Published on Jan 09, 2026

In conventional engines, fuel and air are mixed outside the cylinder. This ensures waste between the mixing point and the cylinder, as well as imperfect injection timing. But in the GDI engine, petrol is injected directly into the cylinder with precise timing, eliminating waste and inefficiency.

By operating in two modes, Ultra-Lean Combustion Mode and Superior Output Mode, the GDI engine delivers both unsurpassed fuel efficiency and superior power and torque. The GDI engine switches automatically between modes with no noticeable shift in performance. All the driver notices is a powerful driving experience, and much lower fuel bills. It's the best engine on the market.

• Ultra-low fuel consumption, which betters that of diesel engines.

• Superior power to conventional MPI engines

The Difference Between New GDI And Current MPI

For fuel supply, conventional engines use a fuel injection system, which replaced the carburetion system. MPI or Multi-Point Injection , where the fuel is injected to each intake port, is currently the one of the most widely used systems. However, even in MPI engines there are limits to fuel supply response and the combustion control because the fuel mixes with air before entering the cylinder. Mitsubishi set out to push those limits by developing an engine where gasoline is directly injected into the cylinder as in a diesel engine, and moreover, where injection timings are precisely controlled to match load conditions. The GDI engine achieved the following outstanding characteristics.

• Extremely precise control of fuel supply to achieve fuel efficiency that exceeds that of diesel engines by enabling combustion of an ultra-lean mixture supply.

• Very efficient intake and relatively high compression ratio unique to the GDI engine deliver both high performance and response that surpasses those of conventional MPI engines.

Ultra-low fuel consumption, which betters that of diesel engines.

Superior power to conventional MPI engines

For fuel supply, conventional engines use a fuel injection system, which replaced the carburetion system. MPI or Multi-Point Injection, where the fuel is injected to each intake port, is currently the one of the most widely used systems. However, even in MPI engines there are limits to fuel supply response and the combustion control because the fuel mixes with air before entering the cylinder. Mitsubishi set out to push those limits by developing an engine where gasoline is directly injected into the cylinder as in a diesel engine, and moreover, where injection timings are precisely controlled to match load conditions. The GDI engine achieved the following outstanding characteristics.

• Extremely precise control of fuel supply to achieve fuel efficiency that exceeds that of diesel engines by enabling combustion of an ultra-lean mixture supply.

• Very efficient intake and relatively high compression ratio unique to the GDI engine deliver both high performance and response that surpasses those of conventional MPI engines.

Lower fuel consumption and higher output: Using methods and technologies, the GDI engine provides both lower fuel consumption and higher output. This seemingly contradictory and difficult feat is achieved with the use of two combustion modes. Put another way, injection timings change to match engine load.

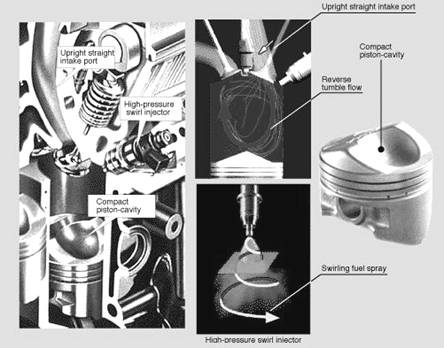

For load conditions required of average urban driving, fuel is injected late in the compression stroke as in a diesel engine. By doing so, an ultra-lean combustion is achieved due to an ideal formation of a stratified air-fuel mixture. During high performance driving conditions, fuel is injected during the intake stroke. This enables a homogeneous air-fuel mixture like that of in conventional MPI engines to deliver higher output.

Two Combustion Modes: In response to driving conditions, the GDI engine changes the timing of the fuel spray injection, alternating between two distinctive combustion modes- stratified charge (Ultra-Lean combustion), and homogenous charge (Superior Output combustion).

Under normal driving conditions, when speed is stable and there is no need for sudden acceleration, the GDI engine operates in Ultra-Lean Mode. A spray of fuel is injected over the piston crown during the latter stages of the compression stroke, resulting in an optimally stratified air-fuel mixture immediately beneath the spark plug. This mode thus facilitates lean combustion and a level of fuel efficiency comparable to that of a diesel engine.

The GDI engine switches automatically to Superior Output Mode when the driver accelerates, indicating a need for greater power. Fuel is injected into the cylinder during the piston's intake stroke, where it mixes with air to form a homogenous mixture. The homogenous mixture is similar to that of a conventional MPI engine, but by utilising the unique features of the GDI, an even higher level of power than conventional petrol engines can be achieved

| Are you interested in this topic.Then mail to us immediately to get the full report.

email :- contactv2@gmail.com |