Published on Nov 30, 2023

Until a few decades ago water pollution used to be primarily a local problem with identifiable sources of pollution. Most of the wastes came from human and animal excreta and other biogenic compounds. Many of these problems could be controlled by treatment plants and alternative technologies. However, over the years the increasing gross pollution load of the receiving waters and its complex character have resulted in a situation which calls for radical change in our approach to save this precious resource.

Wastewater discharges from a paper mill contains solids nutrients and dissolved organic matter such as lignin. It also contains alcohol, and chelating agents and inorganic materials like chlorates and transition metal compounds the waste water from paper mills has generally low Bio-degradability due to the presence of recalcitrant compound. The problem of water pollution is one such havoc that has taken the attention of scientists and social activists all around the globe. The main problem with the waste water is its generation in larger quantity with higher organic loads and serious pollution potentials. Therefore, problem of waste water disposal continues to be a serious threat in present as well as in nearby future.

Keywords : HRT, Up-flow Anaerobic Bioreactor, pH, Chlorides, TS, TSS, COD, BOD.

1. To study the performance of the up flow fixed bed Anaerobic bioreactor along with quarry dust filter for pollutant removal from paper mill effluent at different Hydraulic Retention Time (HRT).

2. To reduce the contaminants in waste water by alternate treatment method.

3. Reduction of effluent parameters to meet the CPCB standards.

4. To obtain the maximum efficiency of filters in pollutant removal.

To study the pollutant removal efficiency at different hydraulic retention time (HRT), a hybrid anaerobic up flow fixed-bed bio reactor combined with Quarry Dust Filter is fabricated. The bio reactor has an internal diameter of 36cm, height 48.5cm and volume of 49 litres. The Quarry filter attached with bio reactor has additional volume of 20 L. The anaerobic bio filter has an inlet 5cm and an outlet at a height of 40cm from base. A Gas outlet at the top of up flow fixed- bed bioreactor is also provided for the release of gases produced during anaerobic treatment.

The Anaerobic upflow fixed-bed bioreactor consists of Pall rings (2.5-3.8cm diameter) as support material. Pall rings act as support for naturally Self immobilization slim

layer formed by anaerobic microbes. Immobilization of microbial cells has received increasing interest in the field of waste treatment and offers advantages such as high bio mass, high metabolic activity and strong resistance to toxic chemicals. Moreover, immobilized microorganisms are cost effective and can be used several times without significant loss of activity in Anaerobic Bioreactors. Effluent moved in a vertical Up flow mode, thus got maximum contact time with slime and got treated while moving Upward in the Bioreactor.

The Quarry filter attached to Bioreactor has Quarry dust particle between the range of 1.7 and 2mm. This Quarry dust is passed sieve opening 2mm and retained on sieve opening 1.7mm, hence eliminating particles above and below this range. The selected quarry dust particles are then washed to remove the Clay and Organic matter adhering to them.

Acclimatization is the process in which microbial species or Organisms adjust and adapt themselves to new environmental factors (such as Altitude , temperature, humidity) over time.

1. Bioreactor is kept for 6weeks for acclimatization period.

2. The effluent to be fed in the bioreactor for acclimatization is especially prepared.

3. 1 kg of fresh settled sludge from the effluent treatment plant of pulp and paper mill, 1litre of cow dung slurry, 4.5gm of KMnO4 to fix free oxygen and 200gm of Nutrient broth media mixed with 10 litre of effluent and are filtered with 2mm sieve.

4. This solution is placed in well sieved fixed Up flow bioreactor at HRT of 3days.

5. At the interval of 3 days 20% of the acclimatizing feed is drained out of the biofilter and replaced by pulp and paper mill waste water.

6. In bio-filter draining out of effluent is done through additionally attached Quarry dust filter.

7. The replacement of drained feed by fresh effluent is repeated periodically at the interval of 3 days till 6 weeks of acclimatization.

Anaerobic fixed-bed is an energy efficient process used for the treatment of waste containing high concentration of biodegradable organic material. It involves a series of degradation and fermentation reactions carried out by various prokaryotes to digest suspended solids and large macromolecules into soluble components .These products are further fermented by the cooperative actions of syntrophic bacteria to produce acetate, carbon dioxide and H2 and finally broken down by methanogenic Archaea to produce methane and CO2.

