Published on Nov 30, 2023

The present rate of economic growth is unsustainable without saving of fossil energy like crude oil, natural gas, or coal. There are many alternatives to fossil energy such as biomass, hydropower, and wind energy. Also, suitable waste management strategy is another important aspect. Development and modernization have brought about a huge increase in the production of all kinds of commodities, which indirectly generate waste. Plastics have been one of the materials because of their wide range of applications due to versatility and relatively low cost. Some 299 million tons of plastics were produced in 2013, representing a 4 percent increase over 2012. Recovery and recycling, however, remain insufficient, and millions of tons of plastics end up in landfills and oceans each year Approximately 10–20 million tons of plastic end up in the oceans each year. A recent study conservatively estimated that 5.25 trillion plastic particles weighing a total of 268,940 tons are currently floating in the world’s oceans. And since plastic being a non-biodegradable material it remains into the soil, thereby polluting the environment.

Our Project deals with the extraction of OIL/DIESEL from the waste plastics termed as PLASTIC PYROLYZED OIL which can be marketed at much cheaper rates compared to that present in the market.

As we know that both Plastics and Petroleum derived fuels are Hydrocarbons that contain the elements of Carbon & Hydrogen. Pyrolysis process becomes an option of waste-to-energy technology to deliver bio-fuel to replace fossil fuel. The advantage of the pyrolysis process is its ability to handle unsort and dirty plastic. The pre-treatment of the material is easy. Plastic is needed to be sorted and dried. Pyrolysis is also non toxic or non environmental harmful emission unlike incineration.

Keywords : Waste Plastic, Pyrolyzed Oil

The main objectives of this project are:

1. To establish the basis for the development and implementation of waste plastics recycling with the application of environmentally sound technologies (EST) to promote resource conservation and green house gases (GHG).

2.To raise awareness in developing countries like INDIA on plastic waste and its possible reuse for conversion into diesel or fuel, this could be generated and marketed at cheaper rates compared to that of the available diesel or oil in the market.

3. To reduce the dependency on gulf countries for fossil fuels, thereby contributing to the Economic growth of the country.

1. Identification of waste plastics. (PE/PP/PS/LDPE/HDPE)

2. Subjecting the waste plastic for pyrolysis process.

3. Condensation of the gas to obtain raw fuel.

4. Conversion of raw fuel into its pure form (diesel etc) by the process of distillation.

The collection of waste plastic is quite an easy task as compared to other wastes , the plastic wastes are abundant and can be obtained in large quantities from the households, roadsides, hospitals, hotels etc.

This plastics are usually termed as

POLYETHYLENE (PE)

POLYPROPYLENE (PP)

HIGH DENSITY POLYETHYLENE (HDPE)

LOW DENSITY POLYETHYLENE (LDPE)

Usually they are manufactured in the form of plastic bags, saline bottles, plastic tools, chairs and other components which we usually come across in our day to day life.These plastics could be collected or usually purchased at Rs.10 to 15/kg after being shredded and washed properly.

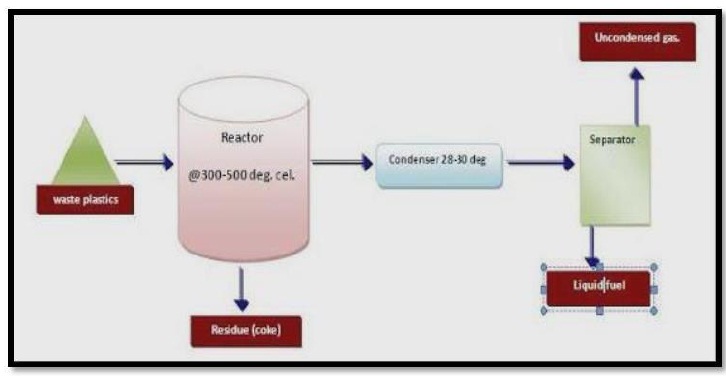

The pyrolysis is a simple process in which the organic matter is subjected to higher temperature about 300ºC to 500ºC in order to promote thermal cracking of the organic matter so as to obtain the end products in the form of – liquid, char and gas in absence of oxygen.

Comparison of Green House Gas (GHG) Emissions by Pyrolysis process with other processes:

Emissions associated with manufacture of other raw materials (excluding the waste plastic stream) are 13.0kgCO2. For the case of pyrolysis these are owing to hydrogen that is consumed within the process.

