Published on Nov 30, 2023

With the increasing population day by day the focus on effective and agricultural methods is getting more attention. The technological advancements are used to required scale in industrial sector, but agricultural sector still uses obsolete methods. Thus with this as a major area of concern, this project deals with the development of wireless dual control solar powered smart insecticide and fertilizer spraying machine to help Farmers. The proposed machine should be able to spray insecticides pesticides and fertilizers using a tank provided onto the machine. The dual mode control permits the control of machine using remote controller. In addition the proposed machine should have the ability to adjust the height of spraying for different crops.

Keywords: Wireless, spraying, height etc.

Day by day the population of India is increasing and to fulfill the need of food modernization of agricultural sectors are important. Due to chemical fertilizers the fertility of soil is decreasing. Hence farmers are attracted towards organic farming. By mechanization in spraying devices fertilizers and pesticides are distributed equally on the farm and reduce the quantity of waste, which results in prevention of losses and wastage of input applied to farm. It will reduce the cost of production. It will reduce the cost of production. Mechanization gives higher productivity in minimum input. Farmers are using same traditional methods for spraying fertilizers and pesticides. Conventionally the spraying is done by labors carrying backpack sprayer and fertilizers are sprayed manually.

They are doing seed sowing, fertilizers and pesticides spraying, cultivating by conventional methods. There is need of development in this sector and most commonly on fertilizers pesticides spraying technique, because it requires more efforts and time to spray by traditional way. To solve these problems this project deals with the development of dual mode solar powered insecticide and fertilizer spraying machine.

The following research papers were referred before starting with the project. The excerpt form our study is documented in the literature review. It consists of research work carried out by the research scholars.

1. LaukikP.Raut, Smith B.Jaiswal, NitinY.Mohite[1] worked on Design, development and fabrication of agricultural pesticides sprayer with weeder.

2. Prof. Swati D.Kale, Swati V. Khandagale, Shweta S. Gaikwad [2], developed Agriculture Drone for Spraying fertilizer and pesticides.

3. S.R.Kulkarni, Harish Nayak, Mohan Futane [3], developed portable foot operated Agricultural Fertilizer and pesticides spraying pump.

In this entire course of project our major objective is to change the obsolete methods being currently followed in Indian agriculture systems. The objectives of the project are outlined as below:

To design a machine which can carry a pesticide/fertilizer spraying tank on it and can be move across the fields.

To add the ability to change the height of spraying using liner traversing mechanisms, this can enable the developed machine to spray at different heights for different crops.

To construct this machine in such a way that it can travel across any type of terrain.

To make this machine solar powered, so that it can be readily charges using the energy received from the sun.

By meeting all these objectives we plan to develop a complete solution conventional spraying which is usually done manually. The project easily be implemented in any type of field and can be used for spraying any type of crops as the machine is also equipped electronic spray height adjustment system. Further the machine implements dual mode control.

The methodology for carrying out the project is divided into following phases.

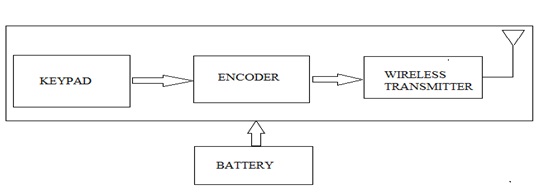

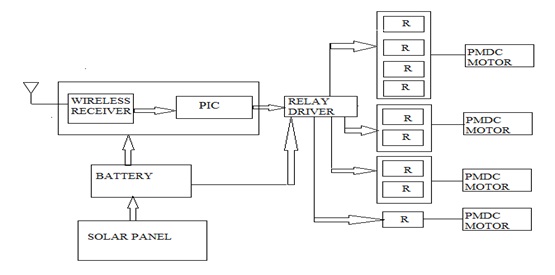

The mechanical fabrication involves the fabrication of the frame onto which all the other components will be mounted. The frame consists of 4 wheels which are used for navigation of the frame and it is fabricated in such a way that it can hold all the components properly in a balance manner. After the frame is fabricated it is equipped with DC geared motors of high torque which can help to move the frame based on signals received from the microcontroller.

After the Frame the pesticide tank will be incorporated onto the machine which be used to store the fertilizers and pesticides. The tank is equipped with a high pressure pump which will pump the liquid from tank and spray it.