Quarry dust filter is one of the most efficient processes improving the physical ,biological and chemical quality of water .It relies on both physical and as well biological approach for waste treatment .Wastewater particles larger than the Quarry dust particles are easily strained out and retained within the filter making it one of the most efficient process for improving the quality of wastewater .The most striking advantages of Quarry dust filter involve its reuse ,low energy requirement, tolerance of seasonal input fluxes and do not require lengthy start-up and shutdown periods.

Keeping in view the benefits of microbial degradation Quarry dust filter is used in combination with up flow fixed- bed anaerobic bioreactor for the treatment of pulp and paper mill effluent. From economical and operational point of view, biological treatment is energy efficient way of treating biodegradable waste water and this in combination with Quarry dust filter with effective size 0.15-0.3mm provide wide passage for treated water that increases removal efficiency range by 99-99.9%.

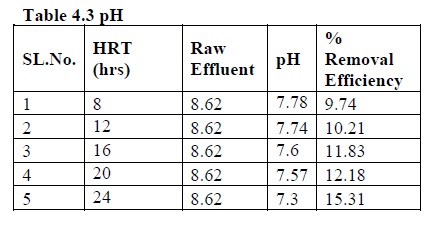

After the period of 6 weeks of acclimatization period, it is supposed that the active growth of bacteria has lead sufficient slime cover around the packing media (polypropylene pall rings) in the bioreactor. Before actual setup of bioreactor, new effluent is fed in bioreactor replacing continuously the effluent at a HRT of 16 hours to give a good reactor startup and adapt the microorganisms for new feed, for continuous and efficient operation. After a week of effluent flow in the bioreactors, the results are analyzed at different HTR of 8, 12, 16, 20 and 24hours. The HRT is calculated as follows:

HRT = Volume of biofilter / Effluent flow rate

SI unit of volume is in (m3) and effluent flow rate is in (m3/hr). HRT is usually expressed in hours or days. Hence, HRT is maintained by adjusting the flow rate of the effluent, such that it spends desired time inside the bioreactor. The reduction is measured by analyzing different physico-chemical parameter in triplicate from each bio filter. The mean value of the replicate bio filter setup is taken for further calculations.

Hardware Requirements: Acrylic sheets, polypropylene pall rings, acrylic pipes, taps.

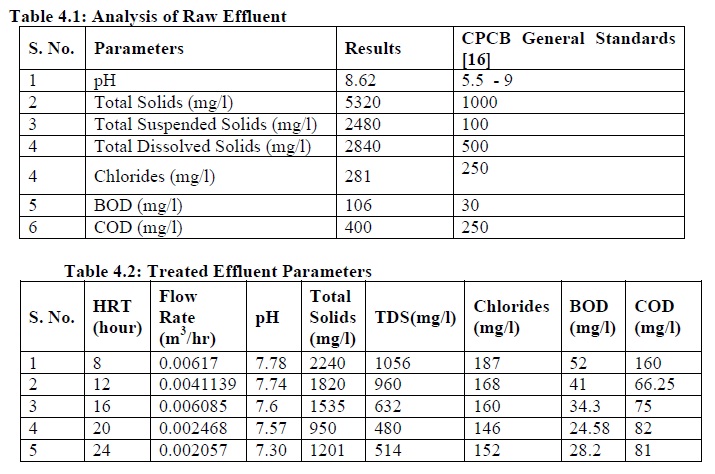

The pulp and paper mill effluent was found to be alkaline in nature with pH value of 8.1. Apart from high BOD and COD, the effluent also contained high total solids and suspended solids, quite higher than permissible limits as prescribed in CPCB for discharge of wastewater in inland water bodies. Table 4.1 shows the result obtained for raw paper and pulp mill effluent.

Sand filters have been mostly used a low cost treatment methods as alternative to septic tank/soil absorption systems for domestic wastewater. However, their use for treatment of industrial wastewater with high pollutant removal efficiency is achieved when it is attached to upflow fixed bed bioreactor.

