Published on Nov 30, 2023

Here we have fabricated the pneumatic forging machine; it's a new innovative concept. Forging is the term for shaping metal by using localized compressive forces. Cold forging is done at room temperature or near room temperature. Hot forging is done at a high temperature, which makes metal easier to shape and less likely to fracture . Warm forging is done at intermediate temperature between room temperature and hot forging temperatures .

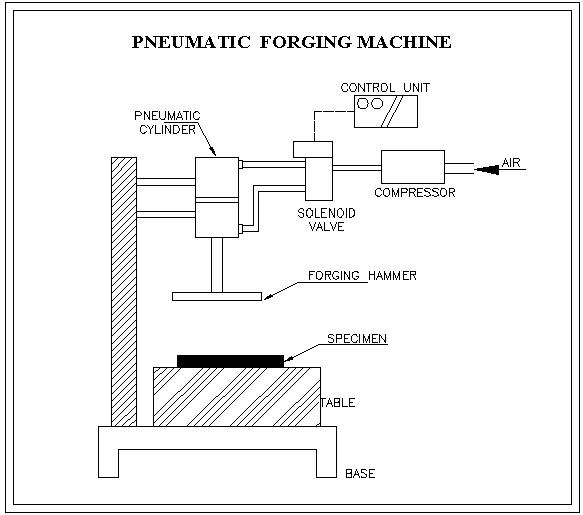

This machine has been mainly developed for metal forming to the required shape and size. In this machine we have using the pneumatic cylinder for forging the specimen. Pneumatic is air operated device. By doing the manual process it consumes more time and large amount of man power required for forging. By using this machine we can save the time and man power requirement in the industries

Here we have fixed the pneumatic cylinder on the column of the machine which is fixed on the base table. The forging hammers are fixed at the end of the pneumatic cylinder piston rod. The pneumatic cylinder is operated through the pneumatic energy (air). The air stored in a compressor the compressed air is passed to the pneumatic cylinder with the help of the solenoid valve.

The solenoid valves are operated through the control unit. The air enters on port one in the pneumatic cylinder to moves the forging hammer in downward direction. After the forging operation takes places the forging hammer will moves in upward direction.

While on the hammer moves in upward direction the port one will release and the air will be forced into the port number two. The two directions are controlled by control unit. During the movement the forging hammer forged the specimen to make it to the required shape and size. After the required number of strokes completed the forging process is stopped by the help of the control unit