Published on Nov 30, 2023

Solar drying of agricultural product is essential and most viable solution to the world’s food problem involves reducing the food loss, which occurs due to various reasons such as lack of suitable technology, improper cultivation and fertilization, lack of marketing channels, improper transportation, high post harvest losses, etc., causing a food loss from 10 to 40%. The food preservation by solar drying is the only method to reduce the food loss that is being adopted since many centuries.(M.V. Ramana Murthy ., 2008). Various types of solar dryers had been designed to overcome this problem. The type of dryer depends on the product and the drying process required for that particular type of product. Basically the drying process involves the migration of water from the interior of the product to be dried on to the surface for its evaporation and therefore it is a heat and mass transfer phenomenon (P.Barnwal et al., 2008).

The convective heat transfer coefficient is an important parameter which determines the heat and mass transfer. The convective heat transfer coefficient varies from crop to crop and the mode of drying. In case of green chillies the convective heat 1.31 W/m2 K, (Anwar et al., 2001a,b). The basic essence of drying is to reduce the moisture content of the product to a level that Prevents deterioration within a certain period of time. Drying is a dual process of -heat transfer to the product from the heating source. And mass transfer of moisture from the interior of the product to its surface and from the surface to the surrounding air (O.V Ekechukwu et al1999).

Drying is defined as a process of moisture removal due to simultaneous heat and mass transfer. It is a classical method of food preservation, which provides longer shelf-lighter weight for transportation and small space for storage. The drying process takes place in two stages. The first stage happens at the surface of the drying material at constant drying rate and is similar to the vaporization of water into the ambient. The second stage takes place with decreasing (falling) drying rate. The condition of the second stage is determined by the properties of the material being dried. Open sun drying is the most commonly used method to preserve agricultural products like grains, fruits and vegetables in most developing countries.

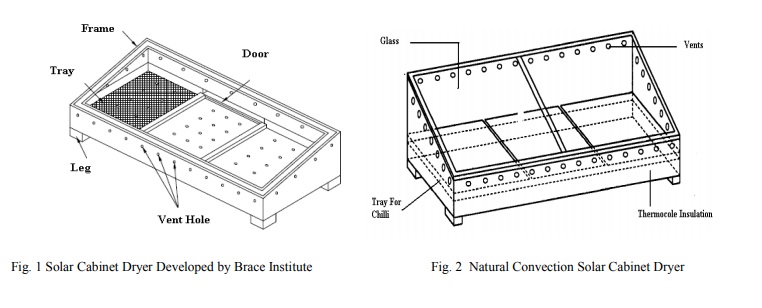

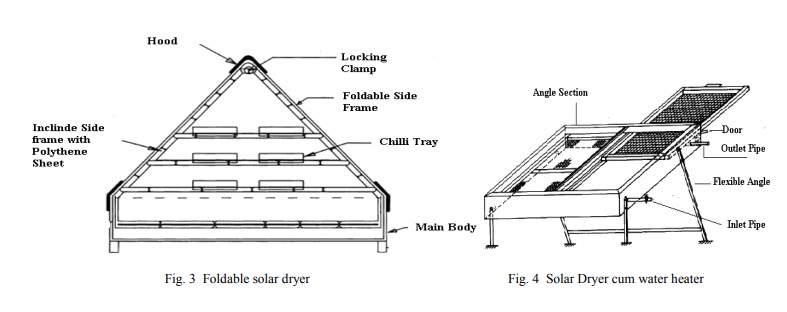

Such drying under hostile climate conditions leads to severe losses in the quantity and quality of the dried product. These losses related to contamination by dirt, dust and infestation by insects, rodents and animals. Therefore, the introduction of solar dryers in developing countries can reduce crop losses and improve the quality of the dried product significantly when compared to the traditional methods of drying such as sun or shade drying.

Most of the solar dryers make use of direct solar radiation to dry the products. In this project we are trying to concentrate the heat radiation onto the surface of highly conductive material like copper sheet which conducts the heat. Further the trapped heat is used to dry the products by convection and radiation mechanisms.

