Published on Nov 30, 2023

Concrete is a composite material composed of coarse aggregate bonded together with fluid cement that hardens over time. Most concretes used are lime-based concretes such as Portland cement concrete or concretes made with other hydraulic cements. However, asphalt concrete, which is frequently used for road surfaces, is also a type of concrete, where the cement material is bitumen, and polymer concretes are sometimes used where the cementing material is a polymer.

When aggregate is mixed together with dry Portland cement and water, the mixture forms a fluid mass that is easily moulded into shape. The cement reacts chemically with the water and other ingredients to form a hard matrix that binds the materials together into a durable stone-like material that has many uses. Often, additives (such as pozzolans or super plasticizers) are included in the mixture to improve the physical properties of the wet mix or the finished material. Most concrete is poured with reinforcing materials embedded to provide tensile strength, yielding reinforced concrete.

There is a growing trend of considering water reuse as an essential component of water resources management and sustainable development, not only in dry and water deficient areas, but in water abundant regions as well. Some examples of successful water reuse projects are the use of reclaimed water in place of potable water for use in irrigation, environmental restoration, cleaning, toilet flushing, and industrial uses. It has been shown that the basis for the success of such projects are operational performance, institutional arrangements, conservative cost and sales estimates, and good project communication, avoiding institutional obstacles, inadequate valuation of economic benefits, or a lack of public information.

Keywords : Concrete, reinforced concrete, Portland cement, Wash Water

The main objective is to cast & study the harden properties of concrete using STP treated & Untreated wash water.

The specific objectives are:

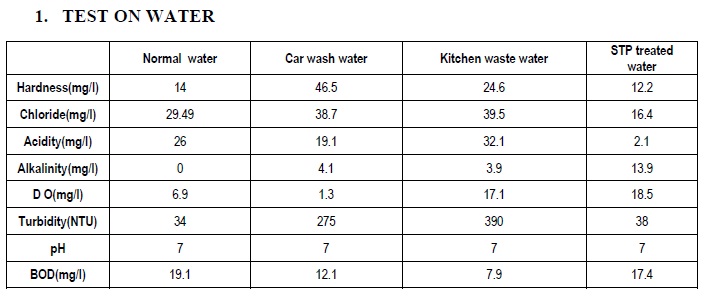

1. Property & tests on water (Treated & Untreated)

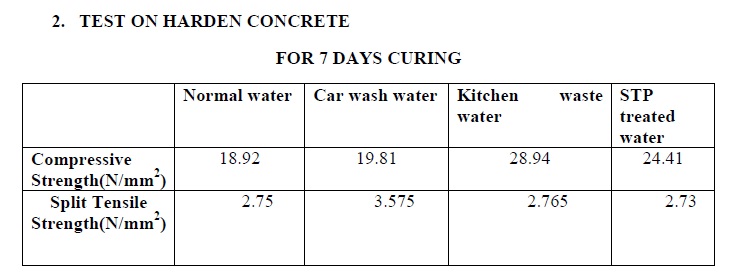

2. Study of strength properties of the concrete casted with STP treated & untreated wash water.

Materials

Cement is a binder, a substance that sets and hardens as the cement dries and also reacts with carbon dioxide in the air dependently, and can bind other materials together. Portland cement is the most common type of cement in general use around the world, used as a basic ingredient of concrete, mortar, stucco, and most no specialty grout.

Aggregate of size less than 2.36 mm is measured as fine aggregate. The quantity of fineness less than 0.12 mm is to be measured as fine particles. A small amount quantity of fines must be used to reduce separation. The zone of fine aggregate is determined by sieve analysis.

Crush granite aggregate available from local sources has been used. The coarse aggregate with maximum size of 12mm having the specific gravity value of 2.6 and fineness modulus of 5.60 were used as a coarse aggregate.

Water Water has main functions in a concrete mix; it serves as a lubricant in the mixture of fine aggregates and cement.

Sewage treatment is the process of removing contaminants from wastewater, primarily from household sewage. It includes physical, chemical, and biological processes to remove these contaminants and produce environmentally safe treated wastewater (or treated effluent). A by-product of sewage treatment is usually a semi-solid waste or slurry, called sewage sludge, which has to undergo further treatment before being suitable for disposal or land application. Sewage treatment may also be referred to as wastewater treatment, although the latter is a broader term which can also be applied to purely industrial wastewater. For most cities, the sewer system will also carry a proportion of industrial effluent to the sewage treatment plant which has usually received pre-treatment at the factories themselves to reduce the pollutant load. If the sewer system is a combined sewer then it will also carry urban runoff (storm water) to the sewage treatment plant.

Sullage or untreated wash water is all wastewater generated in households or office buildings from streams without fecal contamination, i.e. all streams except for the wastewater from toilets. Sources of wash water include, e.g. sinks, showers, baths, clothes washing machines or dish washers & car washing. As wash water contains fewer pathogens than domestic wastewater, it is generally safer to handle and easier to treat and other non-potable uses.

Methodology:

A mould of rectangular cross section of size 150mm x 150mm x 150mm is made with wood or steel also cylindrical mould of size 150mm dia x 300mm height. Make the required size of rectangular & cylindrical mould from wood or tin. Place the clay or mud in the sides where the optical fibers are exposed to the mould for the easy de-moulding after the concreting.

The thoroughly mixed concrete is poured carefully and slowly without causing many disturbances to the previously laid optical fibers. The concrete is filled in smaller or thinner layers and is agitated with the help of vibrating tables to avoid the void formation.

After 24 hours, remove the mould and pull off the mud. The casted mould was kept undisturbed on the leveled platform. Then it was de-moulded carefully after 24 hours from casting immediately after de-moulding, the cube specimens were marked by their respective identification mark/numbers.

Expected Outcome of the project: Harden property of concrete using STP treated and untreated wash water.

Application of the project: Any concreting work. Reuse of previously used water and replacement of potable water which helps in environment causes.