Published on Nov 30, 2023

A plate freezer consisting of two plates connected in parallel and having a cooling load of 0.335 KW is to be designed. Installing formed tubing between two metal plates, which are brazed together at the edges, forms the plate surface evaporators.

The heat transfer takes place from the food to the freezer (chamber) surface through the air gap. As air is a bad conductor of heat, the freezing rate is low and time consuming. The freezing rate was increased by the development of the freezer. Only compactable foods can utilize this method. The Plate freezer under consideration is a multi plate freezer.

In the plate freezer there are two plates through which the refrigerant expands. The food is placed between the plates and are brought closer so that the food gets pressed to a pre-determined pressure. As the plates are in direct contact with the food, there is better heat transfer and hence the freezing rate is increased.

The plate used is copper plate, which is having a high heat transfer coefficient. The two plates are brought closer manually.

Compared to the conventional method of freezing this method takes only a Quarter of the time required to bring 1 kg of meat from 30 ºC to -20 ºC, the freezing rate is increased about four times. This is the most important reason why plate freezers are replacing conventional freezing equipments in the recent past

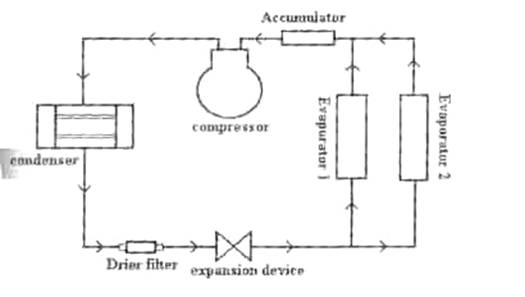

In the plate freezer the evaporator plates are arranged in parallel. The refrigerant after compression enters the condenser where the latent heat is rejected. The it is passed through a drier filter to remove moisture and dust particles from the liquid refrigerant. The expansion device used is capillary tube. The refrigerant enters the evaporator plates which are arranged in parallel.

An accumulator is provided before the suction line to prevent any liquid refrigerant entering the compressor. The four major equipments of the plate freezer, viz, the compressor, condenser, evaporator and expansion device, each have their individual characteristics which are functions of evaporator and condenser temperatures