Published on Nov 30, 2023

The Dairy wastewaters are generated from the cleaning and washing operation in the milk processing plant. Dairy wastewater is characterized by high BOD, COD and TDS Concentrations, and generally contains fats, nutrients, glucoses, methanol, lactose, sucrose, and detergents. The discharging of Dairy wastewater causes serious environmental problems. It reduces fossil fuel demand such as coal, oils and gases etc… The need for alternate eco-friendly fuel is increasing rapidly with the depletion of non-renewable energy resources. Microbial fuel cells (MFCs) represent a new form of renewable energy, which converts organic matter into electricity with the help of microorganisms present in dairy wastewater, while simultaneously treating the dairy wastewater. MFC generates electricity directly from various biodegradable substrates through microbial release of electrons to an electrode. Hence it is an ideal solution for sustainable nonrenewable source of energy. MFCs have gained significance in the last few decades due to their capability to produce energy, either as electricity or through hydrogen production, from renewable sources such as dairy waste and other similar waste sources.

The MFC consists of anode and cathode separated by a low cost filter media. According to the Logan Group of Pennsylvania State University (PSU), this technology can use microorganisms already present in dairy wastewater as catalysts in generating electricity while simultaneously treating dairy waste water. Some of the newest advances and future challenges are reviewed here with respect to practical applications of these MFCs for renewable energy production and other applications. Microorganisms have proven to be promising agents for electricity generation.

Keywords : DC-MFC, Dairy Wastewater, Copper Electrodes

To characterize the dairy wastewater.

To develop and fabricate a novel DC-MFC.

To evaluate the potential of DC-MFC to treat dairy wastewater.

To evaluate the potential of DC-MFC to generate electricity in the dairy wastewater.

1. Dairy wastewater collected from KMF dairy

2. Fabricated glass reactor

3. Copper electrode

4. Glass wool

5. Marble stones

6. 16-strands copper wire

7. Empty glucose bottle of 2.5 liter capacity

8. Aerator

9. Digital multimeter

1. MFC will be designed and fabricated using perplex glass. MFC set up consists of two chambers viz, anodic (anaerobic) and cathodic (aerobic) chamber.

2. These chambers are separated by a low cost filter media .

3. The reactor consists of two copper electrodes.

4. The dairy wastewater is fed into the anode chamber through inlet valve.

5. The microorganisms present in the dairy wastewater digest the organic matters and generates electrons and protons.

6. Electrons are transferred to the cathode chamber through an external electric circuit, while

7. protons are transferred to the cathode compartment through the filter media.

8. The oxygen is fed into the cathode chamber through aerator.

9. Electrons and protons are consumed in the cathode compartment combining with oxygen to form water.

10. An electrical current is formed from the potential difference of the anode and cathode.

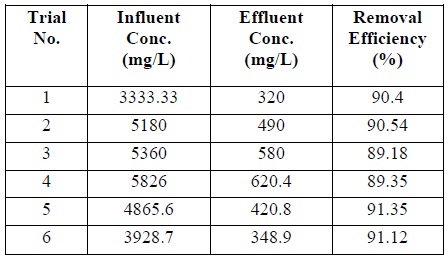

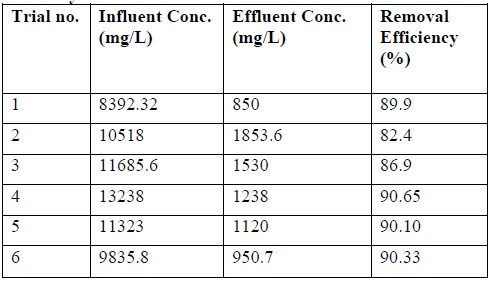

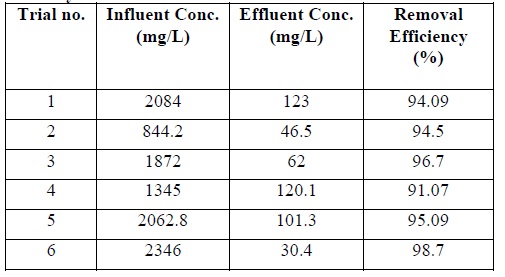

1. The maximum concentration of parameters of BOD, COD, TDS, Oil and Grease is sampled dairy wastewater were found to be 3333.33 mg/L, 8392.32 mg/L, 2084.00 mg/L and 4.10 mg/L respectively.

2. The design of the reactor has been done as per the design details using perplex glass and copper electrodes. It has been proved highly efficient.

3. After treatment, the parameters BOD, COD, TDS, and Oil and Grease in the effluent of dairy wastewater is found to be, 320 mg/L, 850 mg/L, 30.4 mg/L and 0.31 mg/L respectively.

4. The considerable Biochemical Oxygen Demand (BOD), Chemical Oxygen Demand (COD) removal efficiency is ranged between 90.4% to 91.12% and 89.9% to 90.33% respectively.

1. The reactor capacity could be scaled up to achieve higher electricity generation.

2. The overall efficiency of the reactor could be tested for different electrode materials.

3. The efficiency of the reactor to generate electricity could be tested for different types of wastewater.