The main objective of this project is to develop an affordable solar based agricultural dryer for controlled drying of agricultural products such as seeds, rubber, fish, etc. without using any electrical power. This enables the dryer to be employed in remote areas where electrical access is impossible or expensive. For this purpose the dryer makes use of Fresnel lens to capture solar energy to heat the products placed in the closed chamber. The Fresnel lens has superior properties compared to normal double convex lens which increases the rate and efficiency of drying. Unlike the conventional drying technique this method is safer, economical, faster and hygienic.

Market research is carried out to understand the drying problem by interacting with the farmers and to evaluate the affordability of farmers. The various problems faced by farmers in drying of their products, including different types of drying requirements are determined.

The design of the prototype shall be developed using solid works. The methodology of the project is based on conversion of solar energy into heat energy with the aid of Fresnel lens. The high intensity heat energy thus developed is made to absorb by high conductivity copper sheet. The heat energy thus conducted is utilized to dry the agricultural products through convection. The dryer is provided with two assemblies namely Fresnel lens assembly and drying chamber assembly. Drying chamber assembly is provided with seed tray and water tray. The agricultural products are placed on the seed tray and the water dripping from the seed tray is collected in the water tray placed below it. The entire design is based on the focal length of the Fresnel lens. The design is such that the focal length of all three lenses falls on the same line.

The fire attachment is employed for drying process during off season (rainy season).

The prototype is then tested for its performance based on the time taken to dry the products as well reduction in humidity over the period of drying. The experiment is conducted periodically to assess the rate of drying with respect to change in atmospheric conditions. The testing is carried about with help of thermocouples and humidity sensors. The thermocouple is used to keep a track of drying chamber temperature, wall temperature and ambient temperature. Humidity sensors are used to record the humidity values inside the chamber as well as ambient. These inputs are connected to data logger and the readings are recorded for further analysis and optimization.

The outcome of the experiment is compared with efficiency and effectiveness of existing dryers. Further the design is optimized to increase the efficiency.

The optimization is done to reduce to heat loss from the chamber to surrounding etc.

The dryer consists of a rectangular box, made of mild steel sheet. A 10-cm portion of the box is fixed in the ground and bajra husk insulation (10 cm thick) is provided at the base. Four hollow bamboos are fixed in the walls of the dryer above the insulation and a number of holes are drilled in the bamboo to introduce fresh air into the base. Two wood-and-wire-mesh frames are fitted above the bamboo for placement of the produce to be dried. The dryer is provided with a double-sloped 0.3-mm PVC roof. Three aluminium chimneys painted black are provided at the top of the inclined roof as exits for hot air. Regulating valves are provided in the chimneys to change the passage area of circulating air. The moisture content was reduced from 86.3% to 4.1% within 9 days by the solar drying method; in contrast, it took 18 days to dehydrate the same quantity of chillies by open drying for 12kg of chillies.

The efficiency of drying can be further increased by providing an extra layer of insulation to the dryer body

The proposed solar powered dryer can be scaled to higher dimensions of Fresnel lens to increase the drying capacity

The dryer can be automated to place and remove the agricultural products by adopting electrically controlled conveyor system

The solar powered Agricultural dryer with lens assembly and drying chamber was successfully designed and fabricated

The dryer was made completely solar based by replacing hand operated fan system to solar panel powered electric fan

The drying capacity and efficiency was determined by collecting different drying properties

[1] Anwar, S.I., Tiwari, G.N., 2001a. Evaluation of convective heat transfer coefficient in crop drying under open sun drying. Energy Conversion and Management 42 (5), 627–637.

[2] Anwar, S.I., Tiwari, G.N., 2001b. Convective heat transfer coefficient of crops in forced convection drying – an experimental study. Energy Conversion and Management 42, 1687–1698.

[3] Atul Kumar, Tara C. Kandpal 2004. Solar drying and CO2 emissions mitigation: potential for selected cash crops in India ,Solar Energy 78 (2005) 321–329

[4] Barnwal P., Tiwari G.N., (2008), Grape drying by using hybrid photovoltaic-thermal (PV/T) greenhouse dryer: An experimental study, Solar Energy, doi:10.1016/j.solener.2008.05.012