Site emissions from incineration of pyrolysis gases, distillation residues and 3% of the diesel product generated are 56kgCO2

Emissions associated with all elements of transport (products and waste) are 197kgCO2

Based on these figures the emissions associated with pyrolysis are 266kgCO2

Displacement savings associated with replacing fossilised diesel production are 426kgCO2.

Overall the net emissions for pyrolysis are –160kgCO2.

Experimental setup of trial test conducted, wherein 380 grams of plastic was dumped into a closed container and heated.

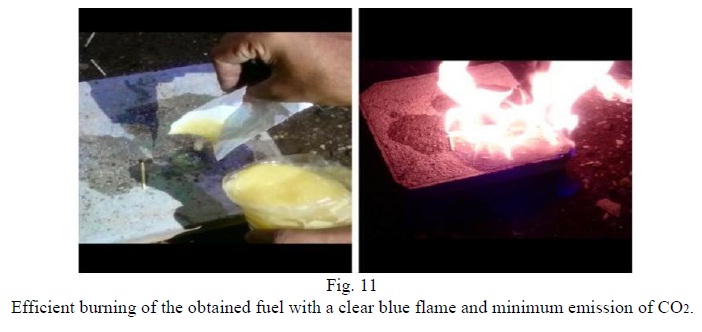

Semi liquid fuel obtained after burning the waste plastic, which can be further processed into diesel.

Efficient burning of the obtained fuel with a clear blue flame and minimum emission of CO2.

The below picture shows the mould prepared by us so as to serve as a pyrolyzer device.

1.The obtained fuel could be utilized in diesel generators, vehicles such as tractors and also passenger vehicles such as cars.

2. The fuel has to be refined at the industrial establishments, based on the results of which small scale industry can be established.

3. As there is a high demand of crude oil and due to its sky reaching prices , we could take up this project to setup large or small scale industries and produce the fuel locally at much cheaper rates directly benefiting the National economy and also a step towards SWAACH BHARAT by recycling the waste plastic.

4. The application of this project could help in reducing the dependency on the gulf countries and promote a step towards innovation.

1. Through our experimentation we concluded that about 600 to 750ml of diesel fuel could be obtained by burning 1Kg of plastic. Burning 1Kg of plastic in an open environment produces 3Kg of CO2, whereas by converting it into fuel and burning it reduces 80% of CO2 emissions , which results in to be quite environmentally friendly.

2. Lesser emission of unburnt HYDROCARBONS in waste plastic pyrolysis oil compared to that of diesel.

3. The diesel or oil thus obtained has a higher efficiency with around 30 to 40% low production cost compared to that available in the market.

It is very difficult to find out alternative of plastic. Even plastic´s demand is increasing every day as well as their waste. This project analysis has observed the use of waste plastics, a factory planning and its feasibility in Metropolitan City. It is easily assumed that, when the use of waste plastic will increase then the solid waste management will search more ways to find out to collect them. The implementation of this project can develop so many opportunities in the city. It can be a solution to control waste plastic, develop a new technique or idea, and detect the source of diesel for the country. Bangladesh is such a country where this kind of project could be very promising and effective in the future The use of plastic pyrolysis oil in diesel engine in the aspect of technical and economical is compared and found that oil is able to replace the diesel oil.Though the plastic pyrolysis oil offers lower engine performance, the plastic waste amount is enormous and it needed to be process to reduce the environmental problems. Moreover, the engine can be modify follow the combustion condition of plastic pyrolysis oil. The waste plastic used in the process must be PE or PP or LDPE in order to protect the contamination of chlorine in the oil.

1. J. Walendziewski, Engine fuel derived from plastics by thermal treatment, fuel 81 (2002) 473-481

2. M. Mani, G. NagarajaN, Influence of injection timing on performance, emission and combustion characteristics of a DI diesel engine running on waste plastic oil Energy 34 (2009) 1617–1623

3. F. Murphy, K. M. Donnell, E. Butler, G. Devlin, The evaluation of viscosity and density of blends ofCyn-diesel pyrolysis fuel with conventional diesel fuel in relation to compliance with fuel specifications EN 590:2009.

4. N. Miskolczi, A. Angyal, L. Bartha, I. Valkai, Fuels by pyrolysis of waste plastics from agricultural and packaging sectors in a pilot scale reactor Fuel Processing Technology 90 (2009) 1032 –104