Published on Nov 30, 2023

Basalt fibre which made from fibres of basalt rock is very much similar to the carbon and the fibre glass and have better physicomechanical properties and cheaper. One Kg of basalt reinforces is equal 9.6 Kg of the steel. They have many field applications and can replace many costly and rare materials. Its manufacturing process is very simple and raw materials are found virtually every country. Basalt fibres offer the potential to solve the largest problem in the cement and concrete industry.

Basalt Fibre which is also known as Basalt Fiber is a material which is made from the extremely fine fibres of the Basalt, which composed of Pyroxene, minerals plagioclase and Olivine. This is very much similar to the Carbon Fibre and the Fibre Glass, which is having better Physicomechanical properties than the fibre glass, but which is being significantly cheaper that the Carbon Fiber. It is also used as the fiber proof textile in the automotive industries and in the Aerospace and also can be used as a composite to produce the products such as the tripods.

Basalt is well known as the rock found in the virtually every country all around the world. Basalt Rock fibres has no toxic reaction with the air or water, are non combustible and the explosion proof. When in contact with the other chemicals they will produce no chemical reactions that may damage health or environment. The Basalt base composites can be replacing steel and known reinforced plastics. One Kg of basalt reinforces is equals to 9.6 Kg of the steel. There seems to be something quite poetic in using a fibre made from the natural rock to reinforce a material, which may quite reasonably being described as the artificial rock. Raw material for producing basalt fiber is the rock of a volcanic origin.

In the recent days, the various fibers develop and used in the construction, industrial and highway engineering. The steel is mainly used in that various application. Also fiber glass polythene fibers, carbon fibers, polyamide fibers are now developed and also used in construction, industrial and infrastructure development. In that list new one fiber is added, called, as basalt rock fibers.

Basalt originates from volcanic magma and flood volcanoes, a very hot fluid or semi-fluid material under the earth crust, solidified in the open air. Basalt is the name given to a wide variety of volcanic rock, which is gray. Brown or dark in colour, formed from volcanic lava after solidification.

The heavily thickened lavas contain olivine, clino-pyroxene (salite), plagioclase and opaque metal oxides. Plageocene and pyroxene make up 80% of many types of basalts. Table 1.1 shows the results of the chemical analysis of the basalt rock [2].

Because of good hardness and thermal properties, basalt has been used in the construction, industrial and highway engineering, in the form of crushed rock. It is used as surfacing and filling in roads, the floor tiles in the construction and as the lining material in the pipes for transporting the hot fluids. This can be major replacement to the asbestos, which possess health hazards by damaging respiratory systems.

However, it is not commonly known that basalt can be used in manufacturing and made into fine, superfine ultrafine fibers. Basalt is an alternative raw material for fiber forming because of its relatively homogeneous chemical structure, its large scale availability throughout the world, its freedom from impurities and of course, its ability to form fibers in the molten state.

Basalt fiber offer prospect of completely new range of composite materials and product. Low cost high performance fibers offer potential to solve the largest problem in the cement and concrete industry, cracking and structural failure of concrete. They have potential to high performance and cost effectively replace of fiberglass, steel fiber, polyamide fiber and carbon fiber product in many applications. 1 Kg basalt fiber replaces 9.6 Kg steel reinforcement.

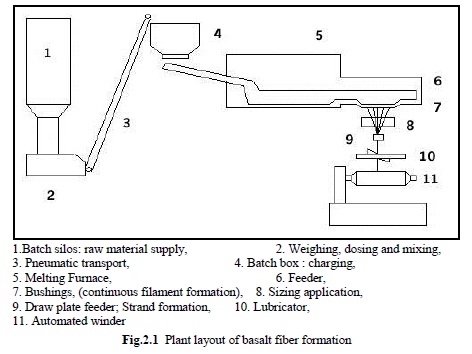

In many ways, basalt fiber technology is similar to glass fiber technology, except only one material, basalt rock. Basalt continues filaments are made from the basalt rocks in a single step process melting and extrusion process. Technological process of manufacturing basalt filament consists of melt preparation, fiber drawing (extrusion), fiber formation, application of lubricants and finally winding. Basalt fibers are currently manufactured by heating the basalt and extruding molten liquid through a die in the shape of fibers Crushed rock material are charged into bath type melting furnace by a dozing charger, which is heated using air gas mixture or electrically.

Crushed rocks are converted into melt under temperature 12850C to 14500C in the furnace bath. Molten basalt flows from furnace to feeder through feeder channel and feeder window communicate to recuperate. The feeder has a window with a flange connected o slot type bushing and is heated by furnace waste gases or by electrically. The melt flows through platinum-rhodium bushing with 200 holes which is heated electrically. The fibers are drawn from melt under hydrostatic pressure and subsequently cooled to get hardened filaments.

A sizing liquid with components to impart strand integrity, lubricity and resin compatibility is applied, and then filaments are collected together to form ‘strand’ and forwarded to take up devices to wound on forming tube.

By varying the drawing speed of the fiber and temperature of the melt, fibers of wide size range could be produced. For example, a drawing speed of 12m/s and nozzle temperature of 13250C a fiber of 7 micron were produced while at 4m/s and 12850C a fiber of 17 micron was produced.

Basalt fibers have different properties as follows-

Basalt fiber has excellent thermal properties to that of glass fibers. It can easily withstand the temperature of 12000C to13000C for hours continuously, without any physical change, which is similar to S2 glass fibers and carbon fibers.Unstressed basalt fibers and fabrics can maintain their integrity even up to 12500C, which makes them superior compared to glass and carbon fiber.

Basalt fiber has tensile strength 3000-4840 M Pa, which is higher than E-glass fiber. It has higher stiffness and strength than E-glass fiber. Basalt fiber has slightly higher specific gravity, 2.6 – 2.8 g/cc, than other fibers.

