Published on Nov 30, 2023

Piles are structures used to transfer loads from superstructure to the sub surface strata. When the subsurface stratum is water based or if we deal with a hydraulic structure, the piles are to be driven into water and under water strata. Piles used in underwater structures are often subjected to corrosion. There is no absolute way to eliminate all corrosion; but corrosion protection measures are employed to control the effect of corrosion.

Corrosion protection can be in different ways according to the environment and other factors. Forms of corrosion protection include the use of inhibitors, surface treatments, coatings and sealants, cathodic protection and anodic protection. The control measures explained in this are Protective coatings, cathodic treatment and application of Fibre Re-inforced Polymer (FRP) Composites

On steel piling in seawater, the more chemically active surface areas (anodes) are metallically coupled through the piling itself to the less chemically active surface areas (cathodes) resulting in a flow of electricity and corrosion of the anodic areas. General surface roughening occurs when these local anodic and cathodic areas continually shift about randomly during the corrosion process. Sometimes these active local areas do not shift position end, therefore, the metal suffers localized attack and pitting occurs. In general, the depth of pitting is related to the ratio of the anodic sites to the area of cathodic site in contact with the electrolyte (seawater). The smaller the anode area relative to the cathode area, the deeper the pitting

Before deciding on the methods for control of corrosion to be applied, conceptual and feasibility studies have been carried out. Typically, corrosion management can be divided into three major phases.

Phase 1 of the program is the programmatic assessment of the project. This phase is the planning stage for a corrosion management program to take place. It initiates the program to be implemented on structures that are found to be under the threat of corrosion. For the planning stage, three main requirements are sought, namely the strategy, budget and schedule needed to overcome the problem raised from corrosion of reinforcement. This is seen as an important part for an effective management program as feasibility studies are normally conducted to determine the serviceability of the structure after treatment.

Phase 2 of the program involves physical assessment and actual remediation. Inspections for severity of corrosion are conducted in this phase to determine what strategy or methods are most suitable to be applied. Development of corrosion control strategy would present more option to the management program. Remedial work would be carried out once the proper strategy has been recognized.

Phase 3 of the program mainly deals with future monitoring of the repaired structure. Currently and historically, most of the corrosion control programs are driven by response to incident or urgent need, rather than systematically identifying and managing the existing resources. This can be overcome by implementing internal or external monitoring system using current technology practiced in oil and gas industries

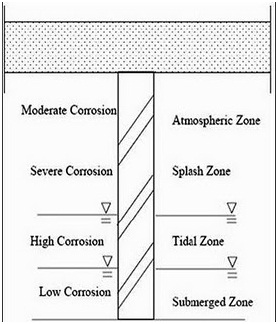

Examination of corroded marine piles reveals several distinct areas of attack. It is convenient to divide these areas into five zones, each having a characteristic corrosion rate as shown in Fig 2.1

In order to protect metals from corrosion, the contact between the metal and the corrosive environment is to be cut off. This is done by coating the surface of metals with a continuous non-porous material inert to the corrosive atmosphere.

Surface coatings are broadly classified into three

a). Metallic coatings

b). Inorganic Coatings

c). Organic Coatings

Individual coatings are formulated to perform specific functions and must be selected to become components of a total system designed for optimum results considering the environment and service expectations.

The different types of coatings used for under water piles are:

Steel structures that are permanently immersed in sea water, such as jackets in the area below the Splash Zone, are typically not coated for various reasons and protected solely by cathodic protection systems consisting of sacrificial anodes or impressed current arrays, which can be maintained as required by underwater contractors. Various anticorrosive pigmented primers are available, some that passivate the steel but the most effective are inorganic zinc silicate primers which essentially become anodic to the steel in a corrosion cycle. The primary advantage of this type of coating is that it will arrest rust creep, or undercutting of the coatings surrounding the damaged area, and confine corrosion to the point of the damage. These coatings also provide a high degree of resistance to heat and chemical spills.

Epoxies are generally more abrasion and chemical resistant than primers and topcoats and in this case protect not only the substrate itself, but the zinc primer as well from all of these detrimental factors. However, one drawback with epoxy coatings is very poor resistance to ultra violet from sunlight and most will chalk and fade rapidly. This leads to an erosion of the coatings’ film thickness, reducing the barrier protection of the system.

Polyurethane finish coats are generally acknowledged as providing optimum resistance to UV and high degrees of flexibility and chemical resistance. They also help to maintain a very high level of cosmetic gloss and colour retention and can be cleaned very easily, generally with low pH detergents and fresh water pressure washing. Although polyurethane finishes offer no real anticorrosive or barrier protection to the substrate they do provide a high level of protection to the integrity of the coatings system.

Zinc modified epoxy anticorrosives will provide a high level of service and are more tolerant to compromised surface preparation and ambient weather conditions provided the zinc loading of the formula is sufficient. Zinc rich epoxy is also most effective in maintaining damaged areas and breakdown of the coatings systems applied at new construction as it is compatible with alternate methods of surface preparation such as power tool cleaning and UHP Hydro Blasting.

Coatings specifically designed with anti-slip properties normally incorporate very course aggregates for an exaggerated profile. They are applied in very high film builds and normally without a zinc rich primer. When primers are required they are usually epoxy types.

The preferred technique for mitigating marine corrosion, based on historical performance and measurable results, is cathodic protection (CP) - the practice of using electrochemical reactions to prevent the corrosion of steel structures. The reason for increased acceptance: cathodic protection prevents corrosion on underwater structures.

In theory and practice, the implementation of a CP system is quite simple. Assuming you already have corroding steel in seawater, all you need is an anode, a power supply, and engineering talent. A protective circuit is accomplished between the anode, steel (cathode), power supply and electrolyte (seawater).

Though there is no absolute way to eliminate all corrosion on under water piles, there are some effective measures to control them. The cathodic protection is found to be quite simple to employ and mostly used in marine conditions. The protective coatings are used in vast and expensive structures. The FRP composites have many advantages over conventional methods such that they are light weight, possess high strength and chemical resistance and moreover have incomparable flexibility.

Of the various ways of wrapping of FRP composites, transverse wrapping is found to be the easiest as otherwise, the longitudinal pieces are awkward to handle and difficult to position. Bi-directional material is the best option. Scaffolding measures during the application of materials ensures safety and simplifies installation. Out of the two system of FRP application, the pre-preg system is easier to use. On-site FRP saturation can be problematic. High winds and high tides should be avoided during the process.

| Are you interested in this topic.Then mail to us immediately to get the full report.

email :- contactv2@gmail.com |