Published on Nov 30, 2023

Mechanical forklift is an new and advance technique use in mechanical industry line. forklift lift or handle more material and transfer one place to another place. Because of forklift it is possible that a one operator is sufficient for material handling. When technology is improved advance fork lift was developed, they operate with the help of remotes.it requires an electricity as well as a cost of remote operated forklift is high so that a human powered forklift is introduce.

A population of India is very large so that the main of any industrial company to fulfill a customer requirement due to that extra workload in mechanical industry line. This work load causes increasing stresses on workers. Workers are prone to unhealthy condition. To minimize a stresses factor on a workers some material handling machines are developed.

This machine transfer a work from one station to other hence work is done in time So that we get more production as well as accuracy. This gives better production efficiency. Due to material handling machines we reduce cycle time of particular job by reducing handling, fixing and carrying time.

Design development and modeling forklift by Ugale Sachin, Salvi Tushar, Lanjekar Sachin, Kshirsagar Prashant fabricated a forklift by using ratio frequency technology. This makes it wireless and increase visibility as well as safety. A transmitter which are present in this forklift able to control a forklift from 15 feet we can not use this forklift more than 15 feet distance.

Chunshan when forklift is loading and unloading it is directly under all cargo weight and finished the goods fork, handling , lifting. It is mainly composed of door frame outrigger and cargo, guide wheel chain and lifting oil cylinder.

Aashish kumar L Sharnagat1, M.S.Tufail we developed of robotic forklift to handle palletized material using local sensing so that it needs electricity.

Design and development of human powered forklift by Sandip patil, Ayubkhan Pathan, Manohar Chavan, Sajid Shikalgar, Prof.B.Nangare Patil A small scale industry going towards high quality of product with minimum cost and also minimize material handling cost . so human powered forklift is better option. this forklift easy to operate with less cost and indirectly it save labor cost.

Matthew Sparkers[5] For companies trying to be sustainable and carbon neutral, warehousing and distribution can be difficult. It’s fine to make green products, but it is more difficult to find a green way to get them into store. If you are serious about reducing emission , and your product does not weight too much, then this human powered forklift may good option. You can move and lift pallets entirely with human power and get that gas or diesel forklift out of your warehouse

High Risk Work A Guide to forklift safety by Government of South Australia counter balance forklift are usually supported at three points called ‘triangle of stability’. The front left wheel the front right wheel and middle of rear axle at the pivot pin connected to the steer axle make an imaginary triangle. This is important because the centre of gravity must remain within this triangle of stability. If the COG fall outside the triangle the forklift will tip over.

Design And Structure Analysis Of Mechanical Forklift Using ANSYS Software by Prof. kshirsagar Prashant. R we study the structure analysis of the forklift using ANSYS software. Theoretical calculation is compare with ANSYS software analysis is done to verify due to this select the forklift material as mild steel due to high specific stiffness and strength. Lift by the fork it tried to deform and bend in a particular direction so in order to prepare design of forklift.

Material Handling Equipment Selection Using Weighted Utility Additive Theory by Prasad Karande, Shankar Chakraborty using weighted utility additive method to solve material handling equipment solution. This method is compare with drive by the past research with provide the its potentiality, applicability and accuracy to solve machining problem.

A small scale industry (SAI ENTERPRISES) having major problem related to cost of material handling system, they does not use automated device so that they use manually machines. The material handling like lifting of raw materials, transfer the finished product to final stage, transfer the one product from one department to other department so that overall cost required for material handling is increase. This cost affected on profit of company so that we avoid this problem we find solution to overcome above problem with the help of human powered forklift.

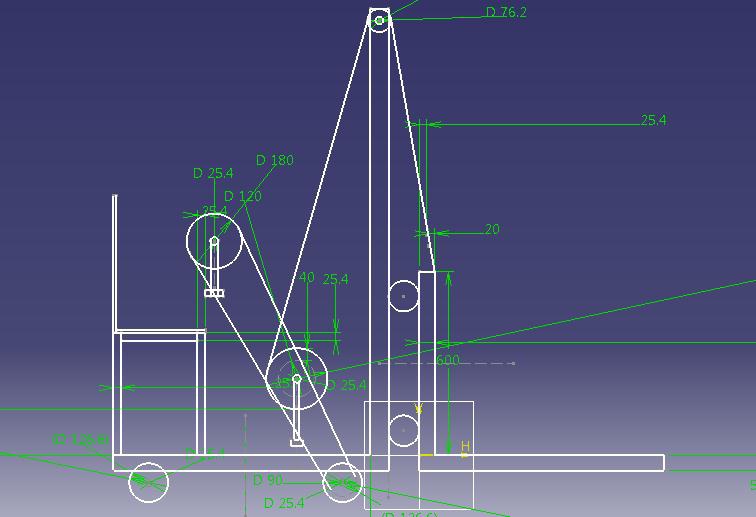

Human powered forklift consist of frame which made of steel square bars which are welded together to form structure. The wheels are provided for turning purpose the wheel is mounted on front axle. The rod is connected to front axle, with the help of this rod we turned front wheels. The chain and sprocket mechanism are provided to provided forward and backward moment of forklift which is place at back side.

The pedal is provided at middle side of forklift and rope and pulley are provided for lifting purpose. When operator operate a peddle a rope are wounded on pulley and load which are place which can be move upward at specific level. In this way by using various mechanical components like chain, sprocket, pulley, rope, We operate a forklift. Main special thing in our forklift is fully mechanical without supplying electricity or any battery source.

It is use for forward and backward moment and it also rotate in angle for turning of machine.

Rear wheels move only in forward and reverse direction.

Fork frame is made of mild steel. Fork works as lifting member.

-Bearing are mounted in between the body member and fork frame

Sprocket has 44 teeth, which transmit motion and power. Two sprocket are attached to two front wheel and two sprocket attached to handle.

Bicycle chains are used. Chains are use to transmit power from handle to front wheels for moving the machine.

It is used for lifting the weight, paddle are also used as handle for transmitting motion.

Pulley is mounted at top of body frame. It is used to support the wire

It is conclude that this machine is use for small scale industries. This machine operates within short period of time. Its operating cost as well as labor cost is reduce. It is mechanical device, does not required electricity as well as any external source of battery.

[1] R.P.KumarRompicharla – PG Student, Dr. K. Rambabu – Associate Professor,“Design And Analysis Of Drive Shaft With Composite Materials” Affiliated to Andhra University, Research Expo International Multidisciplinary Research Journal Volume - II, Issue - IIJune - 2012 ISSN: 2250 -1630.

[2] ISO. ISO Standard 2328:2007, Fork-lift trucks – Hookon type fork arms and fork arm carriages – Mounting dimensions. ISO, second edition, 2007.

[3]“Forklift Stability and Other Technical Safety Issues” Accident Research Centre Monash University Victoria 3800 Australia (Authors:J Lambert & Associates) an initiative funded by WorkSafe, Victoria. April 2003

[4] Rangaswamy, T.; Vijayrangan, S. (2005). “Optimal sizing and stacking sequence of composite drive shafts”.Materials science, Vol. 11 No 2.India.