Published on Jan 09, 2026

The transmission is a device that is connected to the back of the engine and sends the power from the engine to the drive wheels. An automobile engine runs at its best at a certain RPM (Revolutions Per Minute) range and it is the transmission's job to make sure that the power is delivered to the wheels while keeping the engine within that range. It does this through various gear combinations.

In first gear, the engine turns much faster in relation to the drive wheels, while in high gear the engine is loafing even though the car may be going in excess of 70 MPH. In addition to the various forward gears, a transmission also has a neutral position, which disconnects the engine from the drive wheels, and reverse, which causes the drive wheels to turn in the opposite direction allowing you to back up .

The key difference between a manual and an automatic transmission is that the manual transmission locks and unlocks different sets of gears to the output shaft to achieve the various gear ratios, while in an automatic transmission the same set of gears produces all of the different gear ratios. The planetary gear set is the device that makes this possible in an automatic transmission. Driving a manual transmission is especially painful in stop-and-go traffic, where you constantly have to change your gear state. You might also make the case that having to concentrate on shifting your transmission takes some of your attention away from the actual driving, which is dangerous, because you might be concentrating on your tachometer or your gearshift when you really should be focusing on the traffic. An automatic transmission bypasses these problems entirely .

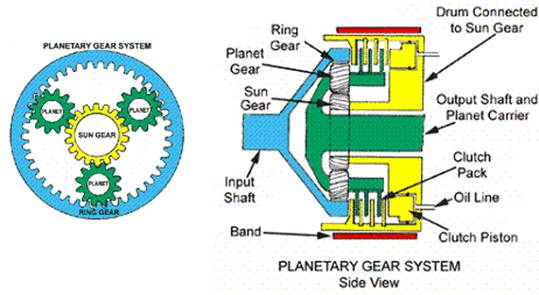

The automatic system for current automobiles uses a planetary gear set instead of the traditional manual transmission gear set. The planetary gear set contains four parts: sun gear, planet gears, planet carrier, and ring gear (see Figure 1 .) Based on this planetary set design, sun gear, planet carrier, and ring gear spin centrifugally. By locking one of them, the planetary set can generate three different gear ratios, including one reverse gear, without engaging and disengaging the gear set.

Normally an automatic transmission system has two planetary gear sets with different sizes of sun gears with their planet gears inter-meshed. Only one planet carrier is used to connect both sets of planet gears. This is called a compound planetary gear set. This design can generate four different gear ratios and one reverse gear.

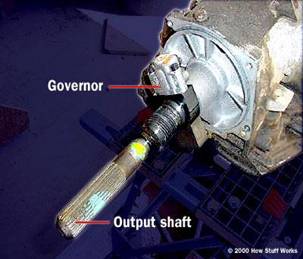

It uses a special transmission fluid sent under pressure by an Oil Pump through the Valve Body to control the Clutches and the Bands in order to control the planetary gear sets. Both the band and clutch piston are pressurized by the hydraulic system. The part connecting the band or clutches to the hydraulic system is called the shift valve, while the one connecting the hydraulic system to the output shaft is called the governor (see Figure 4 ). The governor is a centrifugal sensor with a spring loaded valve.

The faster the governor spins, the more the valve opens. The more the valve opens, the more the fluid goes through and the higher the pressure applied on the shift valve. Therefore, each band and clutch can be pushed to lock the gear based on a specific spin speed detected by the governor from the output shaft. To make the hydraulic system work efficiently, a complex maze of passages was designed to replace a large number of tubes

Unlike a manual transmission system, automatic transmission doesn’t use a clutch to disconnect power from the engine temporarily when shifting gears. Instead, a device called a torque converter was invented to prevent power from being temporarily disconnected from the engine and also to prevent the vehicle from stalling when the transmission is in gear. Consider two fans facing each other: when one of them is turned on and starts spinning, the other one will also start spinning at a lower speed. That’s because the first fan moves the air to drive the second fan to spin. This is the same idea as the torque converter of an automatic transmission system, except that it uses fluid instead of air as the transportation media.

A torque converter consists of four parts, a pump (impeller), turbine, stator, and transmission fluid. The pump is connected to the engine and transfers engine power to the transmission fluid. The fluid causes the turbine, which is connected to the input shaft, to spin. The stator is used to redirect fluid returning from the turbine before it hits the pump, again to increase the efficiency.

In this design, even when the vehicle is in gear but not moving (the turbine is forced to stop), the pump can still keep spinning without causing the engine to stall. When the vehicle speed is slow, the turbine is always spinning more slowly than the pump. However, when the vehicle moves at high speed, the turbine can spin at almost the same speed as the pump. Therefore, for modern cars, a “lock up” will occur between pump and turbine when the vehicle is at high speed in fourth gear, which makes the torque converter work more efficiently.

| Are you interested in this topic.Then mail to us immediately to get the full report.

email :- contactv2@gmail.com |