purified water passed to the industry. The treatment of contaminated water can be done with this proposed work, this waste water treatment plant clean up the small scale industry effluents. So, treated water can be recycled for further use. Thus, purified water is recycled and stored. It has great importance in small and large scale industries as well as in society. The waste water treatment of this system is treated depending on the type of industries.

The proposed project is useful for purification of wastewater in coir industry, it can be future developed for large scale industries, residencies or apartment and also for drinking purpose.

Although some additional mechanisation has been introduced for fibre extraction, and novel accelerated retting technologies have recently been shown to offer substantial improvements over existing practices, the general approach to existing systems of production remain unchanged. Retting continues to pollute surface waters, and working conditions for people remain unhealthy. Existing mechanical defibration procedures and equipment are extremely dangerous, even for skilled workers, and fingers and hands continue to be lost. People, however, continue to work with this equipment within antiquated industrial systems. Costs of alternative technologies are high, and have generally not been introduced. R&D costs are equally high, and funds are difficult to raise for this traditional fibre commodity, since earnings from fibre production remain marginal. The majority of fibre producers operate on a small-scale at a village level and are unable to contribute towards the costs of R&D programmes. The public sector may need to provide for industrial continuity, and also to encourage traders and others to develop and exploit novel markets that could provide a measure of security for smallholders and small-scale processors.

1. FAO (1990, 1993). Production Yearbook, nos 44 and 47, and FAO On-line statistical data base, http://apps.fao.org/

2. Steele, P.E. (1997), Coconut industries development and the importance of technical innovation, Technical Seminar, Allepey, December.

3. van Dam, J.E.G., G.E.T. van Vilsteren, F.H.A. Zomers, I.T. Hamilton and B.Shannon. (1994). Industrial Fibre Crops. Study on increased application of domestically produced plant fibres in textiles, pulp and paper production and composite materials. European Commission: (EC DGXII - EUR 16101 EN).

4. Chand, V. (1995). Market development and promotion of selected coconut husk products from India and Sri Lanka. Report of CFC Project ITC/DPMD/95/257.