Basalt fibers have very good resistance against alkaline environment, with the capability to withstand pH up to 13-14. It also has good acid and salt resistance.

Basalt fiber has better corrosion resistance. It does not undergo any toxic reaction with water and air or gases also. Moisture regain and moisture content of basalt fibers exist in the range of less than 1%. Basalt materials have strong resistance against the action of fungi and micro-organisms.

Basalt material is extremely hard and has hardness values between 5 to 9 on Mohr’s scale, which results in better abrasion property. Even continuous abrasion of the basalt fiber-woven fabrics over the propeller type abraders do not result in the splitting of fiber by fracture and results only in breaking of individual fibers from woven structure which eliminates possibility of causing hazards.

Basalt fibers have natural raw material, which is basalt rock it does not cause any damage to the health. Basalt fiber has no biological hazards and solves waste disposal problems. It does not clog incinerator as glass. Hence, it is incinerator friendly.

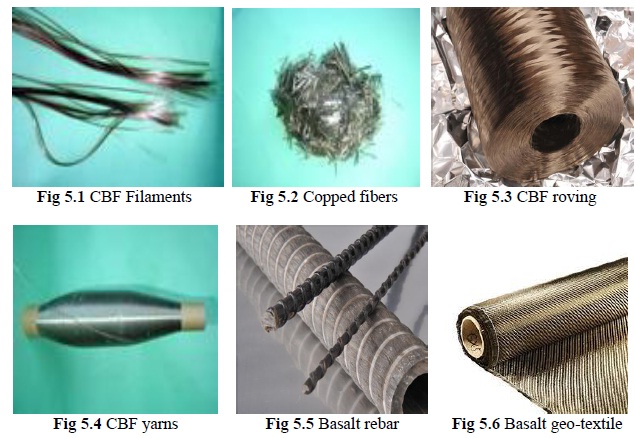

Figure 5.1 to figure 5.9 shows various products of basalt fibers. Continuous basalt filaments have following primary products such as Continuous basalt fibers, Chopped fibers, CBF roving, CBF yarns

By using these primary products the secondary products are produced such as Basalt rebar, Basalt geo-textile, Basalt mesh, Basalt fiber pipes, and Basalt laminates.

Requirement of the moderate strengthening in the civil structures & high fire resistance can be met with basalt fibers. Basalt filaments incorporated unidirectional rods are used as the reinforcement of concrete slabs in hydraulic engineering and construction in seismically hazardous regions. It is also used in reinforcement for bridges, tunnels, railway sleepers etc.

The basalt rebar consisting of 80% of basalt fiber with on epoxy binder offer better mechanical property to the reinforced concrete & are less expensive. Basalt rebar have same coefficient of thermal expansion (8 ppm/0C) as that of concrete, which increases the compatibility & performance in adverse conditions.

In the accelerated weathering tests, basalt fiber shows better results as compared to glass fibers. Exposed to 6000C for 2 hours also results in almost retention of 90% of normal strength while carbon fiber and glass fibers loss their volumetric integrity.

Chopped fibers are used in cement concrete which increases crack resistance and fracture toughness of concrete. It does not give any adverse effect in concrete mixing.

Basalt fibers can also be used in the interiors, partitioning of buildings, fire proof doors, and sound insulations for the building. They have better sound insulation property. It can act as a barrier in the frequency range up to 1800Hz to the extent of 80% to 95% [5]. It is also used as and warmed panels for construction of prefabricated houses such as roofing. Basalt fibers have better thermal insulating properties, almost three times than the asbestos. Basalt fabrics are used as fire blocking material in the public transport systems. Both woven as well as knitted fabrics are used for these applications.

It is used in port construction and sea platforms because of better chemical and salt resistance property and also for environment safety.

1) Basalt can be used in manufacturing and made into fine, superfine ultrafine fibers. Basalt is an alternative raw material for fiber forming because of its relatively homogeneous chemical structure, its large scale availability throughout the world, its freedom from impurities and of course, its ability to form fibers in the molten state.

2) Basalt Rock fibers have no toxic reaction with air or water, are non-combustible. When in contact with other chemicals they produce no chemical reactions that may damage health or the environment. So it is ecological friendly material.

3) Basalt rock fibers have new range of material in building construction, road construction, concrete industry and agriculture field. They have potential to high performance and cost effectively replace of fiberglass, steel and carbon fiber product in many applications. As per case study, concrete beam reinforced with BFRP bars achieved tensile strengths that are consisting with the relevant properties of the constituent materials. Concrete beams reinforced with BFRP bars behave in ductile manner exhibiting large deflection at failure.

4) Basalt is well known as a rock found in virtually every country round the world. Basalt rock is more in India (especially in Maharashtra). The cost of basalt is 10 times lower than that of raw materials for fiberglass. Basalt is more available than any other raw material.

[1] Dr. Patnaik Anil, “Applications of Basalt Fibers Reinforced Polymer (BFRP) Reinforcement for Transportation Infrastructure”, Developing a Research Agenda for Transportation Infrastructure – TRB, November 2009, 1-5.

[2] Dr. Sergey Osnos, “Basalt continuous fiber: development of technologies and equipment from the past to the present”, Basalt Fiber & Composite Materials Technology Development Company, China.

[3] Murray Allan D.,” Basalt Fibers for high-performance composites”, Allied composite Technologies LLC, 1-4.

[4] Saravanan D., “Spinning of rocks – Basalt fibers”, Institute of Engineers (India) Journal, volume 82, February 2006, 39-45.

[5] Sheldon G. L., “Forming fibers from basalt rock”, platinum metal review, 1977, 18-24.

| Are you interested in this topic.Then mail to us immediately to get the full report.

email :- contactv2@gmail.com |