Published on Feb 14, 2025

Polyfuses is a new standard for circuit protection .It is re-settable by itself. Many manufactures also call it as Polyswitch or Multifuse. Polyfuses are not fuses but Polymeric Positive temperature Coefficient Thermistors (PPTC).

We can use several circuit protection schemes in power supplies to provide protection against fault condition and the resultant over current and over temperature damage. Current can be accomplished by using resistors, fuses, switches, circuit breakers or positive temperature coefficient devices.

Resistors are rarely an acceptable solution because the high power resistors required are expensive .One shot fuses can be used but they might fatigue and they must be replaced after a fault event. Another good solution available is the resettable Ceramic Positive Temperature Coefficient (CPTC) device. This technology is not widely used because of its high resistance and power dissipation characteristics. These devices are also relatively large and vulnerable to cracking as result of shock and vibration.

The preferred solution is the PPTC device, which has a very low resistance in normal operation and high resistance when exposed to fault. Electrical shorts and electrically overloaded circuits can cause over current and over temperature damage.

Like traditional fuses, PPTC devices limit the flow of dangerously high current during fault condition. Unlike traditional fuses, PPTC devices reset after the fault is cleared and the power to the circuit is removed. Because a PPTC device does not usually have to be replaced after it trips and because it is small enough to be mounted directly into a motor or on a circuit board, it can be located inside electronic modules, junction boxes and power distribution centers.

Technically Polyfuses are not fuses but Polymeric Positive Temperature Coefficient Thermistors. For thermistors characterized as positive temperature coefficient, the device resistance increases with temperature. The PPTC circuit protection devices are formed from thin sheets of conductive semi-crystalline plastic polymers with electrodes attached to either side. The conductive plastic is basically a non-conductive crystalline polymer loaded with a highly conductive carbon to make it conductive. The electrodes ensure the distribution of power through the circuit.

Polyfuses are usually packaged in radial, axial, surface mount, chip or washer form. These are available in voltage ratings of 30 to 250 volts and current ratings of 20 mA to 100A.

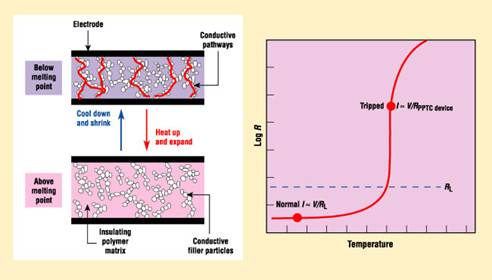

PPTC circuit protection devices are formed from a composite of semi-crystalline polymer and conductive carbon particles. At normal temperature the carbon chains form low resistance conductive network through the polymer. In case an excessive current flows through the device, the temperature of the conductive plastic material rises. When the temperature exceeds the device's switching temperature, the crystallides in the polymer suddenly melts and become amorphous. The increase in volume during melting of the crystalline phase cause separation of the conductive particles and results in a large non-linear increase in the resistance of the device. The resistance typically increases by 3 or orders of magnitude.

The increased resistance protects the equipment in the circuit by reducing the amount of current that can flow under the fault condition to a low steady state level. The device will remain in its latched (high resistance) position until the fault is cleared and power to the circuit is removed at which time the conductive composite cools and recrystallises , restoring the PPTC to a low resistance state and the circuit and the circuit and the affected equipment to normal operating conditions.

Thus a polyfuse acts like a self–resetting solid state circuit breaker , which makes it suitable for providing low-cost over-protection device. The resistance of polyfuse (expressed on log scale) at room temperature is a few ohms and rapidly increases above 110 degree Celsius

This surface mount polyfuse family of polymer of polymer based resettable fuses provides reliable overcurrent protection for a wide range of products such as computer motherboards, USB hubs and ports , CD/DVD drives , digital cameras and battery packs. Each of these polyfuse series features low voltage drops and fast trip times while offering full resettability. This makes each an ideal choice for protection in datacom and battery powered applications where momentary surges may occur during interchange of batteries or plug and play operations.

The SMD0805 with the industry’s smallest footprint, measuring only 2.2mm by 1.5mm, features four hold current ratings from 100mA to 500mA with a current interruption capability of 40A at rated voltage. Both the SMD1206 and SMD1210 series are optimized for protection of computer peripherals,PC cards and various port types.

Due to the automatic resetting of the polyfuse , these components are ideal for applications, where temporary fault conditions (eg: during hot plugging) can occur. The radial-leaded RLD-USB-series 709 is specifically designed for universal serial bus (USB) applications with lower resistance, faster trip times and lower voltage drops.

This type profile strap type polyfuse family of resettable fuses provides thermal and over charge protection for rechargeable battery packs commonly used in portable electronics such as mobile phones, notebook computers and camcorders.

Both Li-Ion and NiMH pack designs are enhanced with 0.8mm high form factor on the VTD-719 series. The LTD-717 series is optimized for prismatic packs and exhibits faster trip times- down to 2.9 sec at five times the fuse’s hold current rating.

Some of the critical parameters to consider when designing PPTC devices into a circuit include device hold current and trip current , the effect of ambient conditions on device performance , device reset time , leakage current in the tripped state and automatic or manual reset conditions.

Fig 2 illustrates the hold and trip current behavior of PPTC devices as a function of temperature. Region A shows the combination of current and temperature at which the PPTC device will trip and protect the circuit. Region B shows the combination of current and temperature at which the device will allow normal operation of the circuit. In region C , it is possible for the device to either trip or to remain in the low resistance state , depending on the individual device resistance and its environment . Because PPTC devices can be thermally activated, any change in the temperature around the device could affect the performance of the device . As the temperature around a PPTC device increases, and thus its hold current (I Hold) decreases.

The heat transfer environment of the device can significantly affect the device performance. In general , by increasing the heat transfer of the device , there is a corresponding increase in power dissipation ,time to trip, and hold current. The opposite occurs if the heat transfer from the device is decreased.

The time to trip of a PPTC device is defined as the time needed, from the onset of a fault current, to trip the device. Time-to-trip depends on the size of the fault current and the ambient temperature.

If the heat generated is greater than the heat lost to the environment, the device will increase in temperature , resulting in a trip event. The rate of temperature rise and the total energy required to make a device trip depends on the fault current and heat transfer environment.

| Are you interested in this topic.Then mail to us immediately to get the full report.

email :- contactv2@gmail.com |