The microcontroller is selected in this phase. The microcontroller selection plays an important role. In this phase the microcontroller selected is interfaced with motors using the motors drivers for direction control.

To make the machine to be used for crops of larger height such as sugarcane and also smaller height ex. Chickpea, this phase involves incorporating the machine with mechanisms which can be used to adjust height of the sprayer. The system is mechanical system which can be controller using signals from microcontroller, which drive the actuators connected onto the system.

In this phase finally the machine is incorporated with a solar panel which can be used to provide all the energy to the machine.

In this phase the difference components are assembled to make a full fledged machine.

This is the final phase of the project in which the machine is tested and optimized for performance.

We have designed a machine which can carry a pesticide/fertilizer spraying tank on it and can move across the fields. It has ability to move sprayer up and down by remote. We haveconstructed robot in such a way that it can travel across any type of terrain. We have added solar panel, so that it can be readily charge using the energy received from the sun and it also reduces the cost of battery.

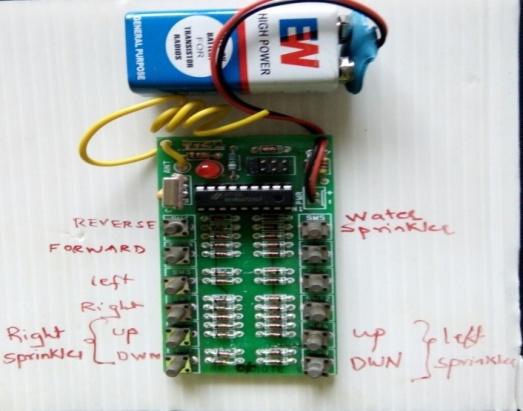

Robot prototype

1. Wireless operation will eliminate the health issues and would even save them from tedious work.

2. It will have less use of manpower.

3. Efficient and health conscious operation due to remote sensing.

4. With the help of live feed of spraying the farmer is expected to control the robot wirelessly from a distant place.

5. This Robot is expected to be an all terrain robot.

1. During the rainy season the sloppiness would reduce the speed of the robot.

2. All the electronics components mounted on the chassis need to be covered properly else environmental changes could alter the output.

3. The system is bulky.

1. Robot can be used for monitoring using the wireless camera and FPV

2. To Interface the developed machine with the android device, to provide android control to the machine over the Bluetooth.

3. SMS based system to start and stop the service

4. Preprogrammed GUI based navigation system

5. Android interface to navigate the robot

6. Programming based on crop type and amount.

In the very early years the fields were cleared of weeds and prepared for planting by hand at great effort, using primitive hoes or digging sticks. The invention of the plough was started about 6,000 years ago and it was a great labor-saving device for humans - the beginning of systematic substitution of other forms of energy, in this case animal power, in replacement of human muscles. In india after the independence the demand of food increased drastically and in order to meet the heavy demand of food the farmers had to increase the productivity of the crops so that they can be made market ready as fast as possible.To meet this need the farmers had to use more amount of fertilizers. Fertilizers are mainly classified as organic and inorganic fertilizers. The organic fertilizers (animal wastes and plant residues) must be broken down into inorganic forms in the soil before plants can take up the nutrients required for growth and reproduction. They are relatively inefficient because they contain low concentrations of nutrients and hence, large volumes of material need to be transported and spread over fields to overcome deficiencies.

1. LaukikP.Raut, Smith B.Jaiswal, NitinY.Mohite, “Design, development and fabrication of agriculturalpesticides sprayer with weeder”,International journal of applied Research and studies,ISSN:2278-9480volume2,Issue 11(Nov-2013)

2. Prof. Swati D.Kale, Swati V. Khandagale, Shweta S. Gaikwad, “Agriculture Drone for Spraying fertilizerand pesticides”, International journal of advance research in computer science and software Engineering,volume 5,Issue 12,(Dec-2015)

3. S.R.Kulkarni, Harish Nayak, Mohan Futane, “Fabrication of portable foot operated Agricultural Fertilizerand pesticides spraying pump, International journal of Engineering Research and technology,ISSN:2278-0181,volume 4 ,Issue 07(July-2015)

4. Sandip H. Poratkar, Dhanraj R. Raut, “Development of multi-nozzle pesticide sprayer pump, International journal of Modern Engineering Research, ISSN: 2249-6645, volume 3, Issue 2, pp-864-868, (April-2013)