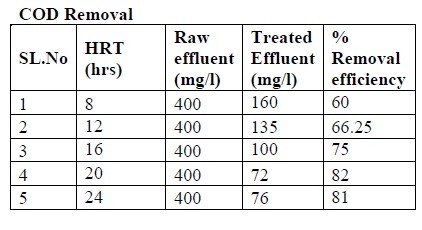

The pH of the effluent was initially 8.6; the values attained a constant pH of 7.6 to 7.3 at a HRT of 16 hours as shown in fig.4.1. The methanogenic phase could start efficiently at much lower time as methanogens need a neutral pH to work, and as soon as this pH is attained, degradation starts.

From fig.4.4 It is evident that at initial 8 hour HRT, the BOD removal efficiency is 51%, with increase in HRT, performance also increases linearly to 76.8% for 20 hr. Further increase in HRT reduced the performance to 73.4 % making it almost parallel to x axis, which symbolizes stationary phase or the maximum removal capacity of bio filters.

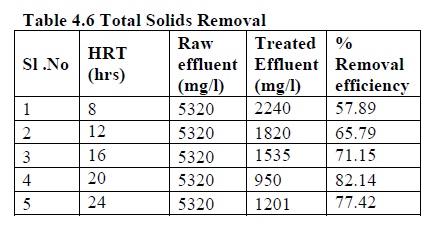

Similarly in case of COD at 8 hr HRT, the bio filters showed pollutant removal of 60%, which increased by increasing the efficiency to 81% at 20 h HRT, further it reduces to 81% at 24 h HRT as shown in fig..

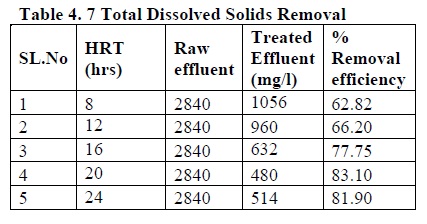

The biofilters can be best used to remove solids concentration from paper and pupl mill effluent. It was found from the fig. that removal efficiency is about 83% for 20 h, HRT. Further it can also be analyzed that increase in removal efficiency can be obtained by reducing the effective size of the filter material.

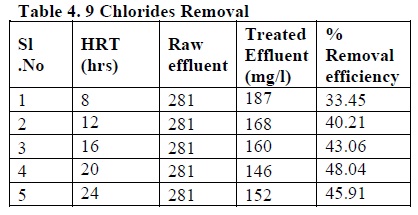

In chloride removal, the use of sand filters provide a good efficiency by removing about 50% of chlorides from the wastewater which meets the prescribed limit of CPCB standards. It can be observed from the graph that maximum removal was obtained at HRT of 20 h. This can be explained by the fact that maximum degradation happens within 24 hours.

1. The raw paper and pulp mill effluent is alkaline in nature having a pH value of 8.62.

2. It can be observed from the pH curves that, the pH value reduces by increasing the contact period.

3. Analysis for BOD and COD removal shows that the pollutant removal efficiency increases with increase in HRT till 20 hours, after that it is almost constant indicating the saturation level of the biological process.

4. Similar results were obtained for the removal of TS, TDS and TSS of maximum removal at 20 hour HRT of about 80%. It can be derived from the studies that reduction in the effective size of filter material can increase the % removal efficiency.

5. It is evident from the graph that percentage removal of chlorides for 8, 12, 16, 20 and 24 hours HRT is 33.45%, 40.2%, 43.06%, 48.04% and 45.90% respectively.

6. From the observations made from the analysis of performance of the bioreactor combined with quarry dust filter, the reactor has highest efficiency in removing the organic load from the effluent by about 83%.

7. The treatment used in the study is cost effective and can be used to remove the organic impurities from the waste water. And also significant reduction in turbidity and color can be observed by comparing the raw and treated effluent of paper mill.

1. The study can be carried out by analyzing the reactor performance for different industry waste waters having higher organic impurities.

2. The filler materials may be changed to other reusable waste materials for better performance of the reactor.

3. Different type of reactors can be fabricated to analyze the pollutant removal efficiencies for paper and pulp mill effluent.